Formlabs - High Resolution Desktop 3D Printer. Technology and Design: the digital industrial revolution. Digital manufacturing and open-source design are revolutionising the way designers make their products, reports Dezeen editor-in-chief Marcus Fairs in this latest article from our series on technology and design supported by computing brand Intel.

Designers weren’t the stars of the Milan furniture fair this year, and nor was the furniture. Instead, machines stole all the headlines. At exhibitions across the city, robots were fabricating chairs, computerised metal presses were stamping out lamps and rapid prototyping machines were spitting out everything from coffee machines to food. Milan’s annual April design fair is the biggest and most important event of its kind in the world and it’s where journalists and cool-hunters converge to spot the latest trends. This year they were unanimous: technology is revolutionising the way designs are turned into finished products, heralding a new era of digitally driven production.

100% Design 2012 - Welcome to 100% Design. The Solar Sinter by Markus Kayser. Show RCA 2011: German designer Markus Kayser has built a 3D-printing machine that uses sunlight and sand to make glass objects in the desert.

Called The Solar Sinter, the device uses a large Fresnel lens to focus a beam of sunlight, creating temperatures between 1400 and 1600 degrees Celsius. This is hot enough to melt silica sand and build up glass shapes, layer by layer, inside a box of sand mounted under the lens. Endless by Dirk Vander Kooij at DMY Berlin. Un député veut réguler l’utilisation des imprimantes 3D. Les imprimantes 3D se développent à une telle vitesse que même les hommes politiques souhaitent prendre part au débat.

Un député UMP souhaite se pencher sur la question des droits d’auteur des objets imprimés en 3D. Pourquoi l'impression 3d peut créer de nouveaux business models. A l'aise dans son jean, ses baskets et ses lunettes à grosses montures, Bre Pettis , fondateur de Makerbot, l'une des principales sociétés d'imprimantes 3d (20% du marché mondial) s'enthousiasmait, dans une conférence de presse le 20 février à New York, sur son business en pleine croissance.

Si l'entreprise reste secrète sur ses chiffres, elle affirme avoir vendu 15 000 imprimantes depuis sa création en 2009, et emploie désormais 165 personnes dans ses locaux à Brooklyn. Michael Guslick, Amateur Gunsmith, Claims To Have Used 3D Printer To Make Functional Semiautomatic AR-15 Rifle At Home (PHOTOS) From pediatric prosthetics to drugs and guitars, 3-D printing is already revolutionizing the way we use, make and think about a plethora of products.

Now, a firearms enthusiast is claiming to have added yet another thing to the list: a functional AR-15 rifle, which he made at home using a 3-D printer and gun blueprints downloaded from the Internet. Last month, Extreme Tech reported that amateur gunsmith Michael Guslick had managed to "construct and shoot a pistol partly made out of plastic, 3-D printed parts. " Guslick, an engineer who operates under the moniker 'HaveBlue,' had previously announced in an online forum that he had successfully fired 200 rounds from his custom-made, 3-D printed .22 caliber pistol. Gun enthusiasts release open-source kits for 3D-printed Wiki Weapons. News: a group of libertarian activists in the U.S. plans to distribute open-source blueprints for homemade 3D-printed guns, provoking questions about the potential uses of the increasingly affordable technology.

Defense Distributed, the activist group led by Texas law student Cody Wilson, has just received $20,000 in funding for its Wiki Weapon project to create instruction kits for working guns. Individuals would be able to download the kits and use them to 3D-print their own weapons at home, sidestepping the need for a gun license.

News of the project comes just weeks after another American hobbyist became the first person to successfully build and fire a 3D-printed gun. Michael Guslick claimed to have fired 200 rounds from his .22 calibre pistol, which he made by fitting a 3D-printed plastic receiver – the only part of a gun that requires a license in the U.S. – to the other gun components, which don't have to be registered. 3D printing, laser cutting – design, make & build your own products with Ponoko. Manufacturing: The third industrial revolution.

THE first industrial revolution began in Britain in the late 18th century, with the mechanisation of the textile industry.

Tasks previously done laboriously by hand in hundreds of weavers' cottages were brought together in a single cotton mill, and the factory was born. The second industrial revolution came in the early 20th century, when Henry Ford mastered the moving assembly line and ushered in the age of mass production. The first two industrial revolutions made people richer and more urban.

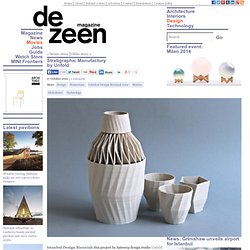

Stratigraphic Manufactury by Unfold at Istanbul Design Week. Istanbul Design Biennial: this project by Antwerp design studio Unfold explores how 3D-printed objects created from identical digital files can be as varied and unique as hand-made objects (+ movie + slideshow).

Above: objects produced by Unfold. Photograph by Kristof Vrancken Called Stratigraphic Manufactury, the project involved designing a range of bowls and vases on a computer and sending the digital files to small-scale producers around the world, who then manufactured them in porcelain using open-source 3D printers.