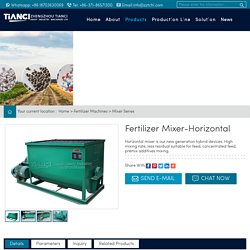

Horizontal Mixer ,Vertical Mixer. Horizontal mixer machine is a kind of fertilizer blending plant, it can mix the material with high uniformity and less residue.

It is very suitable for the animal feed, concentrated feed, additive premix mixture. Mixed with high uniformity, less residue, suitable for more than two kinds of fertilizer, additive premix mixture. The specific features of the horizontal mixer is as bellow 1) The material can be fully mixed, so mixing uniformity is highly improved. 2)The mixer structure is innovative rotor structure , the minimum gap between the rotor and the shell can be adjusted to close to zero, effectively reducing the amount of material residue; Vertical Mixer,Double-shafts Horizontal Mixer. Vertical mixer is a kind of fertilizer mixer which is mainly used for mixing raw materials.

The machine is made of polypropylene plate lining or stainless steel plate, which is not easy to stick and wear resistance. The cycloidal pinwheel reducer has the advantages of compact structure, convenient operation, uniform mixing and convenient unloading and conveying. Mixer Series. Half-wet Material Crusher Machine,Chain Crusher. Brief introduction The series of semi-wet material crusher is a professional one with many years experience and advanced crushing technology at home and abroad by our scientific research personnel.

The machine completely solve the problem of organics crushing with high moisture content, which is a national initiative, and declare the national patent. The successful development of this machine played a key role in cutting down the process of the bio-organic and compost fertilizer, Reduce equipment investment and Saving running cost. NPK and Organic Fertilizer Granulator. Cage Crusher,Chain Crusher. Chain Crusher, Half-wet Crusher Machine. Overview Chain crusher is applied to the shattering of the block in the production of organic fertilizer, Also, it is widely used in chemical industry, building materials, mining and other industries.

This machine use high-intensity wear resisting and cemented carbide chain plate with synchronous speed, and it has reasonable design for entrance and out quarrel, so which results in such advantages: fully broken, difficult to stick wall, easy to clean. The function and structure There are two types structure: one is vertical type with single motor, the other is horizontal type with double motor. Round Polishing Machine. The organic fertilizer round polishing machine designed on the basis of flat die extrusion granulator machine.

Polish the cylindrical pellets made by flat die extrusion granulator machine to ball shape granules one time; No need polish again; Ball forming rate is very high≥ 97%; Granules with high density,beautiful and practical.Is the ideal equipment to produce organic (biological) fertilizer granulator. This machine designed with special internal structure according to the process requirements, is an effective compound-organic fertilizer dedicated machine. Organic Fertilizer Round Polishing Machine Features: Ring-die Granulator. This machine is one of the main (biological) organic fertilizer production equipment produced by our company.

It is the fertilizer machinery which has been studied, improved and carefully manufactured on the basis of advanced granulating machine at home and abroad. The machine is excellent in technology and simple in operation, and is designed with different models and various models. It is an ideal processing machine for the fertilizer processing. Features: 1.The machine is mainly used for pellet processing of (bio) organic fertilizer, compound fertilizer and aquaculture processing industry. 2.The granular material processed by this machine has a smooth surface, moderate hardness, low temperature rise in the processing process and can keep the nutrients inside the raw material better.

The mixer and the granulation machine are three in one. Flat-die Press Fertilizer Pellet Mill - Tianci. Multifunctional organic fertilizer granulation machine is the latest technology granulator machine.

It is designed by the Agricultural Machinery Research Institute with many years productions experience on the fertilizer making process equipment. It has won state utility model patents. It is used for granulation of various organic substances after fermentation, breaking the conventional organic fertilizer making process, without drying, crushing and granulating the raw materials before pelletizing, and processing the spherical granules with direct ingredients, thus saving a large amount of energy. The Structure principle. New Type Stirring Tooth-Drum Granulator. Stirring tooth-drum granulator is a new patented product developed by our company and the Agricultural Machinery Research Institute.

