The Idiot’s Guide to Theory of Constraints (TOC) – Part II. At long last, here’s part II of our guide to TOC, in honor of the late Dr.

Eliyahu Goldratt, originally published in The Critical Path email newsletter on February 29, 2000. Did you miss Part I? Click here. In Part I, we focused on the basic root philosophy behind TOC to provide a jump-point for those interested in learning more. In part two of our guide, we list the major relevant books and provide a very brief glossary of TOC terms. THE GOAL – this is the book that started it all. ITS NOT LUCK – This book picks up with Unico’s Alex Rogo one year after the end of The Goal. 7 Deadly Sins Of Highly Inefficient Project Managers.

There are many deadly sins that managers can fall prey to if they are not careful, which can be really damaging for the business and for their team – such as failing to give feedback, being overly critical and micromanaging – but project managers in particular can also be in danger of committing the following sins within their role. 1.

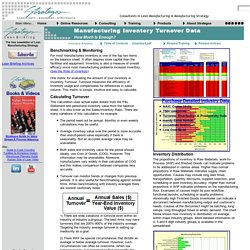

Manufacturing Inventory Turnover Data. Inventory Distribution The proportions of inventory in Raw Materials, work-In-Process (WIP) and finished Goods can indicate problems to be addressed in various areas.

Higher than normal proportions in Raw Materials indicates supply chain opportunities. Causes may include long lead times, transportation, quantity discounts, supplier selection, poor scheduling or poor inventory accuracy. Higher than normal proportions in WIP indicates problems on the manufacturing floor. Examples of causes might be poor workflow, functional layouts, scheduling or quality problems. Manufacturing Productivity Sales per Employee is one of many metrics for benchmarking productivity. This particular study focused on inventory rather than productivity.

Chris argyris, double-loop learning and organizational learning @ the encyclopedia of informal education. Contents: introduction · life · theories of action: theory in use and espoused theory · single-loop and double-loop learning · model I and model II · organizational learning · conclusion · further reading and references · links · cite.

Peter Senge - Navigating Webs of Interdependence. Innovation Consulting/Workshops/Training for product design/development,TRIZ,QFD,FMEA,DFSS, Design for Six Sigma. Home « CREAX. Spiral Dynamics. In spiral dynamics, the term vmeme refers to a core value system, acting as an organizing principle, which expresses itself through memes (self-propagating ideas, habits, or cultural practices).

The superscript letter v indicates these are not basic memes but value systems which include them. The colors act as reminders for the life conditions and mind capacities of each system and alternate between cool and warm colors as a part of the model.[2] Within the model, individuals and cultures do not fall clearly in any single category (color).

Factory Physics, Inc. - Bryan, TX. Podcast #25 – Mark Spearman, Factory Physics. 25_LeanBlog_Podcast_MarkSpearman_May22_2007. Theory of constraints. The theory of constraints (TOC) is a management paradigm that views any manageable system as being limited in achieving more of its goals by a very small number of constraints.

There is always at least one constraint, and TOC uses a focusing process to identify the constraint and restructure the rest of the organization around it. TOC adopts the common idiom "a chain is no stronger than its weakest link. " This means that processes, organizations, etc., are vulnerable because the weakest person or part can always damage or break them or at least adversely affect the outcome. History[edit] TW97_Know-your-Constraints. Theory of Constraints Overview Introduction. Let’s Start By Stopping For A Moment Slow down, block out the rest of the world for a moment, and take the time to consider the following.

Vanguard Home Page. Professor John Seddon: Seminal moments that informed the evolution of his systems thinking method. Cultural change is free. Systems Thinking: A Better Way To Make The Work Work: Professor John Seddon. John_seddon_inaugural_podcast. Performance beyond targets: leading radical change in the public sector: John Seddon. John_seddon_podcast. John Seddon Rekommendationer till svenska chefer som vill förbättra sin verksamhet. Systems thinking. Impression of systems thinking about society[1] A system is composed of interrelated parts or components (structures) that cooperate in processes (behavior).

Natural systems include biological entities, ocean currents, the climate, the solar system and ecosystems. Designed systems include airplanes, software systems, technologies and machines of all kinds, government agencies and business systems. Systems Thinking has at least some roots in the General System Theory that was advanced by Ludwig von Bertalanffy in the 1940s and furthered by Ross Ashby in the 1950s. The term Systems Thinking is sometimes used as a broad catch-all heading for the process of understanding how systems behave, interact with their environment and influence each other.

Russell L. Ackoff. Russell Lincoln Ackoff (/ˈækɒf/; 12 February 1919 – 29 October 2009) was an American organizational theorist, consultant, and Anheuser-Busch Professor Emeritus of Management Science at the Wharton School, University of Pennsylvania.

Ackoff was a pioneer in the field of operations research, systems thinking and management science. Biography[edit] Russell L. Ackoff was born on February 12, 1919 in Philadelphia to Jack and Fannie (Weitz) Ackoff.[1] He received his bachelor degree in architecture at the University of Pennsylvania in 1941. After graduation, he taught at Penn for one year as an assistant instructor in philosophy.

From 1947 to 1951 Ackoff was assistant professor in philosophy and mathematics at the Wayne State University. Video of Dr. Russell Ackoff Discussing Systems and Pieces. On weekends, I like to share videos or fun stuff that gets us thinking.

Today, I’m sharing a video with the legendary Dr. Russell Ackoff where he’s speaking at a session moderated by Clare Crawford-Mason, the producer of the outstanding video Good News…How Hospitals Heal Themselves on Lean and systems thinking. Ackoff makes important points in the video, but he starts with one of the funnier (and unexpected) speaker openings I’ve seen:

A Theory of a System for Educators and Managers. The Deming Institute. Joseph M. Juran. Early life[edit] What is Lean. The core idea is to maximize customer value while minimizing waste. Simply, lean means creating more value for customers with fewer resources. A lean organization understands customer value and focuses its key processes to continuously increase it. The ultimate goal is to provide perfect value to the customer through a perfect value creation process that has zero waste.