3D printing – An ‘Industrial Revolution in the Digital Age’? | Epicenter LONDON – As the fondue pots are cleared away, a sudden buzz ripples through the crowd packed into Val d’Isere’s Sur La Montagne restaurant. The room is heaving with 40 or so hard-living internet entrepreneurs and VCs here for a weekend of power-networking, skiing and après-ski partying — but all at once it’s a polished steel bracelet chain and a 2cm polyamide nylon sculpture that have captured the restaurant’s attention. Designed on computer screens and then built layer by layer in industrial 3D printing machines, these intricate trinkets are eliciting all the head-turning excitement of a Maserati roaring along La Croisette during the Cannes Film Festival. Lisa Harouni, whose company Digital Forming is bringing 3D printing to high-street fashion brands and consumer product designers, has just convinced even the most skeptical investors here that something transformative is about to happen to the whole business of making things. So what’s the next stage in this revolution? See Also:

3D-Drucker druckt Objekte aus Eis - 3Druck.com - alles über 3D-Drucker und Digital Fabricator Geht es um Materialien für 3D-Druck, sind der Kreativität scheinbar keine Grenzen gesetzt. Die McGill University (Montreal, Quebec) arbeitet an einem neuen 3D-Drucker der Objekte aus Eis druckt. Eine weitere unerwartete Berufsgruppe könnte zukünftig Konkurrenz von den Entwicklungen am 3D-Drucker Markt bekommen: Eisschnitzkünstler. Pieter Sijpkes, Professor an der McGill University in Montreal, Quebec arbeitet derzeit an einen 3D-Drucker der Objekte mittels 3D-Printer aus Eis erstellt. Der Druckprozess verläuft dabei ähnlich wie bei anderen 3D-Drucker. Sijpkes hebt den Kostenvorteil bei 3D-Druck mit Wasser hervor, der seiner Meinung nach für einige Designer interessant sein könne. Links:

Raspberry Pi The Raspberry Pi is a $25 computer that is powerful enough to run Quake 3, a pretty intense 3D video game. It plugs straight into a TV with an HDMI output and it's designed to be cheap enough that anyone can buy. So why is the Raspberry Pi foundation, the organization behind this charming device, making the computers in the first place? We spoke with Eben Upton, executive director of the Raspberry Pi foundation to find out why. Here's what we learned: It's primarily intended for the education market. And here's the full interview: BUSINESS INSIDER: Why did you guys want to build such a cheap computer? Eben Upton: We came up with the idea because we'd been interviewing potential undergraduates to come to Cambridge university about 5 years ago. We looked around for reasons why this happened. I started looking for a way you could provide a machine cheaply enough that you could give you children, settling on this $25, $35 price point. BI: So it's a shot at getting kids to learn how to program?

Wiki RepRap is humanity's first general-purpose self-replicating manufacturing machine. RepRap takes the form of a free desktop 3D printer capable of printing plastic objects. Since many parts of RepRap are made from plastic and RepRap prints those parts, RepRap self-replicates by making a kit of itself - a kit that anyone can assemble given time and materials. It also means that - if you've got a RepRap - you can print lots of useful stuff, and you can print another RepRap for a friend... RepRap is about making self-replicating machines, and making them freely available for the benefit of everyone. Reprap.org is a community project, which means you are welcome to edit most pages on this site, or better yet, create new pages of your own. RepRap was the first of the low-cost 3D printers, and the RepRap Project started the open-source 3D printer revolution. RepRap was voted the most significant 3D-printed object in 2017. About | Development | Community | RepRap Machines | Resources | Policy

Physibles: Pirate Bay wird dreidimensional Das Angebot The Pirate Bay hat eine neue Kategorie eingerichtet: Nutzer können darüber jetzt auch 3D-Designs suchen, die sie dann auf einem 3D-Drucker ausgeben lassen. Physibles nennen die Pirate-Bay-Gründer diese Klasse von Daten. "Wir glauben, dass der nächste Schritt beim Kopieren derjenige von der digitalen zur physischen Form sein wird. Es geht um physische Objekte", schreiben sie in ihrem Blog. Es gebe einen großen gesellschaftlichen Nutzen, wenn Nutzer Gegenstände ausdruckten statt sie zu kaufen. Eines der auf Pirate Bay angebotenen Physibles ist übrigens das Piratenschiff, das das Logo des Angebots bildet.

