BB Fertilizer Blender-HuaQiang Heavy Industry. This series of BB fertilizer equipment is a new generation of hybrid equipment developed by our company.

BB fertilizer blender solves the impact of material characteristics, mechanical vibration, air pressure, voltage fluctuations, cold weather and other factors on the system. It has the characteristics of high accuracy, fast speed and long service life. It is a BB fertilizer (blended fertilizer) production line Ideal choice. The bb fertilizer blender through special internal xcrew mechanism and unique three dimensional structure for material mixing and output.The equipment design is novel and partical,and its feeding system does not store materials.And uniform electronic control system,manual,automatic,composite setting are the characteristics of its similar products.The equipment has the characteristics of low price,small floor space,large output and even mixing.

This machine can divided into three parts: Double Axis Mixer-HuaQiang Heavy Industry. The double axis mixer uses the synchronous rotation of two symmetrical sprial shafts to add water and agitate the powdery material such as dry ash,and uniformly humidify the dry ash power material so that the humidified material does not dry ash and does not ozze out.The purpose of the water droplets is to facilitate the transportation of humidified ash loading vechicles or transfer to other convveying equipment.It is mainly used in the occasion of humidification and loading of fly ash or similar materials in thermal power plants,mines and other industries.

When the dry powder material enters the body evenly through the feed intake through the feed intake, the power drive machinery drives the spiral spindle with multiple groups of blades to rotate, and the passive spiral shaft is driven by the meshing transmission gear to rotate the main shaft at the same speed, so that the material is stirred and pushed to the humidifier section of the tank body. 1.

Horizontal Mixer -HuaQiang Heavy Industry. This series of horizontal mixer is a new kind of mixing equipment which made by our company.

The machine has the advantages of high mixing degree and little residue, so that it is suitable for mixing the organic fertilizer and inorganic fertilizer. 1. The material is fully mixed so as to improve the mixing uniformity. Fertilizer Mixer Machines. Straw Crusher-HuaQiang Heavy Industry. The straw crusher is mainly used for chopping processing of plant straws such as crop straws and branches with a diameter of 5 cm or less, and can also be used for chopping processing of various crop straws and pastures.

The crushing machine is mainly used for chopping processing of biomass such as cotton stalks, bark, branches, corn stalks, wheat straw, straw etc. The processed products can be used for power generation, paper making, wood-based panels and refined alcohol. 1. Chain Crusher- HuaQiang Heavy Industry. The chain crusher is suitable for the crushing of the block in the production of compound fertilizer.

It is widely used in the chemical,building materials,mining and other industries. The machine uses high-strength and high-strength hard alloy chain plates with synchronous speed in the process of pulverization. The material design is reasonable,the broken material is uniform and it is not easy to stick to the wall,which is easy to clean. According to the installation form,the chain crusher is divided into two types:vertical crusher and horizontal chain crusher.The vertical chain crusher is a single rotor,and the horizontal chain crusher is a double rotor with a steel chain.One end of the chain is connected to the rotor,and the other end of the chain is provided with a ring head made of wear-resistant steel.The chain crusher is an impact crusher that pulverizes the impact of the block by a chain that rotates at a high speed.

CHARACTERISTIC 1. Half-Wet Material Crusher-HuaQiang Heavy Industry. Half-wet material crusher is a professional equipment for professional crushing high humidity and multi-fiber materials.

The half-wet material crusher uses a high -speed roating blade to pulverize the fiber with good particle size, high efficiency and high engery. The successful development of the half-wet material crusher has played an important role in shortening the production process of bio organic fertilizer and compost, it also can reduce the investment of equipment and save the operation cost. The half-wet material crusher is mostly used in the production and processing of organic fertilizer and the smashing of production and processing of organic fertilizer, and the smashing of chicken manure, humic acid and other raw materials have a good effect. Cage Crusher-HuaQiang Heavy Industry. The cage crusher is a special equipment for crushing granular urea independently researched and developed by our factory.

It consists of a host, a storage box, a cyclone unloader and a bag filter. It has the characteristics of simple structure, convenient installation and use, low noise, no pollution and long service life. It is the first choice for fertilizer production enterprises to crush granular urea. The fertilizer machine mainly used in biological organic fermentation composting,urban domestic garbage composting,grass mud carbon,rural straw garbage,industrial organic garbage,chicken manure,cow dung,sheep manure,pig manure,dusk manure and other biologicak fermentation high-humidity material crushing processing special equipment.The machine is also suitable for mining,coal metaurgical and other industries. It has played a role in grinding hard materials such as glass,ceramics,bricks and gravel of urban domestic waste organic fertilizer and achieved safe implementation. All Kinds Of Fertilizer Crusher Machine. Hydraulic-roller-granulator. Ring-die-granulator. Flat-die-granulator.

