HOW TO GET WHAT YOU WANT

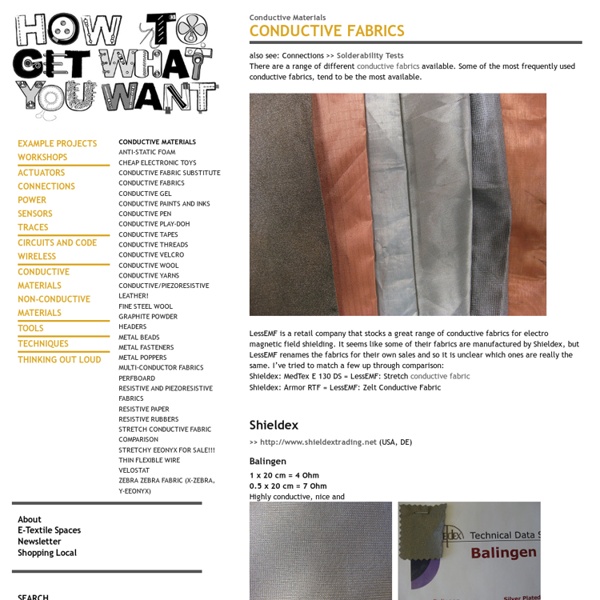

also see: Connections >> Solderability Tests There are a range of different conductive fabrics available. Some of the most frequently used conductive fabrics, tend to be the most available. LessEMF is a retail company that stocks a great range of conductive fabrics for electro magnetic field shielding. It seems like some of their fabrics are manufactured by Shieldex, but LessEMF renames the fabrics for their own sales and so it is unclear which ones are really the same. I’ve tried to match a few up through comparison: Shieldex: MedTex E 130 DS = LessEMF: Stretch conductive fabric Shieldex: Armor RTF = LessEMF: Zelt Conductive Fabric Shieldex >> (USA, DE) Balingen 1 x 20 cm = 4 Ohm 0.5 x 20 cm = 7 Ohm Highly conductive, nice and MedTex E 130 DS 1 x 20 cm = 13 Ohm 0.5 x 20 cm = 23 Ohm Super similar, if not the same as LessEMF’s Stretch Conductive Fabric. MedTex P 180 OS From the small sample I have it looks like a nice stretch conductive fabric to work with. Toray

HOW TO GET WHAT YOU WANT

Welcome to the KOBAKANT DIY Wearable Technology Documentation Workshops least likely scenario This workshop is part of a course at the Ernst Busch Hochschule in Berlin. Workshops soft sensors for soft bodies FURTHER_READING_WATCHING_LISTENING_ Elektronische Textilien als Material und Werkzeug_ Hannah Perner-Wilson, Irene Posch, 2020 “Welche Fasern leiten Strom? Workshops connecting bubbles This semester, we are sitting in a strange bubble at home. Sensors 6 really wearable sensors The textile sensors on our website are often not designed to be manipulated with your hands. Workshops soft interactive technologies This workshop is a part of a course at the Art Academy Weissensee Berlin. Workshops ETextile Adventures This workshop is part of a course at the Ernst Busch Hochschule in Berlin. Sensors Sole Sensing Rather simple way of making insoles with 3 pressure sensors located at different pressure points of the foot on the ground. Actuators Vibe Modules Workshops from SPACE to SPACE with NO SCREENS? Power

Reconnaissance de mouvement

Ces deux vidéos montrent l'utilisation d'une wiimote et notre logiciel (SDK) utilisant un "réseau de neurones" pour faire de la reconnaissance de mouvements. La première vidéo montre la phase d'enregistrement ou "motion capture" Une ligne de commande plus tard ... L'utilisation du système Il ne reste plus qu'à inventer des mouvements et développer des minijeux... On utilisera ce système de reconnaissance dans le TP du cours de 4A "neural computing", et quelques projets PAIR (4A aussi). Si cet article vous a plus merci de voter en cliquant sur cette icone.

Related:

Related: