Express Yourself in 3D. Las impresoras 3D llevan la fábrica a casa. Albert Arjona se paga el máster con un negocio casero.

Imprime ecografías de embarazos con su impresora 3D. “Sesenta euros con IVA y portes incluidos”, dice el barcelonés. Desde que en 1995 a los estudiantes del MIT Tim Anderson y Jim Bredt se les ocurriera destripar una impresora para sustituir la inyección de tinta por un polvillo, las impresoras 3D han saltado de la gran industria al entorno doméstico. No es aún lo habitual, pero pronto lo será.

La acelerada caída de sus costes, a una velocidad que no conocieron el ordenador ni la impresora láser, hace prever que en una década la impresora 3D será tan popular en los hogares como lo es hoy la convencional. Gracias a la inyección de plástico líquido o polvo de arena, de una de estas impresoras salen prótesis dentales o utensilios para el hogar pero, a diferencia de la impresora convencional, su tamaño es fundamental.

En UltraSoun3dPrinted.com se ofrecen ecografías tridimensionales. Roger Uceda lleva 15 años trabajando en el futuro. Las impresoras 3D avanzan en el campo de la medicina, ahora con cartílagos. Las impresoras 3D siguen dando pasos adelante en una dirección donde quiere tener un papel importante: la medicina.

Hace tiempo vimos como se podían crear capilares sanguíneos o piezas para prótesis. Todavía queda mucho camino por recorrer pero van apareciendo avances a tener en cuenta. El último lo protagonizan los cartílagos. Top Ten of 3D Printing. Nanoscribe Will Sell a Micro 3-D Printer That Creates Tiny Structures in Seconds. Nanoscribe, a spin-off from the Karlsruhe Institute of Technology in Germany, has developed a tabletop 3-D microprinter that can create complicated microstructures 100 times faster than is possible today.

“If something took one hour to make, it now takes less than one minute,” says Michael Thiel, chief scientific officer at Nanoscribe. While 3-D printing of toys, iPhone covers, and jewelry continues to grab headlines (see “The Difference Between Makers and Manufacturers”), much of 3-D printing’s impact could be at a much smaller scale. Micrometer-scale printing has shown promise for making medical and electronic devices. Thiel says it should be possible to speed up his company’s microprinting technique even more in the future.

Nanoscribe plans to start selling its machine in the second half of this year. Printrbot jr. : Your kid's first 3D printer by Brook Drumm. **NEW :: JUST ADDED INTERNATIONAL REWARD!!

** (posted Dec. 1) The world of 3D printing is exploding, but many schools have special challenges that make it difficult to acquire a 3D printer. We need your help to sidestep these challenges and simply GIVE THEM TO SCHOOLS. Two 3D printers for $700 will be the seeds you can use to grow a community of Makers in your local school. The Printrbot jr. - the tipping point? Small. For Schools and Makers, alike. Education is one of my passions. Traditional public schools and young students are our chief target with this project, but we have heard from all sorts of Makers dreaming of what they could do with a 3D printer.

Sourcing parts and scaling your business is hard (we have done it) and can slow the process of delivering product. I have labored for months at Printrbot and now have the knowledge and some of the best sources in the world for the parts needed to build these bots. Micro 3D printer Kickstarter funding: $1 million in just one day. Micro, an unusually sleek 3D printer, is about to hit $1 million in funding on Kickstarter just a day after it started raising funds.

The project hits the sweet spot for anyone interested in 3D printing as it might be the first commercially viable $300 3D printer the world has ever seen. The Micro printer is notably light, weighing just 2.2 pounds. Micro is also doing far better on Kickstarter than Foodini, the nearly equally slick-looking food-printer that created a pretty respectable media splash, but has raised just under $60,000 so far. It’s possible that the pitch of “printing different shapes to encourage kids to eat healthy foods” needs some fine-tuning, especially in a world where people are clamoring for 3D-printed chocolate. Micro and Foodini aren’t the only popular 3D printers on Kickstarter, of course. 4D printing: Making things that make themselves. While some of us have only just got our heads round 3D printing and its potential, you might shudder at the thought of 4D printing but it’s already here.

The concept: 3D printed objects that seamlessly expand, fold and harden into different forms. The cynic’s first reaction is to label 4D a gimmick, pointing out that the fourth dimension is in fact time, however at the TED conference in Los Angeles, architect and computer scientist Skylar Tibbits showed us just how it works and it’s ingeniously simple: 4D allows objects to self-assemble and adapt. Self-adaptive objects While a 3D printer builds things up layer by layer, Tibbits has developed a technology where chunks of material start separated and then intelligently arrange themselves into a pre-programmed object, and furthermore, create objects that can change after they are first printed meaning they are self adaptive.

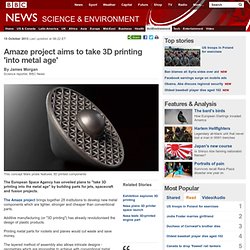

Amaze project aims to take 3D printing 'into metal age' 15 October 2013Last updated at 06:22 ET By James Morgan Science reporter, BBC News This concept Mars probe features 3D printed components The European Space Agency has unveiled plans to "take 3D printing into the metal age" by building parts for jets, spacecraft and fusion projects.

The Amaze project brings together 28 institutions to develop new metal components which are lighter, stronger and cheaper than conventional parts. Additive manufacturing (or "3D printing") has already revolutionised the design of plastic products. Printing metal parts for rockets and planes would cut waste and save money. Continue reading the main story.