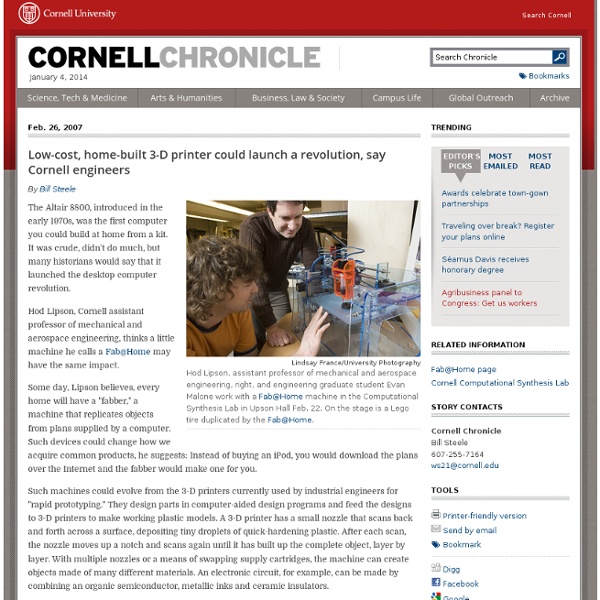

Startups Rapid prototyping 3D model slicing 'Rapid prototyping' is a group of techniques used to quickly fabricate a scale model of a physical part or assembly using three-dimensional computer aided design (CAD) data.[1][2] Construction of the part or assembly is usually done using 3D printing or "additive layer manufacturing" technology.[3] The first methods for rapid prototyping became available in the late 1980s and were used to produce models and prototype parts. Today, they are used for a wide range of applications[4] and are used to manufacture production-quality parts in relatively small numbers if desired without the typical unfavorable short-run economics. As with CNC subtractive methods, the computer-aided-design - computer-aided manufacturing CAD-CAM workflow in the traditional Rapid Prototyping process starts with the creation of geometric data, either as a 3D solid using a CAD workstation, or 2D slices using a scanning device. History[edit] See also[edit] References[edit] Bibliography[edit]

Cocoon Lamp: Objet zeigt die Möglichkeiten seiner 3D-Drucker - 3Druck.com - alles über 3D-Drucker und Digital Fabricator Zum Testen der Leistungsfähigkeit von 3D-Drucker, scheinen sich vor allem Vasen und Lampen zu eignen. Nach Shapeways´ großer Anzahl von Vasen und Voxeljets´ kürzlich vorgestellter Designerlampe zeigt auch Objet was sein neuer Connex Multimaterial Drucker alles kann. Inspiriert von Neri Oxman´s “the beast” entwicklete der Designer Patric Günther von Voxel Studios eine umwerfende Lampe namens Cocoon, um die Möglichkeiten des Polyjet 3D-Druckers (der mit mehreren Materialien gleichzeitig arbeiten kann) zu zeigen. Die metamorphose Lampe besteht aus den drei Materialien “veroWhite”, “TangoBlackPlus” und einer Mischung namens “DigitalMaterial” und kann verschieden positioniert werden. Weitere Bilder: Links:

TechStars Launches Accelerato.rs, A Common App For Startups And A Results Tracker For Accelerators For a young startup, sometimes you want any funding you can get. For an incubator program, sometimes any startup is what you’re looking for. Finding each other won’t necessarily make either one successful, but more pairings might help overall. Or so believes TechStars, which is launching what it intends to be the Common Application of the startup world. Called Accelerato.rs, the application is a standard online form that asks founders basic investor-type questions, and lets them write one version then send it to any of the dozen or so participating programs. “One of the big things that a lot of the accelerators are looking for are more applications,” TechStars cofounder David Cohen tells me. ” Y Combinator, Seedcamp, TechStars and some of the other big accelerators are getting thousands of applications but only accepting a few percentage points.” The foundation will also be studying how participating startups do to better understand what makes accelerators successful.

