How Car Steering Works"

Since the power-steering pump on most cars today runs constantly, pumping fluid all the time, it wastes horsepower. This wasted power translates into wasted fuel. You can expect to see several innovations that will improve fuel economy. One of the coolest ideas on the drawing board is the "steer-by-wire" or "drive-by-wire" system. General Motors has introduced a concept car, the Hy-wire, that features this type of driving system. In the past fifty years, car steering systems haven't changed much. For more information on steering systems and related topics, check out the links on the next page.

How Car Steering Works"

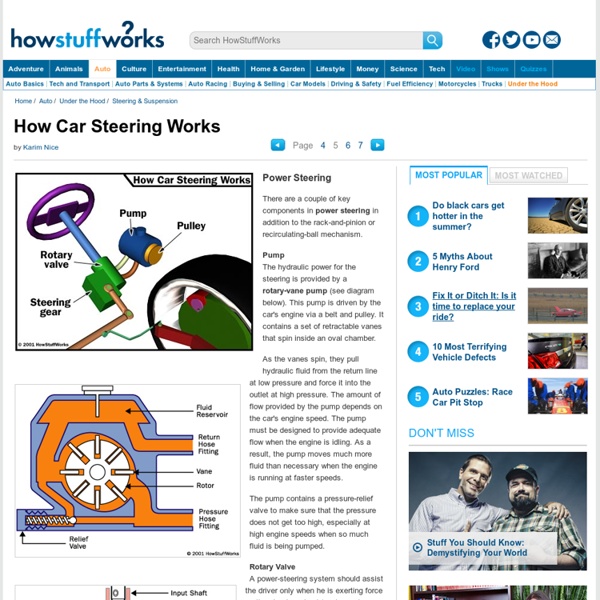

Recirculating-ball steering is used on many trucks and SUVs today. The linkage that turns the wheels is slightly different than on a rack-and-pinion system. The recirculating-ball steering gear contains a worm gear. You can image the gear in two parts. The first part is a block of metal with a threaded hole in it. Instead of the bolt directly engaging the threads in the block, all of the threads are filled with ball bearings that recirculate through the gear as it turns. Power steering in a recirculating-ball system works similarly to a rack-and-pinion system. Now let's take a look at the other components that make up a power-steering system.

Car Suspension Parts"

Chassis The suspension of a car is actually part of the chassis, which comprises all of the important systems located beneath the car's body. These systems include: The frame - structural, load-carrying component that supports the car's engine and body, which are in turn supported by the suspension The suspension system - setup that supports weight, absorbs and dampens shock and helps maintain tire contact The steering system - mechanism that enables the driver to guide and direct the vehicle The tires and wheels - components that make vehicle motion possible by way of grip and/or friction with the road So the suspension is just one of the major systems in any vehicle. With this big-picture overview in mind, it's time to look at the three fundamental components of any suspension: springs, dampers and anti-sway bars. Springs Today's springing systems are based on one of four basic designs:

How Car Steering Works"

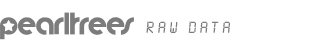

Rack-and-pinion steering is quickly becoming the most common type of steering on cars, small trucks and SUVs. It is actually a pretty simple mechanism. A rack-and-pinion gearset is enclosed in a metal tube, with each end of the rack protruding from the tube. The pinion gear is attached to the steering shaft. The rack-and-pinion gearset does two things: It converts the rotational motion of the steering wheel into the linear motion needed to turn the wheels.It provides a gear reduction, making it easier to turn the wheels. On most cars, it takes three to four complete revolutions of the steering wheel to make the wheels turn from lock to lock (from far left to far right). The steering ratio is the ratio of how far you turn the steering wheel to how far the wheels turn. Generally, lighter, sportier cars have lower steering ratios than larger cars and trucks. Power Rack-and-pinion When the rack-and-pinion is in a power-steering system, the rack has a slightly different design.

Dampers: Shocks"

Unless a dampening structure is present, a car spring will extend and release the energy it absorbs from a bump at an uncontrolled rate. The spring will continue to bounce at its natural frequency until all of the energy originally put into it is used up. A suspension built on springs alone would make for an extremely bouncy ride and, depending on the terrain, an uncontrollable car. Enter the shock absorber, or snubber, a device that controls unwanted spring motion through a process known as dampening. Shock absorbers slow down and reduce the magnitude of vibratory motions by turning the kinetic energy of suspension movement into heat energy that can be dissipated through hydraulic fluid. To understand how this works, it's best to look inside a shock absorber to see its structure and function. A shock absorber is basically an oil pump placed between the frame of the car and the wheels. Shock absorbers work in two cycles -- the compression cycle and the extension cycle.

Front Suspensions"

So far, our discussions have focused on how springs and dampers function on any given wheel. But the four wheels of a car work together in two independent systems -- the two wheels connected by the front axle and the two wheels connected by the rear axle. That means that a car can and usually does have a different type of suspension on the front and back. Much is determined by whether a rigid axle binds the wheels or if the wheels are permitted to move independently. Dependent Front Suspensions Dependent front suspensions have a rigid front axle that connects the front wheels. Independent Front Suspensions In this setup, the front wheels are allowed to move independently. The MacPherson strut combines a shock absorber and a coil spring into a single unit. Photo courtesy Honda Motor Co., Ltd.Double-wishbone suspension on Honda Accord 2005 Coupe The double-wishbone suspension, also known as an A-arm suspension, is another common type of front independent suspension.

Steering Column

Basic Suspension Systems

Independent Suspension

How the Ariel Atom Works"

The Atom features a double-wishbone suspension front and rear, which consists of a short upper control arm and a longer lower control arm that hold the wheel to the frame. The control arms operate much like a hinge, allowing the wheel to move up and down. Rubber bushings at the inboard end of the control arms allow the wheel to pivot. The bushings also help to absorb road shock and reduce noise entering the vehicle. Overall, the double-wishbone suspension allows for more control over the camber angle of the wheels. Camber angle describes the degree to which the wheels tilt in and out. Koni-manufactured dampers at each wishbone provide additional adjustability. The braking system of the Atom offers another opportunity to fine-tune the driving experience. Next, we'll take a look at the origins of the Atom.

Top 10 Everyday Car Technologies that Came from Racing"

Most drivers in the United States use automatic transmissions, which makes cruising around town worlds apart from a hard-shifting lap on a Formula One track. But, the purpose of a transmission in a race car and a road car are the same: it translates the engine's power to the car's wheels. While an automatic transmission shifts gears with no input from the driver (other than the initial selection of Drive), a manual transmission lets the driver control the flow of power from the engine to the wheels. Race car drivers want the control of a manual transmission, but the manual process can be too slow and prone to human error. Enter Direct-Shift Gearboxes (DSG) and clutchless manual transmissions. DSGs actually work like two transmissions: one dials in the odd numbered gears and one dials in the even numbered gears. Running late?