Expert Committee on Specifications for Pharmaceutical Preparations - WHO Technical Report Series, No. 863 - Thirty-fourth Report: Annex 6 - Good manufacturing practices: guidelines on the validation of manufacturing processes: 1. Types of process vali. PROCESS VALIDATION IN PHARMACEUTICAL INDUSTRY; AN OVERVIEW. Abstract Quality cannot be adequately assured by in-process and finished inspections and testing but it should be built in to the manufacturing process.

These processes should be controlled in order that the finished product meets all quality specifications Validation is one of the important steps in achieving and maintaining the quality of the final product. If each step of production process is validated we can assure that the final product is of the best quality. Validation of the individual steps of the processes is called the process validation. Different dosage forms have different validation protocols. KEY WORDS: Process validation, CGMP, GMP, Validaton protocol , SOP. Process Validation & Equipment Qualification Services. Global Regulatory Authority Websites. Asia and the Pacific Europe Middle East.

PARENTERAL DRUG ASSOCIATION POINTS TO CONSIDER: Pharmaceutical Quality Metrics Updated September 2014. Product Catalog - Parenteral Drug Association. The Changing Face of Pharmaceutical Distribution Traceability. What Do (and Will) Pharmaceutical Distributors Need to Keep Track of?

In its ERP system, IBS has some key features that aid pharmaceutical distributors in keeping track of the following information pertaining to compliance: Which innovative new product has been a game-changer this year? Tell us & win! Learn More 1. Pharmaceutical distributors must maintain the licensing information of their customers at both the federal and state levels to assure that they are permitted to sell pharmaceutical products to properly-licensed entities. 2. Pharmaceutical distributors must be able to report sales of pharmaceutical products using a common coding system. 3.

ValGenesis Inc. Successfully Completes Service Organization Controls 2 (SOC 2) Report under AT. FREMONT, Calif., May 10, 2016 /PRNewswire/ -- ValGenesis Inc., the market leader in enterprise Validation Lifecycle Management Software solutions, announced today that it has completed its Service Organization Controls 2 (SOC 2) examination under AT Section 101, Attest Engagements (AICPA, Professional Standards) for the period of January 1st 2015 through December 31st 2015 for the second consecutive year.

The SOC 2 examination is performed in accordance with AT Section 101, Attest Engagements (AICPA, Professional Standards) with completion denoting that selected ValGenesis Inc. processes, procedures and controls have been formally evaluated and tested by an independent accounting and auditing firm. The examination included the company's controls related to the Trust Services Principles and Criteria of Security, Availability, Processing, Integrity and Confidentiality. Choose your plan - Learnaboutgmp. How does the 14-day free trial work?

Try it, it’s on us. You can have unlimited access to Learnaboutgmp for 14 days, with no contracts and no credit card required. You even get free phone and email support in case you have questions about our service. Learnaboutgmp.com. BiotechNEWS & Life Sciences: Nieuws. GxP regulations - Rescop Software, Regulatory System Compliance Partners.

Compliance Actions and Activities > Enforcement Activity. Compliance Tips Archives. What does QbD mean for pharmaceutical companies?

Quality by Design (QbD) refers to a set of risk-based principles, applied to manufacturing practices in order to ensure that the development and processes yield a quality product based on solid scientific and engineering principles. For pharmaceutical companies specifically QbD principles are based on regulations that have been around for several years (since 2006), such as ICH Q8 Pharmaceutical Development and ICH Q9 for Quality Risk Management and Q10 for Quality Systems. Thus, a majority of the QbD components for process validation are not unfamiliar.

When helping to incorporate the QbD principles into our clients’ process validation practices, we notice that a lot of the pieces are already in place. It’s usually more about organization of data consumption by all stakeholders. WHO Expert Committee on Specifications for Pharmaceutical Preparations - WHO Technical Report Series, No. 863 - Thirty-fourth Report: Annex 6 - Good manufacturing practices: guidelines on the validation of manufacturing processes: 1. Types of process vali. PROCESS VALIDATION IN PHARMACEUTICAL INDUSTRY; AN OVERVIEW. Literature - Provantage® Services.

