Woltersmotorsusa

Wolters Motors. Electric pump motors and close-coupled pump motors are designed to meet the specific requirements of centrifugal pumps where the pump impeller is mounted directly on the motor shaft.

Shaft types include JM, JP, and West Coast styles. These electric pump motors are available in both EPAct and NEMA Premium efficiencies. Vertical Hollow Shaft motors are designed for use on turbine, mix flow, and propeller pumps. They feature a P-Base style mount where the line shaft goes up through the motor and out the top where it is secured. Vertical Hollow Shaft Motors are available in Totally Enclosed Fan Cooled and Weatherproof I enclosures with normal, high, and extra-high thrust capabilities. Vertical Solid Shaft motors feature a P-base mount for vertical mounting on in-line pump applications. Some of the most popular brands carried by Wolters Motors & Drives include: ABB/Baldor. Explosion Proof Motors. To be classified as explosion proof, the motors must be manufactured to the requirements of Underwriters Laboratories (UL) and the National Electrical Code (NEC) in class, group, and temperature code restrictions.

Explosion proof motors are designed for use in hazardous environments having certain explosive gases or materials present, like those found in the chemical, coal mining, textile, and petrochemical industries. It is important to select an explosion proof motor that is approved for use in the specific class and group that defines the hazardous environment the motor will run in. Understanding What Can Cause an Explosion Before investing in an explosion proof motor from Wolters Motors & Drives, it’s important to understand what can cause an explosion in a motor in the first place. There are two common scenarios that can lead to such an incident, they are: Aegis Bearing Protection Ring.

With the use of AC and DC motors, variable frequency drives often induce damaging electrical voltages on the motor shaft.

Bearing lubricant can only do so much to prevent harm, and fluting damage, fusion craters, and severe pitting can result. These lead to bearing failure, but motors with AEGIS® rings installed allow , you to avoid this frustration. An AC or DC motor with an AEGIS® bearing protection ring will work safely by diverting the damaging shaft voltages and bearing currents to the ground, in turn extending the lifetime of your motor.

Why Choose AEGIS® Bearing Protection Rings & Motors Over Competitors? When selecting the best bearing protection rings on the market, technicians would be hard-pressed to find a better manufacturer than AEGIS®. The unique technology from AEGIS® protects bearings by combining nanogap technology to help shield them from electric charges that frequently cause frosting, fluting, and pitting damage. Satisfaction Guaranteed. Baldor &LeesonLarge AC Motors. Perhaps Wolters Motors’ most prominent supplier is Baldor Electric Company, a leading manufacturer of energy-efficient large AC electric motors that has recently announced a new product line: the Large AC – GPM Induction motors.

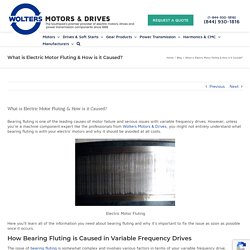

Wolters is proud to make these large AC motors available to customers across the U.S., improving performance in numerous high-torque applications that include fans, compressors, mills, and conveyors. Baldor Electric Motors The Large AC – GPM motors are available in stock ratings 250 – 1000 HP and 2300/4000 Volt. What is Electric Motor Fluting & How is it Caused? Bearing fluting is one of the leading causes of motor failure and serious issues with variable frequency drives.

However, unless you’re a machine component expert like the professionals from Wolters Motors & Drives, you might not entirely understand what bearing fluting is with your electric motors and why it should be avoided at all costs. Electric Motor Fluting Here you’ll learn all of the information you need about bearing fluting and why it’s important to fix the issue as soon as possible once it occurs. How Bearing Fluting is Caused in Variable Frequency Drives The issue of bearing fluting is somewhat complex and involves various factors in terms of your variable frequency drive. However, it’s this fast type of switching back and forth that creates an undue strain on the variable frequency drive’s motor shaft, forcing the need for insulated bearings. What Are Some Signs of Bearing Damage? How Do I Protect Against Bearing Fluting? Contact us for more ways to avoid bearing fluting. Aegis Bearing Protection Ring. Gear Motor Products & Gear Reducers. Wolters Motors & Drives is a leading provider of turnkey sourcing solutions for gear motor products and gear reducers for electric motors.

We specialize in procurement services for motor shops, facilities maintenance departments, OEMs, and industry in the Southeast. With over 50 years in the industry, we have the experience and application knowledge to source the best gear motor products for your specific requirements. We sell you the gear products you need, when you need them, at the best price. We provide a full line of gear products and reducers for electric motors from the industry’s leading manufacturers. Gear MotorsWorm Gear ReducersHelical Inline Gear ReducersHelical-Bevel Gear ReducersParallel Shaft Gear Reducers Our warehouse in Duluth, GA stocks a full inventory, and if we do not have the gear product you need in stock, our online ordering systems allow for fast delivery from the manufacturer.

We Carry Today’s Leading Brands of Gear Motor Products. Wolters Motors & Drives. Wolters Motors & Drives. Close-Coupled Pump Motors. Wolters Motors & Drives. Crusher Duty motors, also commonly called Quarry Duty, are designed specifically for quarry and mine use.

To meet these very strenuous demands, a crusher duty motor will have oversized bearings and shafts, high strength shafts, exceptional high torque, larger frames, and roller bearings for heavy radial loads associated with belt-driven applications. Crusher duty motors are not typically found in direct coupled applications. Our inventory of crusher duty motors is expansive. We carry today’s leading brands for a variety of heavy-duty applications, including: ABB/Baldor Crusher Duty Motors: Designed for belt-driven rock crushers, the crusher duty motors manufactured by ABB/Baldor offer high starting toques for heavy-duty applications.

Contact a Wolters representative today and request a quote. Compressor Duty Motors. Wolters Motors & Drives. Keeping engines maintained and in good condition is challenging in any industrial situation – but few industries are more rigorous than that of food and beverage production.

Tightly regulated, these operations are held to far higher standards of cleanliness and sanitation. This is entirely reasonable, given the dangers of food contamination, but it creates a significant challenge for those designing and maintaining such facilities – how do you maintain industrial processes when the engines involved must be regularly washed, sanitized, and even subjected to caustic chemicals? The solution comes from washdown motors. How Washdown Motors Improve Food and Beverage Production Washdown motors are specifically designed to withstand high-pressure water cleaning, caustic decontamination agents, and potentially even complete water submersion – without breaking down or having electrical issues. These motors are a necessity in any sort of food or beverage processing plant. Baldor Large AC Motors. Gear Motor Products & Gear Reducers. Compressor Duty Motors. Washdown Motors from Wolters Motors & Drives. Find Wholesale Electric Motors from Wolters Motors & Drives.

Severe Duty Motors. Inverter Duty Motor.