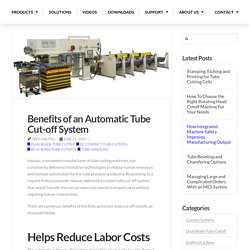

Benefits of an Automatic Tube Cut-off System - Hautau. Hautau, a renowned manufacturer of tube cutting machines, has consistently delivered innovative technologies to reduce human resources and increase automation for the tube processing industry.

Responding to a request from a customer, Hautau delivered a custom tube cut-off system that would transfer the cut-up tubes into special transport carts without requiring human intervention. There are numerous benefits of this fully automatic tube cut-off system, as discussed below. Hautau featured on Manufacturing Marvels® - Hautau. Manufacturing Marvels® will showcase Hautau Tube Cutoff Systems in their June 23rd episode Airing nationally on the Fox Business Network, Manufacturing Marvels® spotlights North American manufacturers and their products and services in a two-minute evening segment created by award-winning producers Bob and Jerry May, award-winning director Bryan McCullough, and narrated by nationally acclaimed voice talent John Criswell – a CBS and ABC news anchor of over 40 years.

In this episode, Manufacturing Marvels® showcases Hautau’s advanced, dependable tube cutting and processing machines built in Brookville Indiana. Hautau machines are found in production facilities across America in the automotive, hydraulics, material handling, and other tube processing industries – where precision and uptime are critical. Hautau Voted One of The Top Machine Tool Solution Providers in 2020.

Hautau Tube Cutoff Systems was recently named one of the Top Ten Machine Tool Solution Providers in 2020 by Manufacturing Technology Insights.

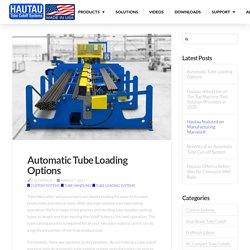

This publication is one of the top in our industry, and we’re honored to be included among other commendable companies who excel in the manufacturing business. There are many aspects of our business that have allowed Hautau to be recognized as one of the top machine tool solution providers in the country. Experience. Automatic Tube Loading Options - Hautau. Tube fabricators and processors are always looking for ways to increase production and reduce costs.

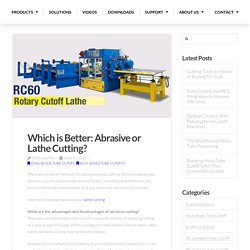

With any high-volume tube fabricating operation, the first steps in the process are handling tube bundles, cutting tubes to length and then moving the cutoff tubes to the next operation. This tube cutting process is required for all your raw tube material, and it can be a significant portion of the final product cost. Which is Better: Abrasive or Lathe Cutting? - Hautau. There are a host of methods for tubing and pipe cutting.

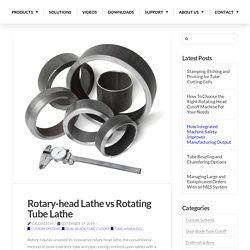

Before making your decision, you should consider several factors, including wall thickness, the end-conditioning requirements, and any necessary secondary processes. Here, we’ll compare abrasive and lathe cutting. What are the advantages and disadvantages of abrasive cutting? This manual method does not cut with saw teeth. Rotary-head Lathe vs Rotating Tube Lathe - Hautau. Before Hautau unveiled its innovative rotary head lathe, the conventional method of close-tolerance tube and pipe cutting centered upon lathes with a fixed, stationary tool that would cut one end as the workpiece rotated – the rotating tube lathe approach.

For many years these conventional lathes were the only game in town, but they had drawbacks. The workpiece could not be fully-chamfered on both ends. Because the tube rotates, tube-feeding methods were limited and led to inaccurate cuts. Tube marking and scratching were common, and the spinning tubes and associated noise and vibration were dangerous, especially if the tubes were bowed.

Discover How a Custom-Built Hautau Lathe Improved DOM Tube Production - Hautau. A long-held Hautau hallmark is its ability to custom-design and build tube and pipe cutting solutions to suit individual needs of specific businesses.

A perfect example is when PTC, a major Midwest producer of high-quality cold-drawn tubes needed to improve their tube cutting operations. Custom-Designed and Built Rotating-Head Cutoff Lathe Leads to Increased Production and Better Yield Because cold-drawn tubes vary in length, the business’s process couldn’t cut true random lengths. This led to wasted tube and profits. How Hautau Pipe Cutting Solutions Can Completely Change the Way You Do Business - Hautau.

For many businesses, selecting a Hautau solution for their pipe cutting needs has meant an increase in efficiency and an equally impressive increase in their bottom line.

Whether you choose from our complete line of Rotating-Head Tube Cutoff Machines or require a custom solution, Hautau engineers have established a reputation for satisfying their customers’ needs and providing ongoing expert technical support. The Industry-Changing Rotating-Head Tube Cutoff Machine. Tube cutting machine is ideal for short runs - Hautau. A fabricator of hydraulic tube assemblies needed a more efficient way to cut and chamfer tubing for crimp fittings.

Their tube saws left burrs and small shavings, and their lathe-type cutoff machines couldn’t chamfer all tube ends. As a result, tube chamfering and de-burring operations were needed. Production runs were often small, and they cut many different tube sizes, so long changeover time was also a problem. And because the tubes spin for cutting there was OD marking of the tubes, and bowed tubes created a safety hazard if they spun out of the tube guides. We combined our RC30 Rotating-Head Cutoff Machine with our indexing tube loader to load and cut tubes with no loader adjustments, plus the loader can stage several tube sizes at once to eliminate material handling delays between jobs and sizes. Unique Tube Cutting Solution Also Improves Product Tracking - Hautau. A manufacturer of heavy truck driveshafts came to Hautau with a two-pronged problem.

The cutoff machines they were using were slow and took too much time to set up.Because there are three tubes of different lengths in a typical driveshaft, they needed a better way to track each tube group throughout the assembly process. Their previous practice of relying on paperwork and manual entry meant their production runs were often slowed to a snail’s pace. Here’s How Hautau Solved Their Problems While we carry a full line of standard rotating-head cut-off machines, we often design unique solutions for individual manufacturing problems. For this client, we took the basics of our RC60 rotary-head cutoff machine – our most popular model – and added functions that would speed up the client’s turnaround time and make it easier for them to efficiently and accurately track the different tubes throughout their assembly processes. Here’s how we did it. Hautau Offers a Better Way for Conveyor Idler Rolls - Hautau. Automated conveyors are essential for manufacturers, retailers and distribution centers throughout the world.

It’s not unusual for the conveyors to literally have thousands of powered rollers and belt-driven idlers for smooth sorting and moving of products. With a traditional manufacturing method, the idlers require several steps for production. After the tube has been cut to its specific length, it’s then manually loaded onto a separate machine that will form the groves – which are crucial to advancing the product along the line. A Better, Easier, and More Efficient Approach The Hautau method, though, is anything but traditional. CC80 Double End Bore machine - Hautau.

Hautau endfinishing machines have powerful and precise servo-hydraulic tool feed to support heavy feed rates and continuous production applications. Our robust machine frame plus heavy-duty hydraulic chucking ensures you'll meet tight-tolerance requirements and produce chatter-free bevels and bores. Tube OD: 0.20 inch to 8.7 inch Wall Thickness: .03 inch to 1.0 inch Tool Feed Travel: 3 inch.

C80 8.7" Tube Beveler Machine - Hautau. C50 5" Tube Beveler machine - Hautau. Hautau endfinishing machines have powerful and precise servo-hydraulic tool feed to support heavy feed rates and continuous production applications. Our robust machine frame plus heavy-duty hydraulic chucking ensures you'll meet tight-tolerance requirements and produce chatter-free bevels and bores. Tube OD: 0.50 inch to 5.0 inch Wall Thickness: .03 inch to 1.0 inch Tool Feed Travel: 3 inch.

C30 3" Tube Beveler machine - Hautau. Tube Beveling and Chamfering Machines - Hautau. Dual Blade Shear Cutting Machine - Hautau. RC60 Rotary Cutoff Machine Advantages: The nick-and-shear tube cutoff method is a proven system for high-production cutting of thin-wall tube. Here's how it works: The tube is clamped in precise dies that conform the the profile of the tube. A scarf blade extends, cutting a small section to weaken the top of the tube.

The shear ram extends to cut the tube and eject the slug. The scarf and shear rams have high-speed hydraulic drive, with no cams or linkage to wear out. RC80-H CutOff Lathe - Hautau. What are the benefits of combining tube cutting and chamfering into one operation? If you currently saw a lot of tubes, and those tubes need to be deburred or chamfered after cutoff, you know that the extra tube handling and equipment setup can take more effort than the cutting operation. And if your production runs are short with frequent changeovers, having to setup the tube chamfering machine for each size will reduce your productivity. Our rotating-head tube cutoff lathe holds the tube stationary for cutting, then chamfers both tube ends before releasing the tube. This combines the cutting and chamfering into one operation and eliminates any secondary chamfering operations.

RC60-H Cut Off Lathe - Hautau. RC50-H 5" CutOff Lathe - Hautau. Tube Cutting Machine - Hautau. Automatic Tube Cutoff Machine - Hautau. Tube Cutting and Chamfering - Hautau. Rotary-head cutoff machine that cuts tube and chamfers in one operation. High-Speed Automatic Cutoff Lathe - Hautau. RC30 Automatic Pipe Cutoff Lathe (3.0 inch) Tube-cutoff-saw - Hautau. RC Rotating Head CutOff Machines - Hautau.