Disc Granulator for Fertilizer Production. The disc granulator is also called pan granulator.The disc granulator is reformed by our company based on the advanced technology of similar equipment at home and abroad.

Disc granulator has the advantages of uniform granulation, high granulation rate, stable operation, strong and durable equipment, long service life and so on. It is the ideal equipment selected by the majority of users. Rotary Drum Granulator, -HuaQiang Heavy Industry. Rotary drum granulator is the main equipment of compound fertilizer production line.

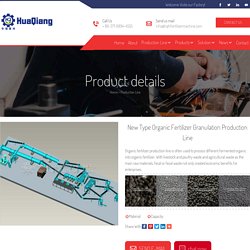

It is the latest generation of rotary drum granulator developed by absorbing and digesting advanced technologies at home and abroad and combining with specific working conditions of relevant industries in China. It is suitable for granulation technology of various materials. His working principle is through a certain amount of water or steam, the basic fertilizer after humidification fully chemical reaction in the cylinder. New Type Organic Fertilizer Granulation Production Line. Organic fertilizer production line is often used to process different fermented organic into organic fertilizer.

With livestock and poultry waste and agricultural waste as the main raw materials, fecal or fecal waste not only created economic benefits for enterprises, but also made great contributions to human environmental engineering. In the organic fertilizer production line,every fertilizer machine play a different role. Process flow: The process flow of the organic fertilizer production line can be divided into raw material pretreatment, aerobic fermentation, and fertilizer granulation processing. Two-in-one Granulation Bio-organic Fertilizer Production Line. The design of the bio organic fertilizer production line is designed according to two production principles, one is the principle of organic fertilizer fermentation, and the other is the principle of organic fertilizer granulation. Bio organic fertilizer is a kind of fertilizer which has the effect of microbial fertilizer and organic fertilizer, which is composed of specific functional microorganisms and organic materials mainly from animal and plant residues (such as livestock and poultry manure, crop straw, etc.) after harmless treatment and decomposition.

Its production line technology is similar to that of organic fertilizer, which requires fermentation, crushing, mixing, granulation, drying, cooling, screening, coating and packaging. Fertilizer Machine & Production Line Manufacturer. Fertilizer Granulator and Fertilizer Granulation Process manufacturers-Zhengzhou Huaqiang. Why does the output of organic fertilizer granulator not go up sometimes? For the same organic fertilizer granulator, the reason why the test machine is not the same as the actual particle shape lies in the materials used.

During the test run, the manufacturer will give the user some materials prepared in advance, whether the density or humidity of the materials are just right. Therefore, when pressing the organic fertilizer granules, the molding rate is very high, and the particles are beautiful, but the users go back In the future, the materials used are not as perfect as when the machine was tested, resulting in different results. In fact, this problem is caused by the unqualified product quality of some manufacturers, and the compatibility of equipment is not good, which leads to this situation. As we all know, the molding rate of organic fertilizer granulator directly reflects the quality of organic fertilizer equipment, and also determines the profits of customers. Fermentation production process of chicken manure organic fertilizer pellets. The design of the fertilizer granulation process of chicken manure organic fertilizer pellet fermentation includes: 1.

High-efficiency compound strain and its propagation technology; 2. Advanced raw material blending technology and biological fermentation system; 3. New Type Organic Fertilizer Granulator-HuaQiang Heavy Industry. The new type organic fertilizer granulator is our new patened machine that our company and the Agricultural Machinery Research Institute.This fertilizer granulator machine can not only granulate a variety of organic matters, especially for coarse fiber materials which are difficult to granulation by conventional equipment, such as crop straw, wine residue, mushroom residue, drug residue, animal manure, etc., after fermentation, granulation can be achieved, and the granulation effect of humic acid and municipal sludge is also very good.

The granules are solid and can be sieved after granulation to reduce the energy consumption of drying. The moisture content of raw materials can be about 20% - 40%. 5. The organic matter after fermentation does not need to be dried, and the moisture content of the raw materials can be 20-40. Structural composition: Biofertilizer production, organic fertilizer production, organic fertilizer making, fertilizer production line.

Double Roller Press Granulator -HuaQiang Heavy Industry. The double roller press granulator is a compound fertilizer granulator which has been researched and produced by our company for many years. It is a new designed fertilizer equipment by our company based on the double roller fertilizer granulator machine. The machine is widely used for the fertilizer processing industry, feed production industry and chemical industry to granulate, produce and process powdered objects. It has advanced technology,reasonable design,compact structure,low engery consumption and the corresponding equipment. Different Types Fertilizer Granulator Machine.