http://www.youtube.com/watch?v=ptUj8JRAYu8

Related: Impression 3DFilabot, le robot ménager qui recycle vos plastiques pour l’impression 3D L’impression 3D, c’est LE truc en vogue depuis plusieurs mois. Révolution des Makers oblige, les garages modernes appelé « Fab Lab » se multiplient un peu partout dans le monde, et les plus geeks travaillent sur les améliorations à apporter à cet outil encore un peu venu du futur que sont les imprimantes 3D. Oui mais voilà, ces imprimantes, pour imprimer, consomment du plastique. Et alors que je me demandais l’autre jour si ces outils ne permettraient pas de créer un univers d’économie circulaire à la maison, je suis tombée nez à nez avec Filabot. Magie !

The Free Universal Construction Kit Ever wanted to connect your Legos and Tinkertoys together? Now you can — and much more. Announcing the Free Universal Construction Kit: a set of adapters for complete interoperability between 10 popular construction toys. Fig. 1. Interactive Fabrication » Fabricate Yourself Fabricate Yourself is a project that documented the Tangible, Embedded and Embodied Interaction Conference. Usually we think of documentation in terms of text, photography and video, but given the tangible theme of the conference we decided to engage the community by capturing and fabricating small 3D models of attendees. This enabled us to build a tangible model of the event and fabricate it piece by piece during the conference. Attendees firstly capture their favorite pose using a Microsoft Kinect.

Comment bien tester son imprimante 3D ? - Makershop.fr Le marché de l’impression 3D grandissant chaque jour, il est de plus en plus difficile de trouver l’imprimante ou le matériau qui conviendra à nos besoins. D’autant plus que les machines récentes mettent de plus en plus l’accent sur les performances. Heureusement, des modèles de test à imprimer permettent maintenant de mettre en avant les forces ou faiblesses de nos machines ou filaments. Nous allons à travers cet article vous présenter quelques uns des tests les plus répandus et comment décrypter les résultats obtenus.

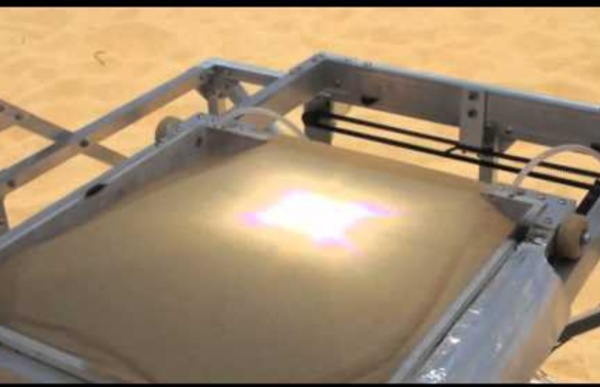

Les types d'imprimantes 3D Vous retrouverez dans cet article les principales techniques utilisées par les imprimantes 3D pour créer les objets. 3 grands types se dégagent. Il s’agit de la Stéréolithographie (SLA), le dépôt de matière en fusion (Fused Deposition Modeling – FDM) et le forgeage par application laser (Selective Laser Sintering – SLS). Stereolithography

Makers, La nouvelle révolution industrielle Imprimantes 3D, découpeuses laser, logiciels et matériels open source sont désormais à la portée de tous et fabriquer des objets, chez soi comme à son bureau, va rapidement devenir aussi courant que de retoucher des photos… La démocratisation des outils de production va-t-elle déclencher une nouvelle révolution industrielle, portée par les Makers ? C'est le point de vue défendu par Chris Anderson, rédacteur en chef de Wired et auteur du best-seller mondial La Longue Traîne, qui expose ici les caractéristiques de ce mouvement en plein essor : • Les Makers utilisent les outils numériques pour créer de nouveaux produits et réaliser des prototypes. • Grâce à l'open source, ils mettent en commun leurs idées et leurs connaissances, acquérant ainsi un immense savoir collectif. • Leurs initiatives dépassent le stade du passe-temps et débouchent désormais sur de véritables entreprises, déjà présentes dans le tissu économique.

Impression tridimensionnelle - Wikipédia Un article de Wikipédia, l'encyclopédie libre. L'impression 3D ou impression tridimensionnelle sont les termes courants utilisés pour parler des procédés de fabrication additive. Initialement, en raison de leurs défauts originels, ces procédés ont été développés pour le prototypage rapide, mais maintenant ils sont de plus en plus utilisés pour la fabrication de pièces fonctionnelles. Bien que d'autres existent, voici quelques technologies qui coexistent : le FDM (Fuse Deposition Modeling : modelage par dépôt de matière en fusion), la SLA (Stéréolithographie : une lumière UV solidifie une couche de plastique liquide) et le frittage sélectif par laser (un laser agglomère une couche de poudre). L'impression tri-dimensionnelle permet de produire un objet réel : un opérateur dessine l'objet sur un écran en utilisant un outil de Conception assistée par ordinateur (CAO). En 2013[modifier | modifier le code]

L’impression 3D et le futur des objets Juin 2013 Par Catherine Jewell, Division des communications, OMPI Avez-vous déjà été à la recherche d’une lampe sans pouvoir trouver celle qu’il vous fallait ou avez-vous dû attendre des mois une pièce détachée d’un appareil électroménager qui n’est plus fabriqué? Ces frustrations appartiendront bientôt au passé. L’impression 3D à haute performance, ou fabrication additive, qui a été mise au point pour la première fois en laboratoire il y a une trentaine d’années, est désormais à la portée des consommateurs. Histoire de l'impression 3D Si le phénomène Impression 3D s’emballe depuis quelques années, le procédé existe pourtant depuis le milieu des années 80. Voici un bref historique de l’impression 3D présentant les grands tournants techniques ou pratiques. Constructeurs de machines, lanceurs de projets, scientifiques ; toute une communauté a participé au développement de l’impression 3D en améliorant les technologies ou en créant des usages innovants. 1983-1986 : La naissance de l’impression 3D 1983 pour certains, 1984 pour d’autres tout le monde s’accorde toutefois à attribuer la paternité de l’impression 3D à Charles Hull (ci-dessus présentant le procédé de stéréolytographie) aujourd’hui vice-président de 3D Systems.

Premier livre / Impression 3D ! Mathilde Berchon Mise à jour au 8 août : Nous venons d’apprendre ce jour le 8 août que le livre figure parmi les meilleures ventes de la librairie Eyrolles, bravo à Mathilde ! Vous êtes nombreux à avoir lu »Makers » de Chris Anderson paru en Octobre 2012, voici le premier livre écrit sur le sujet par un Français… en l’occurrence une charmante Française. Mathilde Berchon a eu la gentillesse de répondre à nos questions depuis San Francisco pour la sortie de son livre »L’impression 3D » aux Editions Eyrolles. 3DN: Mathilde, dites nous un peu plus sur vous même ?