Anet A8 [3DPrint.Wiki] Assembly Instructions Assembly videos from Anet Assembly (Updated 2016/12/29.

![Anet A8 [3DPrint.Wiki]](http://cdn.pearltrees.com/s/pic/th/anet-a8-3dprint-wiki-154546014)

This video applies to A8 with new Z axis nut supports.) Part 1 Assembly (Updated 2016/12/29. This video applies to A8 with new Z axis nut supports.) Additional assembly instructions These are the most asked questions when assembling Calibration Calibration is normally not needed as this is carried out by the manufacturer and stored in the factory installed firmware.

Bed Center Calibration. How to 3D print peel-able supportive raft/base/platform with slic3r. First of all, let’s check out how easy and sweet it is to remove the supportive raft from your 3D print.

All you need to do is just to follow my instructions in the rest of this blog! The reason to print a supportive raft or base underneath your 3D model is obvious: the base absorbs any imperfections of your build plate; and if curling has to happen, it only affects the base, will not infect your model, so that your model bottom could retain flat. The raft, however, is not easy to come off if they are print in the same way as the real part. How to 3D print peel-able supportive raft/base/platform with slic3r. Create Your Own @font-face Kits. Black 3D Printer Filament - 1KG - ABS - 1.75mm - Go Inks.

Pure White - Zortrax Z-ABS Filament, Dream 3D. Product Description.

ABS Bed Adhesion Tips & Tricks. ABS Juice (or ABS Glue) is dissolved ABS filament in acetone.

Start with 2-3oz of acetone and 6-7 inches of ABS 3D printing filament, then adjust as needed. More ABS plastic dissolved in the acetone equals greater bed adhesion. The ideal consistency is thicker than water but thinner than milk. Slic3r Manual - The Important First Layer. Before delving into producing the first print it is worthwhile taking a little detour to talk about the importance of getting the first layer right.

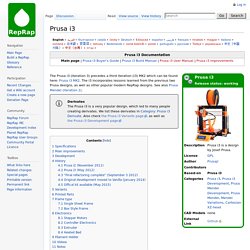

As many have found through trial and error, if the first layer is not the best it can be then it can lead to complete failure, parts detaching, and warping. There are several techniques and recommendations one can heed in order to minimise the chance of this happening. Level bed. How To Succeed When Printing With ABS. Last year, we published an article talking about how to succeed while printing with PLA.

While we still love printing with PLA, we neglected to write about the sister filament - ABS. Prepare your printer and get a notepad - the time has come. ABS is one of the most commonly used, and most versatile materials available in 3D printing today. If you're new to the scene though, it can be a bit daunting to start with. However, the payoff is worth it. Lego bricks made from ABS. How do I stop my model from lifting/warping? : 3D Printing Systems. Print Quality Troubleshooting Guide. Print Quality Troubleshooting Guide This guide is a great place to start if you are trying to improve the quality of your 3D printed parts.

We have compiled an extensive list of the most common 3D printing issues along with the software settings that you can use to solve them. Best of all, the guide uses a large collection of real-world images to make each issue easy to identify when examining your own 3D printed parts. So let’s get started! Thumbnail Overview Use the thumbnails below to identify the picture that most closely represents the quality issue that you are seeing in your own 3D printed parts. List View Each issue will now be listed one-by-one with details about what causes the problem and instructions for troubleshooting it. Not Extruding at Start of Print. Prusa i3. Prusa i3 Release status: working Specifications Main improvements The following is a list of the main improvements made upon the Prusa Mendel Iteration 2 Enhanced frame rigidity (prevents x-axis backlash) Easy assembly Parametric files for multiple sizes/bearings or bushings Development The development of the Prusa Mendel is hosted on github: History Prusa i2 (November 2011)

Slic3r Manual - Overview. This manual was sponsored by and written by Gary Hodgson Slic3r is a tool which translates digital 3D models into instructions that are understood by a 3D printer.

It slices the model into horizontal layers and generates suitable paths to fill them. Slic3r is already bundled with the many of the most well-known host software packages: Pronterface, Repetier-Host, ReplicatorG, and can be used as a standalone program. This manual will provide guidance on how to install, configure and utilise Slic3r in order to produce excellent prints. Complete ABS Profile Settings - 3D Printing. Quality Settings: The layer height of your print is very dependent on the nozzle size of your printer as well as the quality of the print you would like.

We run our quality settings for ABS extremely similar to PLA (in case you had already read our PLA Settings guide). A printer with a .6mm nozzle can go up to .4mm layer heights, and a part with .1mm layer heights will take twice as long as one at .2mm, so these factors are important to consider. Our standard quality print settings are at a .25mm layer height. We then hone in the retraction settings for ABS. Minimum Travel: 1.5mmEnable Combing: AllMinimal Extrusion Before Retracting: 0.005mmZ Hop When Retracting: .1mm. Slic3r is Nicer - Part 1 - Settings and Extruder Calibration. I have been using Slic3r for a few months now, it's coming along well and deserves lots more coverage, so here are a few notes and a very short guide to using it and what the settings mean - nothing difficult as it's already very easy to use and understand.In this Part 1 we will look at getting Slic3r running, calibrate the extruder and take a look at the Print settings.Part 2 will setup the printer, filament and print speeds along with doing some printing.Part 3 will experiment with low layer heights, hollow printing and any other features or limitations discovered.As of typing (6th Jan 2012) - Slic3r is at Version 0.5.7Please try it out, it's coming along very nicely and join in with the Slic3r RepRap ForumSlic3r WebsiteSlic3r on GithubDownload the package extract the zipped files and just run slic3r.exe directly from the directory, you don't need to setup anything unless you want to re-build it then you need the source from Github and citrus perl or Strawberry Perl.

Rich.