Mojo Discover the Magic of Mojo A 3D printer so brilliant, it could have designed itself. No need to leave your chair — Mojo prints professional-quality models at your desk. It’s as simple to use as a document printer, yet powered by Fused Deposition Modeling (FDM) Technology to build spot-on, functional concept models and rapid prototypes in ABSplus thermoplastic. With the lowest price, fastest build and finest layers of any Idea Series 3D printer, Mojo’s good vibes inspire boundless creativity. The ready-to-run Mojo 3D Print Pack arrives equipped with everything designers, engineers or educators need to start 3D printing: The Mojo Desktop 3D Printer Startup supply of materials and bases Mojo Print Wizard and Control Panel software WaveWash 55 support removal system Image Gallery Materials and Bases Mojo uses QuickPack Print Engines, which contain and deliver the model and support materials to build your 3D printed parts. Modeling bases provide a smooth surface on which your models grow.

TAZ 3 3D Printer | lulzbot.com Shipping and Payment InformationTAZ is currently only in stock and available to ship from our London, UK distribution center. Stock in other locations will be available again in 1-2 weeks. The evolution of desktop 3D printing continues with TAZ 3, LulzBot’s top-of-the-line, highest quality printer to date. Merging technical expertise with design sensibilities, TAZ is for inventors, entrepreneurs, design engineers and prototypers — bring your ideas to life with TAZ . Aleph Objects, Inc. is a fully Libre/Open Source Hardware company. If a picture tells a thousand words, a 3D printer can tell the whole story. TAZ is engineered for quality and tested for the long haul. TAZ is one of the few desktop 3D printers that can print with more than just your run-of-the-mill plastic. The TAZ 3 now comes with a graphic LCD controller for printing directly from an SD card! The TAZ is currently only shipping with North American AC power cables from the US.

MIT Media Lab's Brilliant New Logo Has 40,000 Permutations [Video] To honor 25 years of backseat-driving robots and vision-scanning iPhones and touchscreen-keyboard-3-D-display hybrids, the MIT Media Lab tapped Brooklyn-based designers (and erstwhile Media Lab rats) E Roon Kang and Richard The to dream up a fresh visual identity. The result is pure, unadulterated Media Lab: an algorithmic logo that generates a sui generis image for each of the Lab's sui generis brains. (Cue spazzo nerd gasp.) It's darn clever stuff. As The tells Co.Design, the Media Lab never really had its own logo. The basic idea here is that the logo has three intersecting spotlights that can be organized in any of 40,000 shapes and 12 color combinations using a custom algorithm. Folks select a design on a web-based platform, and once they've made their choice, no one else can poach it; it's as personal as a Social Security number -- perhaps more so. The spotlights tip a hat to the Media Lab's rakish spirit of cross-pollination, with each spotlight symbolizing a single individual.

Architects are starting to 3D print houses—but without a house-sized printer A couple of months ago, Dutch architect Janjaap Ruijssenaars announced that he was building a curvy, loopy and for some reason, largely see-through building, to be made with the help of Enrico Dini’s D-Shape 3D printer. The project would cost up to 5 million euros ($6.4 million) and be completed in 2014. Janjaap Ruijssenaars’s twisty, loopy 3D-printed building. Universe Architecture Another group quickly piped up, declaring that a similar project they were working on would be done even faster and cheaper. London-based Softkill Design intends to fabricate a web-like building and what’s more, it says it will need just three weeks to print the structure—and only a single day to assemble it, which it plans to do at some point later this year. Softkill Design’s web-like confection of a building. This month, another Dutch company jumped into the fray. DUS Architects plan to use non-traditional 3D printing methods to build a traditional house along a canal in Amsterdam. How it works

