Artibot - a portrait painting robot. The architecture included an iPhone app to take a picture, downsample it to 100x100 pixels and convert it to grayscale. The image was then base-64 encoded and uploaded to a Google App Engine app that queues the images to be drawn. The arduino was fitted with an Ethernet shield so it can communicate to the server. To explain the software, consider the following drawing: In the above drawing, the angle alpha is the angle of the first arm from the y-axis, and angle beta is the angle of the second arm from the line the continues the first arm direction. These are the angles the servo motors use as their value or position. We made the conversion from (alpha,beta) space to the image space in the server code, to make the arduino part simpler. Homemade CNC Router The Builder's Guide (FREE!)

This guide is still under construction!

Sections Introduction My Experience About Kits and Plans About This Guide The Guide Starts Here IntroductionSo you've decided to build a homemade CNC router or maybe youre just considering it, but where do you start? There are many advantages to owning a CNC router. Homemade CNC routers can cut and carve almost anything. For any hobbyist or DIYer, this opens many doors.

Traceur/mini CNC/repstrap (imprimante 3D) low cost [Terminé] - 3D Print - Montages Mécaniques/Electroniques. Articulated plotting robot for €10. Easy to Build Desk Top 3 Axis CNC Milling Machine. CNCme. V Plotter Design. A V plotter is a minimalistic design which uses a pair of steppers, some string, and a pen head to create a plotter.

These are sometimes made by students or technology sector employees as a way to avoid "real work". In this article, I dig into the math behind these machines, and also write a program to calculate the configuration of a V setup needed to produce a working device. Requirements What is the optimal configuration of control lines for an area to be plotted? Obviously, we can't have a drawing area above the control lines — our friend gravity sees to that. Line Tension Calculation The below diagram shows a mass m suspended by two lines. To describe the horizontal forces along the X axis (in balance), we write: To describe the force m along the Y axis, caused by the weight of the plotter head assembly, we write: Solving these two equations in terms of tension, we get: and Note that the tension equations have denominators in common.

Angle Length Cartesian Conversion Law of Cosines. DiY. Homemade Router Laser CNC. In this page I will show you how I have build a Router Laser CNC using some part from old printers, a Epson Stylus 800 and another Epson Stylus Color II, (you can use your old printer).

Aplications: Cutting Paper. To make stencils for painting with airbrush.Wood and Cardboard Engraving. Write and paint in wood whitout ink.Plastic Engraving. To write in plastic without special inks.Plastic Cutting. We can start obtaining the X axis from the old printer. We will not use the other parts, as control board, we need change it by another CNC control board with stepper drivers. I have mounted it in a wood base. General view of the device. Transmission system for Y axis. Simple drawing robot / XY plotter. Hello, sorry for very newbie questions, I'm very new to all this.

I would like to build a robot which can draw curves with a pen. The size of drawing area would be something like 30 x 40 cm (A3), it would plot just in 2D so X and Y only. And for now, the pen could just either touch the paper or not (i.e. no Z, or pressure) and is just glued to the arm. I really would like it to be very precise (so it could draw straight lines or circles or Bezier paths, even very small ones, like 6 pt letters). My questions are: - What "kind" of robot do you recommend?

Building Your Own 3D Printer. Home-built 3D printers are booming.

In 2006 there were no such printers and 5 years later there are tens of thousands. There are currently hundreds of thousands of people wanting to start their own build waiting for the right moment to get started. The project that single-handily propelled home-built 3D printers out of nowhere is RepRap. It’s an open-source project meaning that all the information and design plans you’ll need are available free for all. Project CNC Router for all. DIY CNC Router. If you have any interest in purchasing a kit version of this machine please click the above button and complete the form so that I can gauge the level of interest.

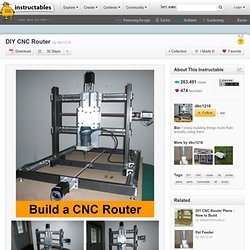

This instructable will show you how to construct a CNC Router that will allow you to cut 3-D shapes out of wood, plastic and aluminum using a standard hand held router. Recently I have noticed that more and more projects on instructables have involved the use of some sort of CNC machine, be it a laser cutter, 3d printer, milling machine, etc. I wanted to join this revolution of digital fabrication and start making my projects even better using these tools. So about a year ago I set out to find a way to make this possible and came to conclusion that a simple 3 axis CNC router would be the best option to get things going. I started doing some research and decided to design and build my own machine. DIY CNC Router.

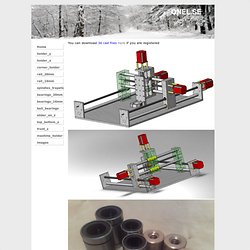

Www.onel.se. You can download 3d cad files here if you are registered.

Homemade DIY CNC Machine using Step Motors, Dremel, and EMC2. Tags: CNC, DIY, Machine, Motor Control, Robot, Robotics, Stepper Motor What is a CNC?

The abbreviation CNC stands for computer numerical control, and refers specifically to a computer “controller” that reads G-code instructions and drives a machine tool, a powered mechanical device typically used to fabricate components by the selective removal of material. In simple words, a CNC is a machine which is controlled by a computer, and used to fabricate 3D objects. This page will describe the process of building a CNC machine, from the design stage, the required materials and the process itself. Still confused? After seeing the movie, you must have understood how useful that kind of machine is for printing electronic circuit boards or manufacturing robot parts. Desktop CNC Mill Kit - Shapeoko 2. Product Details IMPORTANT NOTE REGARDING SHIPPING: Mechanical Kits have a 1 week lead time, Full Kits have an estimated lead time of 4-5 weeks Shapeoko 2 is a simple, low cost, open source CNC milling machine kit that can be built over a weekend.

Assembly is required before you can use it. Supported Rails. Local.gudel.com/uploads/pics/monoroll-gantry-img01_01.jpg. CNC Machine Building - Design. Components.