Vitrum - the Glass Collection. Nixie tube. The ten digits of a GN-4 Nixie tube.

A Nixie tube, or cold cathode display,[1] is an electronic device for displaying numerals or other information using glow discharge. Although it resembles a vacuum tube in appearance, its operation does not depend on thermionic emission of electrons from a heated cathode. It is therefore called a cold-cathode tube (a form of gas-filled tube), or a variant of neon lamp. Such tubes rarely exceed 40 °C (104 °F) even under the most severe of operating conditions in a room at ambient temperature.[4] The most common form of Nixie tube has ten cathodes in the shapes of the numerals 0 to 9 (and occasionally a decimal point or two), but there are also types that show various letters, signs and symbols.

Each cathode can be made to glow in the characteristic neon red-orange color by applying about 170 volts DC at a few milliamperes between a cathode and the anode. Applications and lifetime[edit] Ice Tube Clock - Download files. Driver. Home-Brew Shaft Encoders. Home-Brew Shaft Encodersfor thePittman GM8712 Gearhead Motor by David P.

Anderson Pittman GM8712-31 19.1 V. DC Gearhead Some nice small DC gearhead motors recently appeared on the electronic surplus market, suitable for jack-rabbit size hobby robots of 5 or 10 pounds. Surplus DC gearhead motors suitable for hobby robots are very much "Targets of Opportunity. " I. Eric provided us with a synopsis of the motor's specifications, along with CAD drawings and dimensions of the motor itself and dimensions for a motor mount (both available in .dwg and .dxf formats).

Eric's synopsis: The spec sheet says of the 19.1V GM8712 gearmotor, with a 60.5:1 reducing gearbox: Gearmotor Data: Gearbox Efficiency 66%No-load Speed 128 RPM Motor Data: Continuous Torque (Max) 1.3 oz-inPeak Torque (Stall) 5.1 oz-inNo-load Speed 7729 RPM Winding Data: Torque Constant 3.06 oz-in/AResistance 10.80 OhmsNo-load Current 0.14 APeak Current (Stall) 1.76 A Eric continues: I take all that to mean (in theory) out the gearbox shaft: II.

Lead Screws: Starts, TPI, Threads and Linear Motion for CNC Machines. Single Starts, 2 Starts, 5 Starts, TPI, Lead, HUH?!?

I think it's about time to talk about lead screws. So, what is this lead screw that is always mentioned throughout this website. Lead screws also have all of these terminologies and esoteric language that I will demystify. Maybe you will also start to understand the math behind the linear motion and how different lead screws will provide various linear motion characteristics. Essentially, lead screws are simply screws that can provide linear motion when a turning motion is applied. The thread on a standard screw has only one groove that spirals around the shaft that pairs with a nut that reflects the same thread within the inside of the wall of the bore (hole). So what is threads per inch anyway... Yep, I said it, single start! Now, back to my minds eye explanation... How does this translate to speed? Now comes the easy math...

So you take the number of steps/turn and multiply that with the turns per inch (not threads per inch). Easy to Build Desk Top 3 Axis CNC Milling Machine. Homemade CNC Router The Builder's Guide (FREE!) This guide is still under construction!

Sections Introduction My Experience About Kits and Plans About This Guide The Guide Starts Here IntroductionSo you've decided to build a homemade CNC router or maybe youre just considering it, but where do you start? There are many advantages to owning a CNC router. Homemade CNC routers can cut and carve almost anything. For any hobbyist or DIYer, this opens many doors. Yes, you can build a CNC router that is just about as good as any other for a fraction of the retail price, and its not that difficult! There is also a great deal of flexibility when you design and build your own machine.

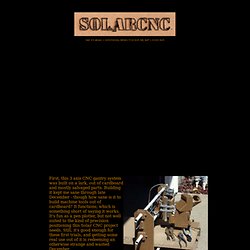

There are many reasons people want to build their own homemade CNC router. Home brew cnc. Laser cutter. Cardboard Solar CNC. Test #3 above: 1 inch/minute, letters 7/16 inch tall, kerf < 0.024 inch First, this 3 axis CNC gantry system was built on a lark, out of cardboard and mostly salvaged parts.

Building it kept me sane through late December - though how sane is it to build machine tools out of cardboard? It functions; which is something short of saying it works. It's fun as a pen plotter, but not well suited to the kind of precision positioning this Solar CNC project needs. Still, it's good enough for these first trials, and getting some real use out of it is redeeming an otherwise strange and wasted December. Mounted to the z-axis is "the cutting tool", which is the real focus of this project. The familiar part of the cutting head is a lens to focus sunlight down to the smallest burning point we can achieve. I ordered a couple bare glass lenses from Anchor Optics.

To get the sunlight to the lens, in a consistent downward orientation, we need the contraption above the lens. But I think it might work.