3D Printing: Bringing Fantasy to Reality Times are changing and with time definitions of needs are also changing. There were times when necessities were few, with all other things falling into the comfort or luxury zone. With technological advancements and easy availability many luxury items have shifted into the necessary and comfort zone. Take for example 3D printing technology. It is true that 3D printers are not yet that popular but at the rate at which they are growing, it will not be long before every household also owns a piece. Every one has a dream and a fantasy world but not all have the means and ability to bring it to life. With everything being machine made this printer could to some extent take away the pleasure of 3D modeling that many artists excel in. Benefits of 3D printing are numerous and can be used for purposes such as education, architecture, art, craft, product designing, and many more areas.

Interactive Fabrication » Fabricate Yourself Fabricate Yourself is a project that documented the Tangible, Embedded and Embodied Interaction Conference. Usually we think of documentation in terms of text, photography and video, but given the tangible theme of the conference we decided to engage the community by capturing and fabricating small 3D models of attendees. This enabled us to build a tangible model of the event and fabricate it piece by piece during the conference. Attendees firstly capture their favorite pose using a Microsoft Kinect. Dovetail joints are automatically added to the side of the models so they can be snapped together. The STL files were printed using a Dimension uPrint 3D printer kindly provided by Stratasys. Below you can see the models packed on to the 3D printing base. As we wanted to be able to fabricate a large number of models, we kept the size of the pieces down to approximately 3x3cm. To print at the 3x3cm size we only needed to use one quarter of the full Kinect resolution. Created by Karl D.D.

Jewelry Site Plukka Turns Group Buying On Its Head The Spark of Genius Series highlights a unique feature of startups and is made possible by Microsoft BizSpark. If you would like to have your startup considered for inclusion, please see the details here. Name: Plukka Quick Pitch: Social shopping with a group buying twist — more jewelry buyers means a lower price for everyone. Genius Idea: Applying the group-buying model to the manufacturing process, not just the final product. Today's group buying sites often exist to get rid of leftover inventory from last season; both the designer and the website get a cut, while you get the last season's threads for half the price, three months late. Plukka founder Joanne Ooi says that its test-demand-before-you-create-supply model means that the designs are riskier and more creative, since the company isn't investing in manufacturing until sales are locked in. Plukka hopes to have a mobile app on the market by the end of 2012. Series Supported by Microsoft BizSpark

Additive manufacturing An ORDbot Quantum 3D printer. 3D printing or additive manufacturing[1] is a process of making a three-dimensional solid object of virtually any shape from a digital model. 3D printing is achieved using an additive process, where successive layers of material are laid down in different shapes.[2] 3D printing is also considered distinct from traditional machining techniques, which mostly rely on the removal of material by methods such as cutting or drilling (subtractive processes). A 3D printer is a limited type of industrial robot that is capable of carrying out an additive process under computer control. The 3D printing technology is used for both prototyping and distributed manufacturing with applications in architecture, construction (AEC), industrial design, automotive, aerospace, military, engineering, dental and medical industries, biotech (human tissue replacement), fashion, footwear, jewelry, eyewear, education, geographic information systems, food, and many other fields.

VRZ1: Das Design-Fahrrad aus dem 3D-Drucker - 3Druck.com - alles über 3D-Drucker und Digital Fabricator Nach EADS stellt nun auch eine deutsche Designmanufaktur namens Vorwaertz ein Fahrrad aus dem 3D-Drucker vor. Bei diesem Design-Projekt wurden sämtliche Stahlmuffen des Fahrrades mittels 3D-Drucker via Laser Sintering aus Stahl gedruckt und anschließend noch händisch nachbearbeitet. Die Muffen wurden anschließend mit dem Carbonfaser Rahmen verklebt. Das Resultat ist das hübsche Designer Bahnrad VRZ1. Ein ebenfalls kunstvolles Video zeigt den Herstellungsprozess: Bereits letztes Jahr stellte der europäische Flugzeugbauer EADS ein komplett gedrucktes Fahrrad aus Nylon mit dem Namen “Airbike” vor. Links: Quelle: Notcot.org