Lasersaur Lasersaur The Lasersaur is an open source laser cutter. We designed it to fill the need of makers, artist and scientist who wanted a safe and highly-capable machine. Unlike others it comes fully loaded with knowledge to run, maintain, and modify. Since its conception, Nortd Labs and the Lasersaur community has generated knowledge to develop a comprehensive system. How can you Contribute? Unlike software, hardware RD is costly even when living off of Ramen. Short on cash? $32 Beta Access: Support the project and get full access to design documents, community (mailing list), and software before the project goes fully open source. $(any) Project Support: Simply want to support the project? We Accept Bitcoin! Credits Mad props to reprap.org, www.cnczone.com, arduino.cc, grbl, buildlog.org, and their giants' shoulders.

Inside 3D Printing | Conference and Expo for Additive Manufacturing Professionals This event has ended. Hope to see you at a future event! 3D printing is impacting what we eat, wear, build, drive, fly, and shoot. Inside 3D Printing Conference & Expo, “the” B2B tradeshow for the 3D printing industry, will continue its world tour in San Jose this September 17-18. The event, programmed by Hod Lipson, will feature two full days of conference sessions with two tracks to choose from. Featured Keynote Speakers Keith Murphy, CEO and Co-Founder of Organovo, will discuss how 3D bioprinting is changing the shape of medical research and practice during his keynote presentation. Avi Reichental, President & CEO of 3D Systems, will discuss how 3D printing is revolutionizing the manufacturing industry. 3D Systems is one of the fasted growing companies, according to Forbes. S. Who Should Attend? An Inside Look at the Conference Watch 3D printers in action and meet with top 3D printing companies and experts at Inside 3D Printing Conference & Expo. Press Coverage

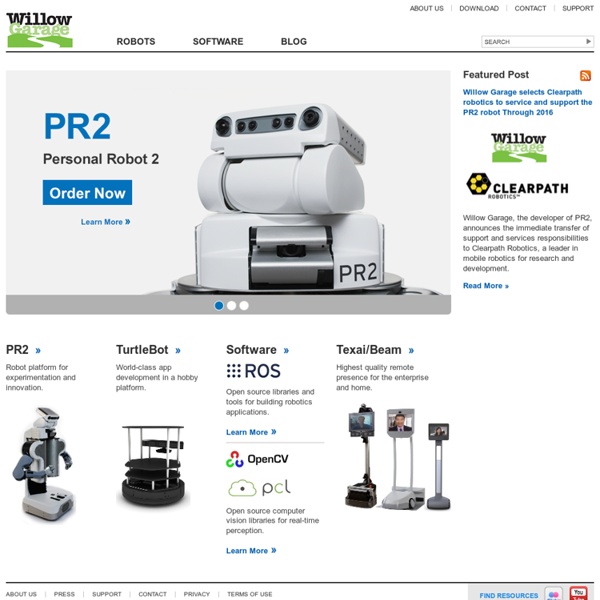

Willow Garage Un article de Wikipédia, l'encyclopédie libre. le robot PR2 de Willow Garage Willow Garage est un laboratoire de recherche en robotique créé fin 2006 qui conçoit des robots et développe des logiciels pour la robotique[o 1]. Il est principalement connu pour son robot de taille humaine PR2, qui possède deux bras, se déplace sur des roues, et peut accueillir toutes sortes d'applications. Il développe également Robot Operating System (ROS), un système d'exploitation open source pour robots[o 2],[1], et OpenCV, une bibliothèque graphique open source [o 3]. Willow Garage est situé à Menlo Park, en Californie[o 4],[2], et emploie une cinquantaine d'employés[3]. Historique[modifier | modifier le code] Willow Garage est créé fin 2006 par Scott Hassan, ancien employé de Google[4],[5],[2] Durant l'été 2009, Willow Garage atteint son deuxième objectif : construire un robot qui peut ouvrir les portes, découvrir les prises électriques et s'y brancher[6],[7],[o 5]. PR2[modifier | modifier le code]

