How to make home made paint - Robin Wood. I started playing with eco paints many years ago and tried various limewashes, milk paints etc.

The recipe which I use now we learned whilst I was teaching at the National Hancrafts school in Sweden, it is quick and very easy to make, cheap quick drying, smells nice and when fully cured washable. It is a linseed oil emulsion paint. You will need 1 whole egglinseed oil, I prefer raw cold pressed.waterjam jar with tight fitting lid. I am making this batch to paint some wooden bowls I carved a few weeks ago but it is equally good for walls or windows and doors. So here are my ingredients First crack your egg into the jar put the lid on and shake it really well. Then put the lid on and shake really well. Now add 3 egg volumes (6 half shells) of water, swirling to mix then put lid on and shake. Now I am going to add pigment, this is a ground earth pigment “ultramarinbla” that we bought in Sweden, anyone who has traveled there will have seen houses painted with it. So that is the good part.

Woodworkers Guide: Easy to build Continuous Motion Treadle Lathe. Build an 1805 Treadle Lathe. By Stephen Shepherd Stephen Shepherd is a maker of traditional pattern woodworking tools and a writer on early woodworking technique.

His passion for this subject has inspired him to design, build and develop a set of plans for a reproduction 1805 turning lathe, with a small workbench area conveniently built into the lathe bed. While it is easy to dismiss a foot-powered tool as inefficient in the modern age, foot powered lathes give you a wonderful mix of safety, control, and exercise. Turning speeds are lower, but with sharp tools you will turn as fast as with an electric lathe. The speed is infinitely variable and the lathe can even go backwards, which is a help for finishing. Part of the thrill is working on a lathe of your own construction. The Shepherd Treadle Lathe Plans include complete construction plans, a parts list, material requirements and an extensive narrative overview of the project. 8 sheets, 11" by 17" plus 4 pages of instructions. Binding: TPPublisher: Full Chisel Press. Underhill Foot-powered Lathe and Scrollsaw.

Bob Easton » Blog Archive » Treadle Lathe. Preserving history at the Kansas City Renaissance Festival A lathe, my dearest, an ole time treadle lathe.

Re-enacting at Fort Osage Missouri We looked at some pictures a while. She said “Sure, get to it … but, if you show up in one of those costumes…” These top two photos are thanks to Jerry who preserves history by working with the Institute for Historic and Educational Arts in Kansas City. It’s still too cold in the shop for epoxy based boat building, and another 5 inches of “global warming” just fell today, I’ve been considering two other woodworking paths.

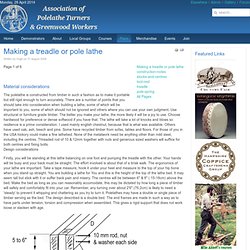

Beautiful old clocks (or replicas), complete with mechanical movements, are things I have built in the past and have considered for the future. So, let’s pursue the alternative, the lathe. Association of Greenwood Turners. Making a treadle or pole lathe. Material considerations The polelathe is constructed from timber in such a fashion as to make it portable but still rigid enough to turn accurately.

There are a number of points that you should take into consideration when building a lathe, some of which will be important to you, some of which should not be ignored and others where you can use your own judgment. Use structural or furniture grade timber. The better you make your lathe, the more likely it will be a joy to use. Choose hardwood for preference or dense softwood if you have that. The Woodwright's School - Make the Spring Pole Lathe w/ Roy.

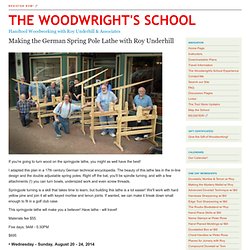

If you're going to turn wood on the springpole lathe, you might as well have the best!

I adapted this plan in a 17th century German technical encyclopedia. The beauty of this lathe lies in the in-line design and the double adjustable spring poles. The Slidy Mandrel. The Slidy Mandrel. I have just started to look into bowl turning on a pole lathe, and I have been particularly struck by the energetic nature of it all. I see the hefty logs being whirled around first one way then the other, alternately by foot pressure and spring, as the wood is pared down to reveal the (hopefully) beautiful bowl hiding away in its interior. What a waste, I have thought to myself, heaving the log round towards me, as I cut, then slowing down, stopping, and reversing its rotation to recover the treadle, only to be slowed down from reverse, stopped and set off again in its forward motion for the next cut.

Addressing this problem, I have come up with the enclosed 'invention', The Slidy Mandrel. In truth there is nothing new in all the world, and I think I take my inspiration for this from pre and post war electric clocks, that had magnetic synchronous alternating current motors. When making the spool, make sure the hole as concentric as possible through it. Pole Lathe - Sean Heilman. Robin Wood - Pole Lathe YouTube Video. Treadle Lathe by CME Handworks Review. Human Power I’m going to make an assumption here- if you read my blog then you’re probably into hand tools and if you’re into hand tools then you’re probably like me and spend some time browsing the Internet looking for things like vintage planes and hand drills, old hand saws, and treadle lathes….basically the cool old tools Roy Underhill used for all those years.

Well a few weeks before Christmas I stumbled into the e-bay store of CME Handworks Inc. in Palos Heights, IL. USA. Chris and Mary Yonker run CME Handworks where Chris manufactures beautiful hand tools. From wooden bodied scrapers and mallets to bow saws and treadle lathes. Chris has come up with a design that is both aesthetically pleasing and completely user friendly.You’ll see what I’m talking about when you visit their store.

The lathe is made from 1 3/4″ Poplar with a hard maple tool rest and Bubinga handles.