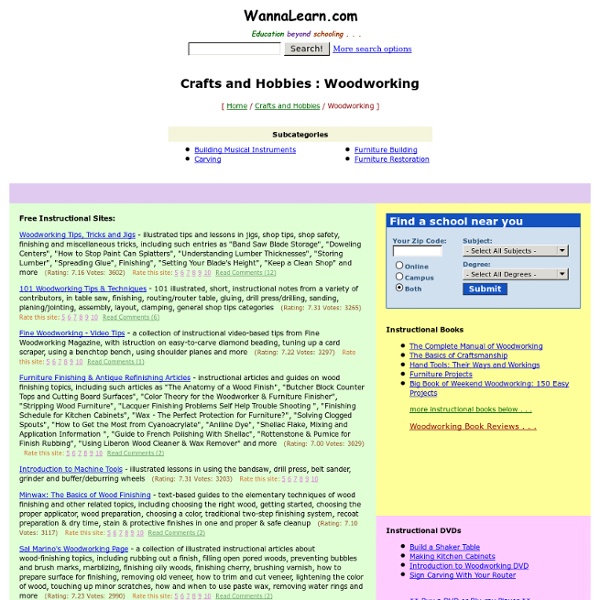

Complete Guide to Woodworking Alabama Woodturners Association Contact: Nelson Brooks Phone: 205-988-3530 Web site: www.alabamawoodturners.com Alabama Woodworkers Guild PO Box 26665 Birmingham, AL 35260 Email: WebMaster@AlabamaWoodworkersGuild.Org Web site: www.AlabamaWoodworkersGuild.Org Last Frontier Woodcarvers 22441 Glacier View Drive Eagle River, AK 99577 Email: Walter_Jr@Jones-Clan.com Alaska Creative Woodworkers AssociationPO Box 201796 Anchorage, AK 99520-1796 Contact: Tom Gamble Phone: 907-243-6369 Arizona Association of Fine Woodworkers Box 44264 Phoenix, AZ 85064-4264 Email: bsaagmillwork@earthlink.net Web site: www.azfinewoodworkers.org Desert WoodcraftersTucson, AZ 85742 Contact: Alan Crosby Phone: 520-744-4973 Email: President@desertwoodcrafters.org Web site: www.desertwoodcrafters.org Woodworkers Association of Arkansas 4 Petress Court Little Rock, AR 72211 Web site: www.woodworkersofarkansas.org Bay Area Woodturners AssociationSenior Center in San Ramon Web site: www.bayareawoodturners.org St. St. St.

WoodBin A Guide to Honing and Sharpening Woodworking Tools One of the most important skills a woodworker can acquire is the ability to sharpen tools easily and well. Working with hand tools can be a frustrating experience unless you have sharp tools. The goal of this lesson is, with a mimimum of equipment, is for you to be able to produce razor sharp cutting edges on any tool blade consistently. This lesson focuses on honing. It was written by Maurice Fraser and is based on material and techniques taught in his classes at the Craft Students League in New York City. There are three areas of expertise in sharpening: The mechanics of what is a sharp edge. What are sharp tools We could describe a sharp tool as one you can shave with. Click on the picture to enlarge Why Sharpening Guides Make it Harder The most important thing you can come away with from this lesson is the technique for holding and moving a tool on a stone. Jigs and guides do have a place.

Charles Neil Woodworking - Welcome to Charles Neil Woodworking Why Pay? 24/7 Free Access to Free Woodworking Plans and Projects Joinery Basics The best way to hold together a high-end woodworking projects, whether you're building a timber-frame home, putting together a trestle table or making a step stool, is with a bit of glue and hand cut joints. It is easier to use mechanical fasteners, like nails and screws, but to add that look of first-class work, with smooth, metal free visible areas, nothing will do the job like a direct joint between parts, bonded with glue. Of course, the type of joint you need depends on a variety of factors, like the nature of the materials, the function of the joint, strength and appearance, available equipment, and your own level of skill. Joinery may be intimidating to the beginner, but, like any other building skill, all it takes is a bit of practice. Here we dissect the workings of two primary joints, the edge joint and the mortise and tenon.

Woodworking: Making wood projects without using nails, screws, or glue. Make knock-apart shelves, hinges, latches, books, chairs, cabinets, spice containers, doors, desks, and toolboxes using only wood to hold them together. Almost any wood project can be made without using any metal fasteners or glue. This instructable details the techniques and tools I have successfully used over the years to do this. So, rather than just showing a single project, I will demonstrate a system of fairly simple woodworking joints that you can use to create your own wood projects. Best of all, all the projects featured here can be entirely made with hand tools (although power tools will make it go faster and easier). Woodworking without metal or glue is of course nothing new. 1-Using these age old techniques, you can save on the cost of fasteners and expensive power tools. 2-Most projects can be easily taken apart for shipping or transport. 3-All-wood joints and fasteners allow for the wood to move with seasonal shrinkage and expansion. Pic 2 is a cabinet of pine and cedar.

DIY Succulent Pallet Table | Far Out Flora - StumbleUpon Max with the new Succulent Table. Can you believe that our latest DIY project was once just a couple of junky pallets and some scrappy table legs? Crazy…if I didn’t have photos, I wouldn’t believe it myself. The pallets. First bit of advice, deconstructing pallets are a big pain unless you have the right tools…and our hammer and wall scrapper wasn’t quite doing the trick. Couple good planks. Love the scares of time left on these chunks of pallet wood. Attaching the legs. After pulling apart two pallets, we used the 2 x 4 sized boards to make a rectangular frame to attached the appropriated table legs. Dry run for fittings. Like TV magic (and 2 days later), the table was more or less put together. Megan with some semps. After a weekend of slivers and sweat, we finally got to plant this baby. Getting messy. 3/8 inch holes where drilled in the bottom, and we decided to go with a fast draining cactus mix. Packing them in. Yeah, we didn’t hold back on jamming them. Succulents playing together.

Screws Small Encyclopedia Sometimes Sometimes You do not know, what screw you need to turn this piece of furniture. That is why this little encyclopedia was created. Screws Head Style Drive Types Washer Type Nut Types by Boltdepot.com