RSR Electronix Express. (A COOPERTools Reprint) Purpose.

How to Solder: Through-Hole Soldering. How To Solder - Soldering Tutorial. Soldering is defined as "the joining of metals by a fusion of alloys which have relatively low melting points".

In other words, you use a metal that has a low melting point to adhere the surfaces to be soldered together. Consider that soldering is more like gluing with molten metal, unlike welding where the base metals are actually melted and combined. Soldering is also a must have skill for all sorts of electrical and electronics work. It is also a skill that must be taught correctly and developed with practice. Strip and Tin Wires Like a Pro. Place the thumb of the hand holding the wire on the pivot of the side cutters (picture 1), apply light pressure on the insulation of the wire with the side cutters and then push against the pivot with your thumb.

This should cause the blades of the side cutters to dig in to the insulation and push it back along the wire, breaking the insulation but not the core (picture 2). Definitely the trickiest bit of this Instructable, you just need a little bit of practice at knowing how much pressure to place on the insulation with the side cutters. It's really not hard, it just sounds hard. Hand Solder Training. What is the RIGHT Soldering Temperature? How to solder, Part1 (Irons - Tips - Solder - Flux - Wetting) 7.1.1 Soldering Basics. Soldering Process Soldering is the process of joining two metals by the use of a solder alloy, and it is one of the oldest known joining techniques.

Faulty solder joints remain one of the major causes of equipment failure and thus the importance of high standards of workmanship in soldering cannot be overemphasized. The following material covers basic soldering procedures and has been designed to provide the fundamental knowledge needed to complete the majority of high reliability hand soldering and component removal operations. Properties of Solder Solder used for electronics is a metal alloy, made by combining tin and lead in different proportions. You can usually find these proportions marked on the various types of solder available. With most tin/lead solder combinations, melting does not take place all at once. The plastic range of a solder varies, depending upon the ratio of tin to lead.

Flux Reliable solder connections can only be accomplished with truly cleaned surfaces. INTERVIEW WITH A SOLDER EXPERT. Multirotor Build Pt4: Soldering Tips (plus more motor advice) *EXPERT LEVEL* Solder Splice Tutorial TTC Avionics. Connection - Crimp Tools Comparison. How to Solder Bullet Connectors. Soldering Bullet Connectors. How to Solder Bullet Connectors By Innov8tive Designs. How-To: Soldering - TJinTech. Equipment and SuppliesBefore you can solder anything, you have to have the right equipment.

This includes the obvious items like a soldering iron and solder, but should also include heat shrink tubing, something to shrink the tubing (heat gun, lighter, match, etc), wet sponge, holding/clamping device, wire strippers and/or cutters, wire of various sizes and connectors. Now let me show you what I use. My tools and supplies include a Weller soldering station, a pair of needle nose pliers with some elastic webbing on them, 60/40 lead based solder, various heat shrink sizes and a lighter to shrink the tubing. Truth or Myth: Soldering From Above is Wrong. Soldering Basics - Popular Solder Connections. Sal Ammoniac How To!!! Hand Soldering Tip Temperatures. How hot are you setting your solder iron for hand soldering using solder wire or preforms?

If you are cranking up the solder iron temperature because you have transitioned to lead-free solders, think again. For both Sn63 and SAC solders, the suggested hand soldering temperature is 315°C. Using this temperature, the solder iron tip temperature is significantly hotter than the liquidus temperature of either alloy, although there is a 34° C differential or more between the liquidus temperature of these two alloys. Hand soldering relies on the thermal conduction of heat from the solder iron tip to a solder alloy, relying on Fourier's law for thermal transfer. The hot temperature of the solder iron tip will quickly rise the solder temperature to its melting temperature at this setting.

Hand Soldering Tip Temperatures. Essential Soldering Skills for Building Quadcopters. This article will teach you the specific soldering skills needed to build quadcopters.