GRC Capability Model 3.0 (Red Book) - OCEG. The GRC Capability Model 3.0 (Red Book) helps GRC professionals plan, assess, and improve their GRC capabilities in order to achieve Principled Performance.

Principled Performance is the healthy and vigorous state of being that enables organizational success. It can only be achieved by integrating and aligning information and core functions, and supporting them with strong communication, effective technology, and development of the desired culture. It’s not enough to aggressively move toward established objectives. For success, we must consider the boundaries of laws, social mores, and uncertainties that arise with regard to potential risks and rewards. Nor can the management of risk, compliance, and ethical conduct be separated from the objective-seeking activity. GRC Capability Model Updates OCEG was the first to publish a GRC Capability Model (and the only one independent of a specific profession or vendor solution).

Four Components of The Model Sources For The Model Update. Archived Recordings The Hitchhiker’s Guide to 483s and Warning Letters – 2015 Archived Recording Download In this light, entertaining but rigorous Webinar by Angela Bazigos, CEO Touchstone Technologies, presenter of our other excellent webinar on writing FDA compliant SOPs, you will learn the very latest in FDA compliance trends, how to respond to an FDA 483 and warning letter, and how to prevent them from occurring at all.

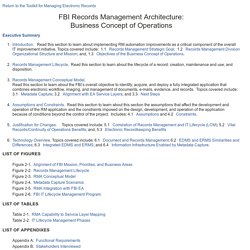

Any [...] Read More » International Society for Pharmaceutical Engineering. FBI Records Management Architecture: Business Concept of Operations. Executive Summary Introduction.

Read this section to learn about implementing RM automation improvements as a critical component of the overall IT improvement initiative. Topics covered include: 1.1 Records Management Strategic Goal; 1.2 Records Management Division Organizational Structure and Mission; and, 1.3 Objectives of the Business Concept of Operations. Records Management Lifecycle. Read this section to learn about the lifecycle of a record: creation, maintenance and use, and disposition. Top Tips for Software Validation Protocol Execution - askaboutgmp.com. What should a test protocol contain?

What is the typical content of a test protocol? Before any test execution takes place there are a number of checks you must do before entering into the world of test execution. “Fail to prepare, prepare to fail” no truer words can be spoken in relation to protocol execution. The links to success. Test Strategies – ITK Engineering. QbD for Better Method Validation and Transfer. More companies in the pharmaceutical industry today are adopting the principles of Quality by Design (QbD) for pharmaceutical development and manufacturing. Described in ICH Q8, Q9 and Q10 guidance documents, QbD enables enhanced process understanding, and a more systematic and scientific approach to development, so that better controls may be implemented.

The end goal is more robust manufacturing processes than those that typically result from traditional approaches to drug development. The QbD framework has many implications for manufacturers and regulators alike. Free Policy Management Resource: Navigating the Sarbanes-Oxley Waters. FDA Software Validation: What To Do To Validate Quality Computer Systems. The FDA (Food and Drug Administration) and IEC (International Electrotechnical Commission) requirements for validation of your manufacturing and quality system software can conjure up a lot of questions. Understanding the actual guidelines and best practices for meeting these requirements isn't always clear. Your software may be compliant, but you may not be. This article provides answers the top five most common software validation and documentation questions asked by others in FDA regulated industries and demonstrates best practices for meeting the guidelines.

What systems are considered Quality Systems? The FDA mandates that software used for the design, manufacture, packaging, labeling, storage, installation, and servicing of all finished devices intended for human use shall be validated. Your initial system assessment should provide you with the list of your systems which require validation. GAMP Standards For Validation Of Automated Systems. Strategies to validate automated systems while balancing internal and external demands By Joseph DeSpautz Business Development Asia Pacific Rockwell Automation Kenneth S.

