Non Woven Medical Tapes Manufacturer. Our tapes are manufactured with a range of materials that are suitable for different environments and applications.

Polyimide Tape – is extremely strong and heat resistant. It is used to bond silicone and other difficult surfaces. Polyurethane tapes are extremely durable and are used to protect surfaces. Foil Tapes – are used to damp vibration and mask surfaces during paint stripping. Glass Cloth Tape – Used primarily in aerospace applications, it is extremely flame retardant, solvent resistant, and used to protect heat-sensitive devices in areas exposed to high temperatures. Medical Conductive Adhesives & RFI Shielding. Structural Ceramic Heaters. Ceramic parts are made from inorganic, non-metallic materials and provide high functionality for components in equipment and devices with diverse functions.

With their crystalline, partly crystalline, and amorphous glass structure, engineered ceramics have solved numerus problems in electrical, chemical, and mechanical applications. The high heat resistance of ceramics enables them function when metal and polymers are unsuitable. Medical Conductive Adhesives & RFI Shielding. Medical Conductive Adhesives & RFI Shielding. Manufacturing Capabilities - Fralock Development Site.

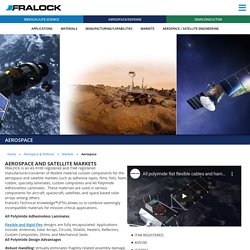

Custom Aerospace Components: Designed for Utility Article - ArticleTed - News and Articles. Aerospace projects, aircraft, or satellites need specially manufactured components that have special features to suit temperature, pressure and thermal extremes faced by aircraft.

Not only in aircraft, but in the case of any electro-mechanical machinery, it is extremely important to choose the right material. Electrical Insulation Film Electrical Insulation Film can be made of various materials. Proper Electrical Insulating Material - Fralock White Paper. Corporate Headquarters|28525 W. Industry Drive|ValenciaCA91355|Toll-free: 800.372.5625|Local: 661.702.6999 © 2021 Fralock Innovative Materials Manufacturing & Automation Cirlex® and Kapton® are registered trademarks of affiliates of DuPont de Nemours, Inc. used under license by Fralock.

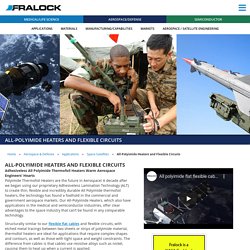

Read our Privacy Policy. Fralock does not collect personally identifiable information about individuals except when such individuals voluntarily provide such information. Polyimide Thermofoil Heaters. Polyimide Thermofoil Heaters are the future in Aerospace!

A decade after we began using our proprietary Adhesiveless Lamination Technology (ALT) to create thin, flexible and incredibly durable All Polyimide thermofoil heaters, the technology has found a foothold in the commercial and government aerospace markets. Our All-Polyimide Heaters, which also have applications in the medical and semiconductor industries, offer clear advantages to the space industry that can’t be found in any comparable technology. Structurally similar to our flexible flat cables and flexible circuits, with etched metal tracings between two sheets or strips of polyimide material, thermofoil heaters are ideal for applications that require complex shapes and contours, as well as those with tight space and weight constraints. Semiconductor CNC Machining - Fralock. Fralock can provide custom CNC machining services that include CNC Cutting, drilling, punching, knife cutting, and CNC routing.

On Prototype runs we can offer quick turn-around, tight tolerances, with production like quality! Let Fralock accommodate all of your CNC machine service needs. CNC machines offer many benefits over manual machines of the same type. Satellite Markets-All Polyimide Adhesiveless Laminates- Custom Satellite Aerospace Engineering. FRALOCK is an AS-9100 registered and ITAR registered manufacturer/converter of flexible material custom components for the aerospace and satellite markets such as adhesive tapes, films, foils, foam, rubber, specialty laminates, custom composites and All Polyimide Adhesiveless Laminates.

These materials are used in various components for aircraft, spacecraft, satellites, and space based solar arrays among others. Fralock’s Technical Knowledge™ (FTK) allows us to combine seemingly incompatible materials for mission-critical applications. All Polyimide Adhesiveless Laminates. Aerospace Electrical Insulation Supplier. Cirlex® Polyimide - Polyimide Film Manufacturers. Broaden your application horizons … DuPontTM CIRLEX® polyimide maintains all the excellent performance characteristics – electrical, physical and chemical – of DuPont™ KAPTON® Available in thicknesses starting at 8 mil (.008”,.20mm) Improved yields from large and custom sheet sizes Ideal match for environmental extremes UL® 94VO rated.

