Otomotiv kısaltmaları. SECUduino. VSS or Vehicle Speed sensor. Fuel Tank Level Sensor. Controller area network. CAN bus (for controller area network) is a vehicle bus standard designed to allow microcontrollers and devices to communicate with each other within a vehicle without a host computer.

CAN bus is a message-based protocol, designed specifically for automotive applications but now also used in other areas such as aerospace, maritime, industrial automation and medical equipment. Development of the CAN bus started originally in 1983 at Robert Bosch GmbH.[1] The protocol was officially released in 1986 at the Society of Automotive Engineers (SAE) congress in Detroit, Michigan. The first CAN controller chips, produced by Intel and Philips, came on the market in 1987.

Bosch published the CAN 2.0 specification in 1991. Controller area network. CAN (Controller Area Network), CANopen’ın fiziksel katmanını oluşturan ve otomotiv otomasyonunda kullanılmak üzere Bosch firması tarafından geliştirilen bir seri ağ teknolojisidir.

Özellikle Avrupa’da üretilen arabalar için geliştirilmişse de, endüstriyel otomasyonda ve diğer pek çok sektörde tutulan bir ağ olmuştur. İletişim, değişik elektronik modüller arasında elektriksel gürültülerden dolayı oluşabilecek hatalardan etkilenmeyecek CAN-Hi ve CAN-Lo olmak üzere iki ayrı kablo ve çok güvenli bir protokol sayesinde sağlanır. Ayrıca bu şebekenin bir özelliği de modern otomotiv sistemlerinde hayati önem taşıyan hava yastığı, fren, ABS gibi yolcu güvenliğini ilgilendiren modüllere önem sırasına göre bağlantı önceliği tanımasıdır. CAN, çift burulmuş kablolu, half duplex, yüksek hızlı bir ağ sistemidir. Mikrodenetleyiciler arasında gerçek zamanlı iletişim de dahil pek çok ihtiyaca cevap verir. CAN-Bus - Vikisözlük. Vikisözlük sitesinden Kısaltma[değiştir] Anlamlar.

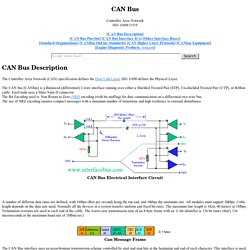

CAN Wiki - all to need to know. Introduction to CAN Bus Technology. Microcontroller.com. CAN Bus Interface Description CANbus Pin Out, and Signal Names. Controller Area Network. Controller Area Network ISO 11898/11519 [CAN Bus Description] [CAN Bus Pin-Out] [CAN Bus Interface ICs] [Other Interface Buses] [Standard Organizations] [CANBus OnLine Standards] [CAN Higher Layer Protocols] [CANbus Equipment] [Engine Diagnostic Products, Amazon] CAN Bus Description The Controller Area Network (CAN) specification defines the Data Link Layer, ISO 11898 defines the Physical Layer.

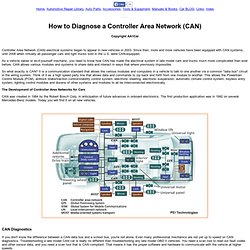

The CAN bus [CANbus] is a Balanced (differential) 2-wire interface running over either a Shielded Twisted Pair (STP), Un-shielded Twisted Pair (UTP), or Ribbon cable. Each node uses a Male 9-pin D connector. CAN Bus Electrical Interface Circuit A number of different data rates are defined, with 1Mbps (Bits per second) being the top end, and 10kbps the minimum rate. Can Message Frame The CAN Bus interface uses an asynchronous transmission scheme controlled by start and stop bits at the beginning and end of each character. {Industrial CANbus Index} Automotive CAN Network Diagnostics. Home, Automotive Repair Library, Auto Parts, Accessories, Tools & Equipment, Manuals & Books, Car BLOG, Links, Index Copyright AA1Car Controller Area Network (CAN) electrical systems began to appear in new vehicles in 2003.

Since then, more and more vehicles have been equipped with CAN systems, until 2008 when virtually all passenger cars and light trucks sold in the U.S. were CAN-equipped. As a vehicle owner or do-it-yourself mechanic, you need to know how CAN has made the electrical system in late model cars and trucks much more complicated than ever before. CAN allows various modules and systems to share data and interact in ways that where previously impossible.

CAN in Automation (CiA): CAN. CAN in Automation (CiA): CAN. CANbus USA - also known as CAN bus or Controller Area Network. Přehled CAN sběrnice. Přehled aplikací se sběrnicí CAN Řízení vzdálených zařízení (zadání požadavků řízení, konfigurace parametrů, diagnostika) Předávání informací v technologii (vzdálená čidla, akční členy, operátorské panely) Průmyslové informační systémy (rychlá komunikace mezi množstvím jednotek informačního systému) Systémy inteligentních budov (zabezpečovací systémy, řídící systémy) Přehled výhod a nevýhod sběrnice CAN Pro rychlý obraz o výhodách sběrnice CAN lze uvést tyto výhody a nevýhody: Výhody Vysoká rychlost přenosu dat až 1Mbit/s při délce sběrnice do 40m (500kbit/s – 130m, 125kbit/s – 560m) Rozlišení zpráv identifikátorem CAN 2.0A 11bitů a CAN 2.0B 29bitů Selekce přijímaných zpráv na základě jejich identifikátoru Prioritní přístup zabezpečující urychlené doručení významných zpráv Diagnostika sběrnice např.: chyba doručení zprávy, chyba CRC, přetečení bufferu Značná úroveň zabezpečení přenosu Vysoká provozní spolehlivost Stále se rozšiřující součástková základna Nízká cena Nevýhody.

The Virtual Vehicle: Part 1 - In-vehicle networking simulation and analysis.