A 3-D Printed House?

Well, this may well be the coolest video you see today. It’s a TEDx talk from a fellow named Behrokh Khoshnevis, who is a professor of engineering at USC, where he directs something called the Center for Rapid Automated Fabrication Technologies. CRAFT has stated as its grand challenge “building a custom-designed house in a day while drastically reducing the costs, injuries, waste and environmental impact associated with traditional construction techniques.” The applications of such rapid-fire housing are endless: affordable housing for the poor; “extraterrestrial buildings constructed from in situ materials”; emergency FEMA-style housing, and the like. But don’t listen to me–listen to the guy who’s trying to make it a reality. And if you’re really pressed for time, let me call out some of the most exciting things the professor says here, with a few little glosses of my own. “In the end the whole building can be ready in an unprecedented time. Bur wait? What do you think?

Domerama

Nature of science

3D Printing: The Greener Choice

Newswise — 3D printing isn’t just cheaper, it’s also greener, says Michigan Technological University’s Joshua Pearce. Even Pearce, an aficionado of the make-it-yourself-and-save technology, was surprised at his study’s results. It showed that making stuff on a 3D printer uses less energy—and therefore releases less carbon dioxide—than producing it en masse in a factory and shipping it to a warehouse. Most 3D printers for home use, like the RepRap used in this study, are about the size of microwave ovens. They work by melting filament, usually plastic, and depositing it layer by layer in a specific pattern. Common sense would suggest that mass-producing plastic widgets would take less energy per unit than making them one at a time on a 3D printer. They conducted life cycle impact analyses on three products: an orange juicer, a children’s building block and a waterspout. Some of the savings come from using less raw material. Comment/Share

WASP's Revolutionary Delta Printer 3D Prints Structurally Sound Homes from Clay

Italy’s WASP (World’s Advanced Saving Project) aims to help the world’s impoverished by 3D-printing sustainable dwellings using all natural materials. Unveiled at the Maker Faire Rome, the portable 3D printer called the Delta can be transported to areas in need to print homes on site. The printer works with locally-sourced materials like mud and fiber to create structurally sound homes with a culturally-sensitive, vernacular aesthetic. Unlike other 3D printing companies, WASP has turned its attention to natural and local materials, rather than quick printing plastics, to create healthy new homes. Related: The World’s First 3D Printed Room is a Mind-Boggling Baroque Interior Inspired by the long tradition of building homes from clay, mud and fibers in Morocco, the Delta takes the labor out of the building process to create needed shelters in a snap. Via Phys.org

An Afternoon with the Handibot

I’ve never been much of a woodworker. While I can design and plan woodworking projects, the finesse that woodworkers have with wood always amazes me. That’s why CNC machines have always fascinated me. A few years ago I even built my own. I would love to have a full size CNC machine, but for me as a tinkerer, it’s cost and space prohibitive. The Handibot is a portable CNC machine that you can carry around and drop on top of the work piece that you want to cut. I’ve had a lot of fun cutting out all kinds of widgets with it in the few months that I’ve had it. First, I needed something to cut. Next, I had to prepare the files. To prepare files for cutting, you need to setup tool paths. This is my parts layout, you can see that this is a toolpath for a larger CNC machine, but since it’s divided into tiles I can cut one of them at a time, working my way over the workpiece. But not before I swung over to Home Depot for some plywood! Here I am working my way down the first set of tiles.

Error and the Nature of Science

March 2004 How science works is the key to understanding its concepts. Einstein predicted in 1907 that light bends in a gravitational field. Today, telescopes on Earth can pick up the light bending around a massive object in space. Scientific information abounds. Profiling the Nature of Science Observation comes from different angles. What features of the nature of the science are most important to know? Scientists think critically about claims. Scientists back their findings with multiple lines of evidence. Observation is sometimes enhanced by quantitative measurement, by comparison—especially with controls that isolate the effect of individual variables or help distinguish correlation from causation—and by graphical representation and statistical analysis summarizing patterns in the data and the chances for error.Data does not speak for itself. Science deals with facts, not values. Science is a human enterprise. Some claims are rooted in unsound principles. Tentativeness and Error Material

The world’s largest Delta 3D printer can print nearly zero-cost housing out of mud

The future of affordable (and sustainable) housing may lie with 3D printing. The World’s Advanced Saving Project (WASP) has unveiled the world’s largest delta-style 3D printer, which can build full-size buildings out of mud and clay for nearly zero cost. The massive BigDelta printer stands 12 meters tall (40 feet), and it's nearly completed its first house at a cost of just 48 euros so far. Italian innovator Massimo Moretti launched WASP with the goal to “create a means for affordable fabrication of homes, and provide these means to the locals in poverty stricken areas.” Related: Need a home? WASP has come an impressively long way in a short span of time, especially considering that the company doesn’t receive any public financing. According to Moretti, “When the work starts again, we will raise the wall until 4 meters, then we’ll create the door and build the roof. Their timing is also advantageous. + World’s Advanced Saving Project Save

I Wood

Kids who spot bullshit, and the adults who get upset about it

Ben Goldacre, The Guardian, Saturday 28 May 2011 If you can tear yourself away from Ryan Giggs’ penis for just one moment, I have a different censorship story. Brain Gym is a schools program I’ve been writing on since 2003. This week I got an email from a science teacher about a 13 year old pupil. Now, this is weakminded, and perhaps even vicious. Emily Rosa is the youngest person ever to have published a scientific paper in JAMA, one of the most influential medical journals in the world. For her school science fair project, Rosa conceived and executed an experiment to test if they really could detect this “field”. 21 experienced practitioners put their palms on a table, behind a screen. Therapeutic Touch practitioners, including some in university posts, were deeply unhappy: they insisted loudly that JAMA was wrong to publish the study. Closer to home is Rhys Morgan, a schoolboy with Crohns Disease. But even before that happens, we can feel optimistic. So the future is bright.

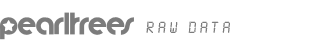

This 3D Printer Can Build 10 Houses A Day For $5,000 Each

Thank you for subscribing! For $5,000 and ten hours you can now buy a 3D printed house. “The days of lengthy, inefficient, and costly construction projects could be coming to an end. “Not only is the printer environmentally ideal but it potentially has the ability to produce sound low cost housing for poverty stricken communities. Learn more here

CLICK-RAFT

Why is science important? - A collection of thoughts from leading scientists, public figures, ...and you.