Aerospace Electrical Insulation Supplier. Polyimide Thermofoil Heaters: Durability and Resistance Article - ArticleTed - News and Articles. Thermofoil Heaters are heaters with thin and flexible components.

They have an etched-foil resistive heating component covered between layers of flexible insulation. They came into operation 45 years ago. Since then, these heaters have been widely used due to their convenience and advantage over traditional electric heaters. Semiconductor Laser Cutting - Fralock. Laser Cutting Service A Synthesis of Power and Precision: An economic advantage.

Laser cutting is an advantageous technology choice. Fralock’ s careful evaluation of the features of the most suitable laser cutting service system guarantees optimum results in the following aspects: reduction of total work times; increase in production quality. The technological advantage Laser cutting services are, above all, precise, clean, and silent. Aerospace Electrical Insulation Supplier. Cirlex® Polyimide - Polyimide Film Manufacturers.

Medical Adhesive Technologies. Selecting the proper medical adhesives for any application must include consideration of the substrate surface characteristics and the application performance requirements.

Fralock is an industry leader in providing adhesive technologies solutions utilizing over thirty years of experience in providing solutions with Pressure Sensitive Adhesives (PSAs), hot melts, B-Stage, and some liquid adhesives as well. Medical Adhesives technology has made advancements over the past decades and pressure sensitive adhesives (PSAs) have become accepted in many applications over liquid adhesives or mechanical fasteners.

Fralock has been incorporating pressure sensitive adhesive technology in a variety of products and applications including printer cartridges, hard disks, computers/peripherals, medical devices and equipment, and countless others. Semiconductor CNC Machining - Fralock. Custom Aerospace Adhesive Coating. When an off-the-shelf product will not meet your adhesive technology needs, it is time to look into customized solutions. Fralock has over 50 years of proven history in developing specialty and custom adhesives and composite materials for your unique applications. The days of simply applying a “standard” adhesive are over. We, at Fralock, understand that the demands of the marketplace are extending beyond the substrate and into adhesive coating technologies.

We can help you match your application to a proper adhesive coating for maximum performance. Non Woven Medical Tape. Medical tape is used for a variety of reasons in a healthcare setting, such as securing dressings, wound care products or medical devices, like catheters, to a patient. Medical tapes are made from different materials, and have varied levels of adhesive backings, depending on the tape’s purpose. Wound care tape is generally moisture proof, and it may contain a zinc oxide adhesive. General-use tape offers less adhesion for easier tape removal. Nonwoven materials are increasingly popular in medical applications because they are:

Aerospace/Defence Market – Custom Aerospace Components. FRALOCK is an AS-9100 registered and ITAR registered manufacturer/converter of flexible materials such as adhesive tapes, films, foils, foam, rubber, specialty laminates, and custom composites in the Aerospace market. These materials are used in various components for aircraft, spacecraft, satellites, and space based solar arrays among others. Fralock’s Technical Knowledge™ (FTK) allows us to combine seemingly incompatible materials for mission-critical applications. All Polyimide Adhesiveless Laminates Flexible and Rigid-Flex designs are fully encapsulated. All Polyimide Flex Circuits. Custom Aerospace Adhesive Coating. Aerospace/Defence Market – Custom Aerospace Components. Custom Aerospace Components. Power Distribution Cable: The Lifeline of Power Transmission. Fralock has served the aerospace industry for over 50 years. From humble beginnings as a specialty tape distributor to a manufacturer of custom aerospace components and subassemblies, the company now provides a full range of design, development, and manufacturing services to meet the needs of OEM’s serving the satellite industry.

As application demands increase for polymer based solutions, Fralock is able to meet those needs by developing and manufacturing special purpose polymers, foils and adhesive based products and components for technically advanced OEM’s. Fralock’s high performance material combines heat resistance, dimensional stability, and chemical resistance, to be used in hostile and extreme environmental conditions. Unlike most plastics, it does not produce significant outgassing even at high temperatures. It also performs well in vacuum applications, down to extremely low cryogenic temperatures. Custom Prototype. Gasket Manufacturer.