Thinglab - Independent UK Experts in 3D Printing and 3D Scanning - Full Solutions and Services in the United Kingdom Schallplatte aus dem 3D-Drucker - 3Druck.com - alles über 3D-Drucker und Digital Fabricator Die Schallplattentechnologie ist zwar nicht mehr die jüngste, könnte aber schon bald wieder Auftrieb von unerwarteter Seite bekommen. Der Entwickler Pittance produzierte mithilfe von Shapeways 3D-Drucker eine funktionsfähige Schallplatte. Auf Basis eines Spielzeug Plattenspieler von Fisher-Price, entwickelte Pittance sez eine funktionsfähige Schallplatte die mithilfe vom 3D-Druckservice Shapeways produziert wurde. Die “grobe” Version einer Schallplatte trägt die manuelle “Tonspur” des Songs ”Still Alive” und wurde vollständig aus Kunststoff gedruckt. Zwar klingt der Song noch nicht nach ernsthafter Konkurrenz für die Musikindustrie, zeigt aber die erstaunlichen Fähigkeiten heutiger 3D-Drucker. Links: Shapeways via boingboing, (c)Foto: Screenshot von Shapeways.com Update 03.09.2012 – Erstelle deine eigene Fisher Price LP Instructables User fred27, bietet nun einen eigenen “Fred´s Fisher Price Record Editor” der das Produzieren von Fisher Price´s LPs mit dem 3D-Drucker ermöglicht.

geometries - 3d printing and rapid prototyping > 3D-Printer > products_overview 3D Printing Roadshow 2014 In the new economy status quo is unacceptable. Customers demand more creativity and quality. Join the Digital Manufacturing Revolution. Injection Molding Prototypes Injection molders: Low-volume production is fast and affordable when you 3D print molds in-house. Gain certainty and agility by testing parts in production materials with your normal process. Learn more Connect With an Expert Curious about 3D printing? A local expert from our global network of partners is ready to personally welcome you to a 3D printed world. Find a Reseller

Adesina - En RepRap Mendel 3D-Printer - Aida printer vakkert! - Forum - Hardware Først en liten guide til hvordan man spleiser sitt eget belte til z-aksen. Merk opp lengden du vil ha og subtraher nødvendig overlapping, jeg tok ca 4 cm. Ta en stykk stasjonær båndsliper og kjør i vei. Først den ene siden. Og så den andre siden. Lim deretter sammen med tre små dråper superlim. Pakker ankommet med elektronikk. Jeg har vært flittig på besøk på min lokale post i butikk i det siste. Har blant annet fått ekstra motorer i hus. Elektronikken fra Tech Zone er også kommet i hus. De er knøttsmå i forhold til originaldesignet! Litt førstehjelp måtte til på et par av de optiske stopperne. Og selvfølgelig måtte det lages en custom monteringsplate ... ... og en custom power supply. Mine erfaringer med elektronikken. Det finnes ingen detaljert guide fra produsenten til dette elektronikksettet, men brukerne har begynt å få i gang mye bra informasjon på wikien: Tech Zone remix how to. Problemer oppstod først når jeg skulle koble opp extruderen. Hvem er det som lever? (Stort bilde).

NASA forscht an Contour Crafting am Mond - 3Druck.com - alles über 3D-Drucker und Digital Fabricator Die Raumfahrtorganisation NASA hat bereits vor kurzem den Einsatz von 3D-Drucker auf der internationalen Space Station überlegt. Damit könnten jederzeit Ersatzteile und Werkzeuge auf der Raumstation selbst produziert werden. Einen Gedanken weiter geht nun die Idee mithilfe von Contour Crafting komplette Gebäude am Mond zu Erstellen. 26.01.2012 – Der ortsunabhängige Einsatz von 3D-Drucker könnte sich zukünftig als weit größerer Vorteil erweisen als gedacht. Geht es nach Untersuchungen der NASA könnten in Zukunft komplette Gebäude mithilfe von 3D-Drucker am Mond erstellt werden. Contour Crafting Beim Contour Crafting arbeitet man am großformatigen Einsatz der 3D-Druck Technologie. Auch wenn sich bei einer solchen Anwendung am Mond noch eindeutig um Science Fiction handelt, ist die Idee für die NASA durchaus interessant. Da sich die benötigten Rohstoffe bereits vor Ort befinden, könnte man sich die komplizierten Transportwege sparen. Links: (c) Bild: Screenshot NASA.com Link zum Paper