It is designed and manufactured by the new technology of wet continuous push rod granulation. The machine can not only granulate a variety of organic matter, especially for the coarse fiber materials which are difficult to be granulated by conventional equipment, such as crop straw, wine residue, mushroom residue, drug residue, animal dung and so on. Roller Press Granulator. Description of Double Roller Granulator: Double roller press granulator, belong to the extrusion slip model, its working principle is: the motor drive the belt and pulley, transfer to the drive shaft through the speed reducer, through the open gear synchronously with the driven shaft, the double rollers rotate in the opposite direction.

The raw material input through the feed hopper, and after the extrusion molding, demoulding granulating, through a chain transfer to crushing and screening, after separating , the finished granules come out, and the powder will be back to the mixer, for granulation again. With the continuous rotation of the motor, the continuous input of material, to achieve mass production. Features of Double Roller Granulator:1.The roller press granulator is without drying process, room temperature granulation, a molding , less investment, quick effect, good economic returns. 2. Rotary Drum Granulator - fertilizer granulation machine. Rotary drum granulator is a kind of fertilizer granulator machine can make the material into a specific shape.

Drum granulator is one of the key equipment of the compound fertilizer industry. It is suitable for large-scale production of cold &hot fertilizer granulation line and high and low concentration compound fertilizer line. Main work method for aggregate wet granulation, through a certain amount of water or steam, the basis for fertilizers in the cylinder body after full wet chemical reaction, in a certain liquid under the conditions of the rotating cylinder with campaign, reunion between particles to produce extrusion pressure of material into a ball. New Type Organic Fertilizer Granulator. 1. Product Overview This fertilizer granulator series is a new patented product researched and developed by our company and the Agricultural Machinery Research Institute, which adopts new design and manufacturing technology : wet continuous push rod granulation.It has obtained the state practical patent.

It is used for granulation for all kinds of organic matter after fermentation, crushing through the conventional organic prilling before granulating need not to dry and crush the raw materials. It can direct burdening to work out round pellets, can save a lot of energy. Disc Granulator for Fertilizer Production. The series of disc granulator is a new kind of slanting disc granulation equipment: the granulation rate is more than 90%, the reducer and the motor adopt the flexible belt drive, start smoothly, reduce the impact force and improve the service life of equipment. The plate bottom of the granulator is reinforced by a plurality of radiation steel plates, which is firm and durable, never deformed, thickened ,aggravated, and stable base design don’t need the anchor bolts fixed and operates stably.

The granulator main gear adopts High frequency sudden fire, have doubled service life. Crusher Series. Fertilizer Granulator Series. Organic fertilizer manufacturing equipment. Organic fertilizer manufacturing equipment uses pig manure, cow manure, chicken manure and other livestock manure as raw materials to produce organic fertilizer. When chickens, pigs, sheep and other poultry and livestock feed their feed, because of their weak digestion ability, 75% of the nutrients in the feed are discharged with the feces, and the discharged feces contain nitrogen, phosphorus, potassium, organic matter, amino acids, and protein. Such as organic matter that is good for soil and crops, so many people use organic fertilizer equipment to make these manures into organic fertilizer for secondary use. Advantages of organic fertilizer manufacturing equipment: Operation method of organic fertilizer semi-wet material pulverizer.

Operation method of semi-wet material crusher for organic fertilizer production line equipment: The organic fertilizer semi-wet material grinder is a kind of equipments required for biofertilizer production. This equipment has a very good use effect. NPK Fertilizer Production Line and Organic Fertilizer Production Line Supplier. How to Choose and Purchase Biofertilizer Production Equipment.

1. Determine the type of fertilizer produced. There are four types of organic fertilizer, pure organic fertilizer, organic-inorganic compound fertilizer, bio-organic fertilizer and compound microbial fertilizer. New Type Stirring Tooth-drum Granulation Production Line. NPK Fertilizer Production Line,NPK Fertilizer Production.