Synthetic Biology Open Language

The Rise of Desktop Manufacturing in the Great Recession

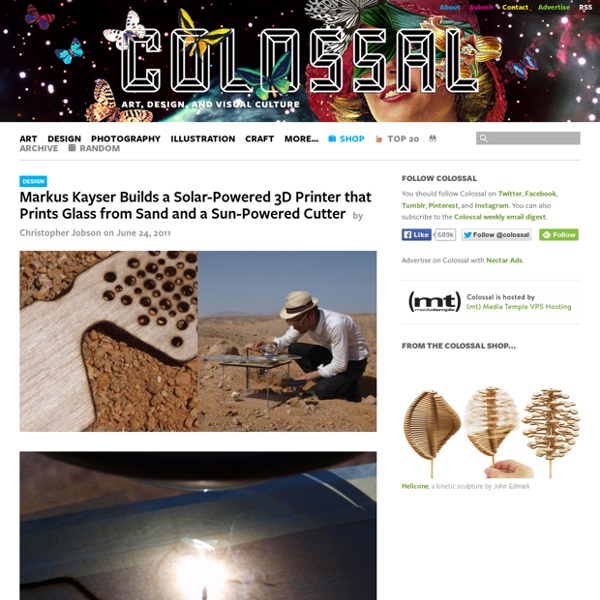

In the last post, we talked about the changing nature of markets and marketing in the Great Recession. This time we'll focus in on one of the results of these changes: Desktop Manufacturing. In the old days, it could cost upwards of $10,000 to $20,000 just to create the custom molds and dies required to produce an item in a factory. Then you had to cover the costs associated with prepping the manufacturing line to produce your item. As a result, your up-front costs could easily surpass $50,000 before your first item rolled off of the line. To make the effort worthwhile, you needed to produce a large number of items to spread these fixed costs around. Today, you can get small runs of custom manufactured items for less than $100. A Laser-Cut Lamp Design Today, both of these technologies are being used mostly by hobbyist and early adopters, and both are undergoing rapid adoption and enhancement. The ReprapSelf-Replicating 3D Printer

Why is Open Hardware inherently sustainable?

Reflections on the role of Open Hardware and Peer Production in insuring a sustainable world In this article, I want to list the reasons why I believe that the trend towards open and distributed manufacturing is a vital part of ensuring a sustainable society. For those that are not familiar with it, open hardware is a practice where designs are shared through open licenses in a community, and those designs can then be used by manufacturers, who can make and sell the product, eventually making a profit, but they cannot rely on any rents deriving from intellectual property. The first reason that open hardware is a sustainable practice is that innovation cannot be privatized and taken away from the benefit of collective humanity. The second reason that open hardware contributes to sustainability, and actually is “inherently” sustainable, lies in the motivation behind the research, innovation, and production. Challenges The main issues center around the funding mechanism.

The Make-It-Yourself Manufacturing Turn

The rise of online shopping has brought about a world in which consumers no longer have to leave the comfort of their own sofas to order any product their hearts could desire. But a series of changes in personal manufacturing technology could leave even online distributors in the dust. In the near future, any slob will be able to print out a toothbrush like we would a school report, while creators, innovators, and entrepreneurs will have access to unprecedented opportunities. In their report "Factory @ Home: The Emerging Economy of Personal Fabrication", Cornell engineering professor Hod Lipson and consultant Melba Kurman take a look at the possibilities implicit in these new technologies and some things lawmakers and the public can do to make small-scale home manufacturing a reality: A number of converging factors are bringing industrial-scale design and manufacturing tools to a tipping point where they will become cheap, reliable, easy and versatile enough for personal use.

The attention economy: curation by duration

This Short Manifesto on the Future of Attention by Michael Erard pushed a lot of my buttons, and I reckon it’ll be of some considerable interest to other art creators and consumers (writers and readers, for example, which is most of you lot): I imagine attention festivals: week-long multimedia, cross-industry carnivals of readings, installations, and performances, where you go from a tent with 30-second films, guitar solos, 10-minute video games, and haiku to the tent with only Andy Warhol movies, to a myriad of venues with other media forms and activities requiring other attention lengths. In the Nano Tent, you can hear ringtones and read tweets. Has a hint of the science fictional about it, but doesn’t seem implausible by any means given the way the web is mutating creation and commerce. I imagine an attention tax that aspiring cultural producers must pay. Be Sociable, Share!

A manifesto on Peer-to-Peer energy production

This essay, written in a manifesto form, addresses some crucial issues related to the timely topic of the distributed or Peer-to-Peer (P2P) energy production. It uses the emerging mode of the P2P production in the immaterial field of production (information, culture, knowledge) as a point of departure to realize the dynamics of this new energy technology and shed light on its socio-economic aspects. Source: Papanikolaou, G., and Kostakis, V. (2011) “An Essay on P2P Energy Policy”, in Acoustic Space No. 8: ENERGY, Ed. by Smite, R., Medosch, A., Mey, K., Smits, R., Riga: RIXC; Liepaja: LiepU MPLab, 26-30. Excerpts from this first article is followed up by a reportage on municipal initiatives in the U.S. 1. George Papanikolaou and Vasilis Kostakis: A radical change in the organization of information production has been observed during last decades. We, therefore, have to invent new indexes that will incorporate the real costs for the society and the environment. 2. Frances Beinecke writes: 3.

The Homebrew Industrial Revolution

Grilling Peer Production with Weber « Part.Public.Part.Lab

Kreiss, D., M. Finn, and F. Turner. 2010. “ The Limits of Peer Production: Some Reminders from Max Weber for the Network Society. ” New Media & Societ y 13:243-259. (Accessed December 14, 2010). A new article in New Media and Society proposes that we go back to our Weber for a fresh wake-up call concerning the heady promises of peer production. It’s a good article for one good reason: it characterizes some of the basic features of what they call the “consensus view” of peer production. The consensus view includes claims that 1) peer production is psychologically gratifying labor (which is good), 2) it leads to egalitarianism and efficiency 3) it realizes ethical relationships between collaborators (?) So for instance, (1) psychological gratification is discussed in terms of the separation of public and private life. (2) egalitarianism and efficiency. 5) And of course it is not non-market or non-proprietary. Comments are closed.