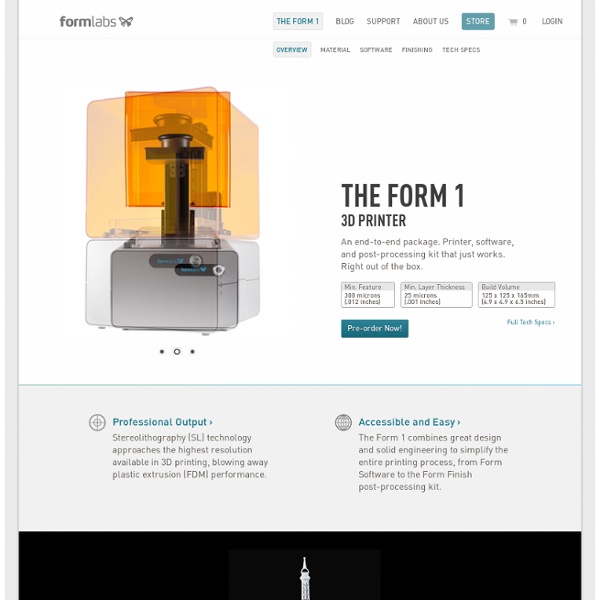

Form 1 - article TechCrunch The Form 1 3D printer, which you may recognize from Kickstarter, has topped $1.4 million in pre-orders in just under a week on the crowd-funding platform. With nearly 1,000 backers already, the FormLabs team has sold out of all their early-bird pledge packages, so anyone who backs the project now is only ahead of the official website sale shipments. Mad Kickstarter success always comes down to demand. Disrupt runner up gTar walked away with 3x its funding goal because it made learning the guitar fun and easy. Pebble took home a whopping $10 million after finding the perfect balance between smart watch functionality, beauty, and battery drain. The Form 1 is no different. There’s a massive gap, and Form 1 aims to fill it. I caught up with co-founder Maxim Lobovsky (once again) to ask about momentum. Lobovsky tells me that FormLabs is being as realistic as possible with quantity.

Replicator Z18 3D Printer 12 months special financing on new MakerBot 3D printer hardware purchases with Dell Preferred Account on Dell.com. Limited-time offer for qualified customers. Offer Details 12 months special financing on new MakerBot 3D printer hardware purchases is a no interest if paid in full by November, 2015 financing promotion. Dell Preferred Account offered to U.S. residents by WebBank, who determines qualifications for and terms of credit. All products in your cart at the time of purchase will qualify for the special financing promotion if purchased with Dell Preferred Account between 11-26-2014 through 12/30/2014. New MakerBot 3D printer hardware purchases are eligible!

Blender Tutorial: Creating a Logo (This tutorial is also available in German and Italian) About Blender Blender is the open source software for 3D modeling, animation, rendering, post-production, interactive creation and playback. You can download Blender free of charge on www.blender.org. Introduction Well, this time things aren’t going to be as exciting as the ride in the mines, but I’m sure I can show you all some very useful Blender techniques. This kind of stuff is actually the kind of work that pays computeranimators. The techniques that you will learn in this tutorial include: Rotoscoping (tracing a background image)Working with curves Tracing your logo Note before you begin: unfortunately as of Blender 2.37 the Background Image that is used below is broken. The most tedious part of creating a logo animation is tracing the logo. In this case, I just ripped a cool looking logo from the internet. Fire up Blender and remove the plane from the middle of the screen. Select a file, and load your logo into Blender.

Form1 - Kickstarter Are you frustrated that low-end 3D printers don’t have the quality to make the true beauty of your designs real? Do you dream of having the power and resolution of a truly professional machine on your desktop? We’ve created an easy-to-use system that rivals the output of high-end printers at a fraction of the cost. Our reason for starting this project is simple: there are no low-cost 3D printers that meet the quality standards of the professional designer. As researchers at the MIT Media Lab, we were lucky to experience the best and most expensive fabrication equipment in the world. But, we became frustrated by the fact that all the professional-quality 3D printers were ridiculously expensive (read: tens of thousands of dollars) and were so complex to use. We’ve been hard at work for over a year, and with your help, we’re ready to take the Form 1 into full-fledged production. We’ve gone to extraordinary lengths to design a complete 3D printing experience: They look like this: Spiffy, eh?

OWL – Old World Labratories » OWL Nano™ Manufactured in Hampton Roads, VA, the OWL Nano™ is constructed from industrial components. It is designed for easy transport with zero disruption to the printer’s resolution. Its size, aesthetics and quiet operation make it appropriate for almost any setting: in an office or lab, on a manufacturing floor or in a home environment. Next-Generation Stereolithography: Stereolithographic printing is the gold standard in 3D printing. Single strand laser beam, virtually no distortion: OWL Nano takes traditional stereolithography to a higher level. Perpendicular printing: The OWL Nano’s laser maintains a perfectly perpendicular position below the object it is forming, which creates a more balanced 3D print.

Fundstück: Mit Physik gegen Knöllchen - Wissen Von klü Strafmandat kassiert? Kein Problem. Man sollte nur Physik können: Ein Physiker in San Diego wurde so ein Knöllchen über 400 Dollar los. Stuttgart - Sicherlich ist Ihnen längst bekannt, dass die Physik ein unersetzlicher Helfer in vielen Fährnissen des Lebens ist. Die dreieinhalb Seiten sind gefüllt mit mathematischen Berechnungen und farbigen Grafiken.