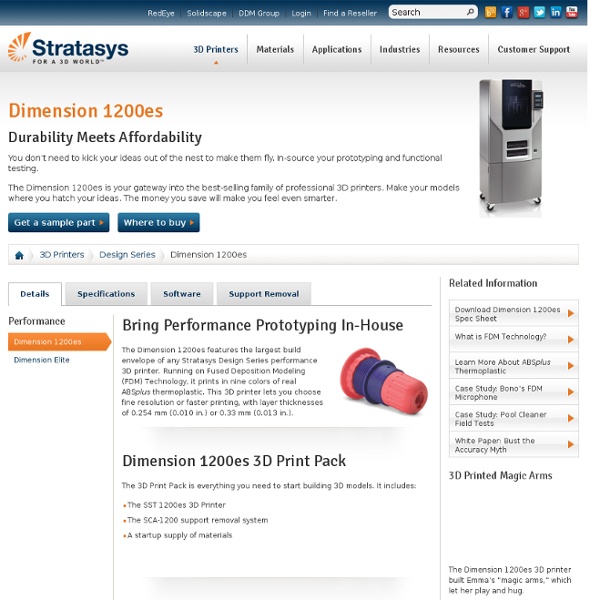

3D Printers & 3D Production Systems | Stratasys Products The Stratasys Idea Series levels the playing field by bringing professional 3D printers to individuals and small teams, accelerating creativity. Making the leap to world-class 3D printing at such a low cost is a revolution on its own. If you’ve ever taken a 3D prototype for a test spin before production, you already know its impact. Cut turnaround time and increase quality by building prototypes right under your own roof with Stratasys Design Series 3D printers. Rethink the factory from the floor up. The Stratasys Production Series is built to streamline manufacturing while maximizing your possibilities — handling the largest prototypes and accurate low-volume parts with agility. Because Stratasys believes the future of dentistry is digital, we’ve designed a 3D printing solution for almost every dental need. Learn about 3D Printing 3D printing is a way to create physical objects directly from digital files. Technologies

Blog: A new approach to printing metals There have been numerous attempts to print conductors. Fab@home, Ed Sells and myself have all tried it previously with very limited success. Whilst I've been able to print a basic circuit from solder, we were unable to achieve the resolution to produce anything but the most simplistic circuit board. Forrest Higgs and others have tried to identify a useful non-metallic conductive material but conductivity has always been fairly poor. Months ago I blogged about using Nickel Carbonyl powder for exactly this purpose. I did actually make filament using this composite material using the old technique of casting into silicone tubing. Fortunately non-eutectic alloys also offer this ability to have solid elements suspended within a molten liquid. After some thought I proposed that our ideal material would have a similar melting point to PLA/ABS such that when deposited on top a minimal amount of damage. I decided to go for an alloy of tin, indium and bismuth few a few reasons.

VRZ1: Das Design-Fahrrad aus dem 3D-Drucker - 3Druck.com - alles über 3D-Drucker und Digital Fabricator Nach EADS stellt nun auch eine deutsche Designmanufaktur namens Vorwaertz ein Fahrrad aus dem 3D-Drucker vor. Bei diesem Design-Projekt wurden sämtliche Stahlmuffen des Fahrrades mittels 3D-Drucker via Laser Sintering aus Stahl gedruckt und anschließend noch händisch nachbearbeitet. Die Muffen wurden anschließend mit dem Carbonfaser Rahmen verklebt. Das Resultat ist das hübsche Designer Bahnrad VRZ1. Bereits letztes Jahr stellte der europäische Flugzeugbauer EADS ein komplett gedrucktes Fahrrad aus Nylon mit dem Namen “Airbike” vor. Links: Quelle: Notcot.org

3D Candy Printing: An Interview with Designer Marcelo Coelho - Food Three-dimensional printers are getting a lot of hype at the moment. In February, MakerBot Industries started shipping its Thing-o-Matic desktop 3D printer, which, at just $1,225, "democratizes" 3D printing, allowing you to "live in the cutting-edge personal manufacturing future of tomorrow!" The same month, the typically restrained Economist headlined a story "Print me a Stradivarius: How a New Manufacturing Technology Will Change the World." Business Insider even called it "The Next Trillion Dollar Industry." The idea, for those of you who aren't familiar with it, is pretty simple. And people are already using the technology to print all sorts of things—pesticide-free plastic bug repellents, new ears, and videogame cars. They're also printing food. For example, both the BBC and the CBC have recently reported on the 3D food printer being tested at Cornell University's Computational Synthesis Lab (CCSL). Coelho: We started by looking at what was possible using real world technology.

DIY High Resolution 3D Printer Even though 3D printers have become mainstream and costs have declined, most cannot create a fine level of detail when printing. For rapid prototyping, you can fabricate one yourself such as the High Resolution DLP 3D Printer. Homemade yet still turns out impressive results. The 3D printer uses a Digital Light Processing chip with a high resolution video projector to render each layer of the image on a resin which is cured by a UV laser layer by layer. Each 0.1 mm thick needs about 8 seconds to cure. As the photos show, the high resolution DLP projector renders pretty accurate results. Popular 3D Printer Projects: Interactive Fabrication » Fabricate Yourself Fabricate Yourself is a project that documented the Tangible, Embedded and Embodied Interaction Conference. Usually we think of documentation in terms of text, photography and video, but given the tangible theme of the conference we decided to engage the community by capturing and fabricating small 3D models of attendees. This enabled us to build a tangible model of the event and fabricate it piece by piece during the conference. Attendees firstly capture their favorite pose using a Microsoft Kinect. The depth image from the Kinect is processed into a mesh and displayed onscreen in real-time. Dovetail joints are automatically added to the side of the models so they can be snapped together. The STL files were printed using a Dimension uPrint 3D printer kindly provided by Stratasys. Below you can see the models packed on to the 3D printing base. As we wanted to be able to fabricate a large number of models, we kept the size of the pieces down to approximately 3x3cm. Created by Karl D.D.