Kovacs Life Sciences Technical Consultant Rockwell Automation Dr. Case Study: Validation Projects In China. Overview This case study details the experiences of Pharmadule Morimatsu in guiding leading Chinese manufacturers through facility investment projects aimed at achieving compliance with Chinese, US and EU Good Manufacturing Practice (cGMP) requirements. Chinese manufacturers have therefore become among the first in the world to fully embrace the work procedures outlined in ICH Q8, Q9 and Q10. Implementing these guidelines in large organisations would be a challenge with any global market. However, the Chinese manufacturing environment offers both advantages and cultural challengeswhen managing change. Introduction: Changing Chinese GMP environment. Validation Projects in China. Between 1997 and 2000 Pharmadule built a number of pharmaceutical manufacturing facilities in China for both domestic manufacturers and multi-national pharmaceutical companies, including Eli Lilly and AstraZeneca.

The multi-national companies required GMP compliance and validation services comparable to the level that exist today. The facilities delivered for Chinese manufacturers would comply with international GMP requirements; but it became evident at that time that the Chinese GMP regulation was immature in comparison with the EU regulations and guidelines. In 2011, all of this changed when China launched the new GMP regulations which elevated the requirements to a level equivalent with international cGMPs.

At about the same time, Pharmadule refocused the strategy towards the Chinese market and has since then been carrying out Validation, Quality Management Systems, GMP compliance improvement, and design projects in China. Key observations. Validation master plan ppt. The Pharmaceutical Inspection Cooperation Scheme - PIC/S - Publications. What Makes for a Good Validation Master Plan? Guidelines for Preparation of VMP (Validation Master Plan) Guidelines for Preparation of VMP (Validation Master Plan) Validation master plan ppt.

Official web site : ICH. Validation Master Plan (VMP). VMP Rationale. The Validation Master Plan (VMP) is a document that the regulatory inspectors have not mandated a format for; but have mandated a requirement for. The VMP is intended to project a picture of how your company has integrated ”current Good Manufacturing Processes” (cGMP); as promulgated in 21 CFR Part 820 & 211, into all aspects of the manufacture of a regulatory controlled product. Even although the VMP is not mandated; it inevitably will be the first document regulators will ask to review. This is because they expect this document to clearly and concisely illustrate to them how management has delegated responsibilities, designed product processes, planned resources usage and established a fully trained competent work force.

They will look for evidence to convince them that there is sufficient ongoing training to maintain these standards and sufficient auditing to prove it. In authoring the VMP extremely important commitments and decisions have to be made. Validating Electronic Spreadsheets or Automated Forms. FDA Software Validation: What To Do To Validate Quality Computer Systems. USP Reference Standards Development Process. The life of a USP Reference Standard begins with a review of the associated documentary standards (monographs and General Chapters), including those in development, to assess compendial uses. Once USP has identified the need for a new Reference Standard, it requests bulk materials from corresponding manufacturers. USP subjects the candidate materials it receives to rigorous analysis and review. Reference Standard candidates are collaboratively tested in multiple laboratories.

Digital Asset Management Software. Process Validation & Equipment Qualification Services. Buy IQOQ, FAT, PQ Templates !ValidationResources. FDA's New Process Validation Guidance: It's as easy as 1,2,3 - Express Pharma. Tech Trendz. Validation (drug manufacture) Publications - Business Decision Life Sciences. Validation and Regulatory Compliance for Life Science Professionals. Guidance Documents (Medical Devices and Radiation-Emitting Products) > Blue Book Memos - ODE Guidance Memoranda.

PE Previous Issues. Issues. IFPAC 2016 Conference Neither rain, nor sleet, nor snow could keep me from finding the lastest technology The 2016 IFPAC conference venue was a combination of a “good news/bad news” statement: the good news was that its location placed it within a short drive/Metro ride from FDA’s headquarters in Maryland. The bad news? It was held in late January…and despite protests to the contrary, it always snows in the N.