Digital Designs for 3D Printing - by Dizingof - 3Dizingof.com. Bits and Parts. BITS & PARTS - Makerchairs Bits & Parts aims to utilize small 3dprinters and cnc milling machines to fabricate full size affordable furniture available to all.

By fractioning designs into many small parts we where able to radically expand the potential of small consumer 3d printers and cnc milling machines. The 3D parts can be assembled into a piece of furniture like a 3 dimensional puzzle. The first prototype was created with the help of a 3d printing hub to create the worlds first "crowd fabricated" chair. The first chair is generated out of a single shape divided into 202 3d jigsaw puzzle parts. Bits & Parts is a work in progress project and we invite all makers around the world to help improve the designs creating the most efficient, beautiful, comfortable, fully recyclable furniture in the world that can be produced locally.

RecycleBot v2.3 Controls by jpearce. The mechanical design is equivalent to RecycleBot v.2.2 - I strongly recommend reading that first.

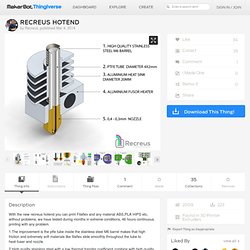

This design is, of course, far from optimized particularly with respect to cost and DYI, it is primarily being used by the Michigan Tech in Open Sustainability Technology Research Group to make new fucntionalized 3-D printing materials (e.g. electrically conductive) to support a full range of products open-source disributed manufacturing...lots more to come. Some of the improved features over RecycleBot v2.2 are: 1. Type of plastic can be selected from the keypad interface and the controller automatically updates the extrusion temperature for the plastic. 2. Extrusion temperature can also be feed by the keypad interface for any type of plastic which can be melted and extruded. 3. Dirk Vander Kooij. 4Track by Kepler. 3D auf Pinterest. RECREUS HOTEND by Recreus. With the new recreus hotend you can print Filaflex and any material ABS,PLA HIPS etc, without problems, we have tested during months in extreme conditions, 46 hours continuous printing with any problem. 1.The improvement is the ptfe tube inside the stainless steel M6 barrel makes that high friction and extremely soft materials like filaflex slide smoothly throughout the tube to heat-fuser and nozzle. 2.High quality stainless steel with a low thermal transfer coefficient combine with high quality aluminiun heat sink with high thermal transfer coefficient creates a very cool HOTEND, we insert directly (always with a fan) in direct drive abs part.

KvR's Compact Extruder with Direct Drive by Printing-3D. QU-BD Extruder Modifications by bdring. Adjustable Replicator Drive Block by CreativeTools. Spring-loaded Replicator 2 Drive Block by MakerBot. Direct-drive hinged extruder for E3D/J-Head hot-end (Prusa i3) by ffleurey. Here is my attempt at designing an extruder for my Prusa i3.

I took some inspiration from different designs to try to make an extruder which is easy to print, compact, easy to clean and has tight guides for the filament (to be able to use flexible materials). I made a couple of test prints with it and it seems to work fine so far. I haven't tested any challenging materials yet, just PLA. Very smal E3D mount (J-head mount?) for the Ultimaker by MoonCactus. About satoer. E3D hotend easy maintenance carriage for Felix 3D printer by satoer Oct 1, 2013 Bowden tube feeder with filament release mechanism by satoer Oct 1, 2013 Windmill coat hanger with mechanics by satoer Mar 26, 2013 Friendly mousetrap, fully printable by satoer Jan 25, 2013 Duplo hexagon railroad crossing by satoer Dec 28, 2012 Microphone shock mount for camera by satoer Dec 1, 2012.

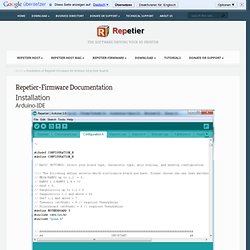

Repetier Was muss ich einstellen. Installation der Repetier-Firmware für Arduino Boards 3D-Drucker. Arduino-IDE First you need to get and install the development software.

Don‘t worry, it is easy and you won‘t need special programming skills. Get your version of the Arduino IDE from . The software is available for WIndows, Linux and Mac. Follow the instruction on the Arduino site. The IDE contains only the officially supported board driver. The next step is driver installation. To understand the IDE, you should now download the latest version of Repetier-Firmware.

It is not necessary to clone the repository. Before you can compile and upload the firmware, you need to select the board and port. For a first successful upload, follow the next steps: Open the register tab named „Configuration.h“Search the line „#define MOTHERBOARD“ and change the number behind to match your board.Near the bottom you see a line „#define BAUDRATE 250000“. Congratulations! Common errors General configuration. Variable holder for optical z-endstops for Prusas Mendel by Ablapo.

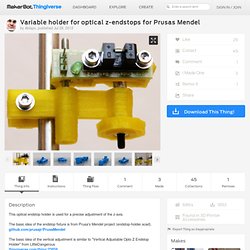

Printing ======== Adjust the size parameters in the scad file for your printer and print it.

Or you can just use those uploaded files for printing: 1 x VzE_wheelV2.stl, 1 x VzE_holderV2.stl, 1 x VzE_endstopV2.stl Essential "hardware" ==================== 1 x springs 5.4 mm x 17.5 mm 7 x M3 nuts 1 x 35 mm M3 HexBolt (total threaded) 1 x 40 mm M3 HexBolt (half threaded, half smooth) 1 x 20 mm M3 HexBolt 2 x 15 mm M3 HexBolts 5 x M3 washers Let's built it! =============== Take the 40 mm HexBolt and decapitate the bolt's head - not your finger! There are several ways how to assemble it, but lets describe my way. GRRF DD Extruder Upgrade für by Mexx.