telerob | The Remote Handling People Cobham Unmanned Systems is a leading provider of integrated homeland security solutions and unmanned platforms, utilizing over 30 years of expertise in this highly specialised field. Cobham Unmanned System' mission is "To develop machines, equipment and systems that protect or replace human beings in situations where their presence would be either impossible or place them at great risk". Whether the task at hand is disarming an Improvised Explosive Device (IED) with a remote controlled robot; investigating NBC hazards with an unmanned sensor platform; or deploying mobile, fully networked measurement, monitoring and intervention systems to ensure the safety and security of critical infrastructure, Cobham's top priority is always the protection of people and their surroundings.

DIY Projects, Inspiration, How-tos, Hacks, Mods & More @ Makezine.com - Tweak Technology to Your Will The format of this book is very different from the regular O'Reilly books. It is written by a geek for geeks. So it doesn't start with a smooth introduction about the basics. It seems to have a rocky start since a lot of assumptions is made about the reader. The diagrams also seem to be hand-drawn on napkins. Chapter 4 really rocks. Overall the book is excellent for getting started with Arduino. Wiki RepRap is humanity's first general-purpose self-replicating manufacturing machine. RepRap takes the form of a free desktop 3D printer capable of printing plastic objects. Since many parts of RepRap are made from plastic and RepRap prints those parts, RepRap self-replicates by making a kit of itself - a kit that anyone can assemble given time and materials. It also means that - if you've got a RepRap - you can print lots of useful stuff, and you can print another RepRap for a friend... RepRap is about making self-replicating machines, and making them freely available for the benefit of everyone. Reprap.org is a community project, which means you are welcome to edit most pages on this site, or better yet, create new pages of your own. RepRap was the first of the low-cost 3D printers, and the RepRap Project started the open-source 3D printer revolution. RepRap was voted the most significant 3D-printed object in 2017. About | Development | Community | RepRap Machines | Resources | Policy

Freedom Of Creation | Pioneers in 3D Printed Designs Quand le robot décide pour l'homme du confort de son véhicule Ruth, développé par Ford, estime si les matières qui composent l'intérieur d'un véhicule correspondent aux attentes des consommateurs. Il se repose sur les remarques de ces derniers pour réaliser ses calculs. Pour s'assurer que les éléments placés à l'intérieur d'un véhicule correspondent aux attentes des utilisateurs, les ingénieurs de Ford ont décidé de les tester non pas auprès de volontaires humains mais d'un robot. Robot - Product - FANUC Robot Lineup Intelligence Vision and force sensing provide superior performance with integrated human skills. Integrated Vision Function iRVision All controllers come standard with Vision function iRVision, making your system significantly intelligent. Networking Networking promotes the integrated management at production floors. Versatile functionality for communication in the robot controller R-30iB enable to network multi robot system with PC, PLC and peripherals for control and production management. Robotization Versatile process solutions for applications with flexibility contribute efficient automatization of any requirements in production. Various application packages and software tools make the most of the flexibility of articulated robots for gantry loaders and scalar robots for which use conditions are restricted.

Labs / DC Motor Control Using an H-Bridge Overview In this tutorial, you'll learn how to control a DC motor's direction using an H-bridge. To reverse a DC motor, you need to be able to reverse the direction of the current in the motor. The easiest way to do this is using an H-bridge circuit. There are many different models and brands of H-Bridge. This tutorial uses one of the most basic, a Texas Instruments L293NE or a Texas Instruments SN754410. If you simply want to turn a motor on and off, and don't need to reverse it, for example if you're controlling a fan, try the tutorial on controlling high current loads with transistors. (:toc Table of Contents:) Parts For this lab you'll need: Solderless breadboard 22-AWG hookup wire Arduino Microcontroller module Light Emiting Diodes, LED 10Kohm resistors Switch L293NE or SN754410 H-bridge 12V DC power supply DC Motor Prepare the breadboard Connect power and ground on the breadboard to power and ground from the microcontroller. (Diagram made with Fritzing) Add a Digital Input (a switch) Find a motor