Hacking at Branches or Striking at the Root? Henry David Thoreau said “There are a thousand hacking at the branches of evil for every one striking at the root.” His statement was a commentary on the human condition but, I believe, describes quite well the state of most companies: companies launch initiatives that don’t actually attack root causes of business problems, instead their aim is on the branches — we need to pay Taiichi Ohno’s 5-Why’s a visit and remember that surgically attacking statistically validated root causes is the only way to solve problems, improve the customer experience, and improve the enterprise. Taiichi Ohno is known to have said that “having no problems is the biggest problem of all.” He viewed problems not as a negative but as a “Kaizen opportunity in disguise.”

Whenever problems arose, he encouraged his staff to investigate the problem at the source and to as “ask ‘why’ five times about every matter (src).” In a series of events, where people are involved, mistakes happen. 1. Facts Versus Data. Kanban Types and Analytical Sizing. Unlike traditional “push” systems, where material is moved downstream according to a schedule, or simply “shoved” downstream even when the downstream partner is not ready for it, a “pull” system encourages and almost forces cooperation, from a systems perspective.

“Push” also causes congestion, which grows exponentially as more items enter the queue. Aside from cooperation and coordination, a “pull” system also eliminates overproduction, underproduction, work-in-process, and inventory. One key element that encourages “pull” in a system is the Kanban. A Kanban is a low-tech, visual card that authorizes or request movement of material or process. It acts as a signaling system that notifies a supply partner that something is needed, and the amount needed. Notice that this Kanban is simple and very low-tech. Note that there are several types of Kanbans, or signaling systems, and variants also.

Again, it is very low-tech, yet it is incredibly powerful. Focus on the Customer. Jeff Bezos, during a pre-peak meeting once said to a small group of us that there will be many, many winners on the internet.

He said that some follow the close-follower mentality and those companies focus on the competition. He continued to say that Amazon has and always will be customer obsessed. He vowed that neither he nor Amazon would ever focus on the competition. He said that customer happiness is the right and only solid thing that we could ever hope to spend our time on. Focusing on the customer breeds innovation and ensures healthy direction. Often I hear people focused on the competitor.

I can think of several reasons: Creativity and Misguided Effort leads to featuritis — Featuritis is the act of too many features where a great percentage don’t fulfill a real human, customer need. I’m sure you can think of more. I definitely agree with Kathy’s curve above. One way to avoid the above result is to focus on the customer and abandon the competitor-focused strategy all-together. Managing Constraints Under Peak Volumes.

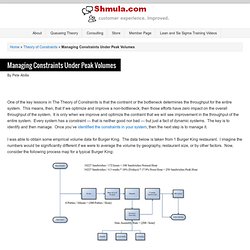

One of the key lessons in The Theory of Constraints is that the contraint or the bottleneck determines the throughput for the entire system.

This means, then, that if we optimize and improve a non-bottleneck, then those efforts have zero impact on the overall throughput of the system. It is only when we improve and optimize the contraint that we will see improvement in the throughput of the entire system. Every system has a constraint — that is neither good nor bad — but just a fact of dynamic systems. The key is to identify and then manage. Once you’ve identified the constraints in your system, then the next step is to manage it. I was able to obtain some empirical volume data for Burger King. Over the course of an average month, Burger King produces 34227 sandwiches.

Now, let’s take a look at the process map. Under normal hours, the constraint functions reasonably well. How To Manage A Constraint Under normal hours, it appears that the Assembly Step can produce at expected demand.