These skills are easy to learn and very useful to know when building or fixing your own drone. Rather than provide just general guidance on soldering, this article will cover the specific skills you need. These skills will apply to building any size or type of quadcopter be it FPV, photography, racing, micro or otherwise. How to solder correctly (a not so brief lesson) Plus tips and more... [This tutorial was originally written with surface RC in mind, but I have updated it with info that is helpful to helis and other areas as well.

Over all, it is general enough to be of use in any soldering job you may find yourself in.] A lot of people have misconceptions about soldering, others are misinformed, some have no clue where to start, and many are bad at it whether they know it or not. Hopefully This post will help everyone solder better, have fewer issues and component failures, and have time for more fun because of it. I know perfect soldering is not such a big issue in a hobby, And most never give it a second thought, but a poor job can cause failures and frustration. Even if the soldering you did looks good, you may have damaged the circuits inside your components. Adventure Rider. Splicing Wires Discussion in 'The Garage' started by trscott, Nov 4, 2007.

Page 1 of 7 trscott, Nov 4, 2007 #1 trscott Been here awhile Joined: Mar 8, 2007 Oddometer: 346 Location: Newberg, Oregon I have gotten so much excellent help from others around here, I thought I would offer this tidbit. I know it isn't much, but I've been doing electrical work all my life and learned this from an old radio pioneer (my dad). Many people prefer crimped wire connections, but I personally much prefer a good soldered splice with double heat shrink. I will be putting up a long posting over in GSPOT to document the electrical mods I did on my BMW R1100GS, and as you will see there, I used quite a few of these splices on some very critical circuits. How-To: Soldering - TJinTech. Step 4: Soldering ESC Bullet Connectors.

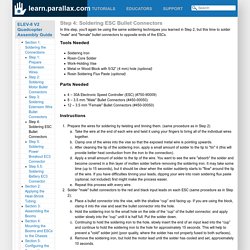

In this step, you’ll again be using the same soldering techniques you learned in Step 2, but this time to solder "male" and "female" bullet connectors to opposite ends of the ESCs.

Tools Needed Soldering IronRosin-Core SolderWork-Holding ViseMetal or Wood Block with 5/32” (4 mm) hole (optional)Rosin Soldering Flux Paste (optional) Parts Needed 4 – 30A Electronic Speed Controller (ESC) (#750-90009)8 – 3.5 mm "Male" Bullet Connectors (#450-00050)12 – 3.5 mm "Female" Bullet Connectors (#450-00050) Instructions Prepare the wires for soldering by twisting and tinning them. Hands-On Ham Radio™ "Ask Dr. Soldering - Part 6 - RC Quadrotor Helicopter - 2. You'll be doing a lot of soldering, especially with these rather large connectors. I'm writing this section because of the special connectors we'll be using requires some special soldering techniques. There's a lot of current going through these wires, and they have to withstand crashes and you yanking on them.

So you should do this properly. You need a good hot soldering iron for this, since the connectors are rather large and act as a heatsink. First, take a piece of wood, and drill some holes into it to hold your connector while you solder. Strip your wire, the length of exposed wire should be as long as the cavity in the connector's end.

Place the connector into the hole in the wood. Wait until the entire connector is cool enough to touch. If you are using the plastic housing, pull on the wire into the housing until the connector clicks into the housing. Also relevant links (not created by me): EPE "Basic Soldering Guide" Types of Iron? The Art of Soldering "Cold Soldering" - better than a traditional iron? Read our full review. Gas Soldering Iron review (legacy product) How to De-solder Desoldering Photo Gallery & Black Museum of Bad Soldering Electronics Soldering Guide Photo Gallery Gas Soldering Iron Review: Read how typical gas soldering irons work and see our full online view with photographs.

(Legacy product.) Soldering How-To. You don't have to take the NASA soldering course to build a winning BEST 'bot, but good soldering will keep your robot running throughout the matches. Solder school: Bullet connectors. Step 2: Soldering Motor Bullet Connectors. Over the course of the remaining Section 1 steps, you will solder all of the electrical connections for the ELEV-8. How To Solder - Soldering Tutorial.