Texas Flange

Texas Flange has served the petrochemical, process, and waterworks industries for over 3 decades. For more information, contact us today!

CreativeLive Student Profile. Why Do Forging Flanges Need Heat Treatment? If you want to know why do forging flanges need heat treatment, you must first get an understanding of the meaning behind forgings.

Forging is the use of a hand hammer, pressure equipment, or forging hammer on the mold on the heating of the metal blank force so that metal materials under the condition of non-separation plastic deformation obtain performance, size, and properties meet the requirements of parts. Need of heat treatment for the forged flange The main purpose is to refine the coarse grains, eliminate the residual stress and work hardening, reduce the hardness, improve the cutting performance, prevent the white spots while forging, and make sure about the required machinery and metal structure.

Now, below are details about the heat treatment: Normalizing If you want to forge flange connections, heat treatment is the first step. If you normalize the temperature range that is usually between 760֯C and 950֯C, depending on the phase transition point of different component content. 5 Qualities of Excelent Pipe Flanges. Five Key benefits of Flanges. Flanges are helpful to connect pumps, valves, pipes, and other parts to form a piping system.

Flanges are typically welded or thread screwed to connect. The use of flanges allows a person for maintenance and easy repair of the pipe system. Various Kinds Of Titanium Flanges: texasflange — LiveJournal. Titanium flanges are one of the materials that help to prevent seawater corrosion.

The flanges are lightweight, corrosion-resistant, and strong. It is used for different applications like gas industry, petrochemical equipment, glasses, military, oil industry, medical equipment, and much more. One of the known things about flanges is their joining methods after welding. It is widely helpful when the joints need dismantling. Custom Pipe Flange. Does Texas Flange do Custom Flanges?

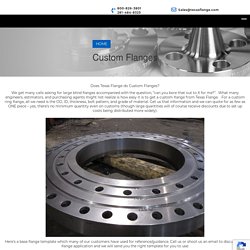

We get many calls asking for large blind flanges accompanied with the question, “can you bore that out to X for me?”. What many engineers, estimators, and purchasing agents might not realize is how easy it is to get a custom flange from Texas Flange. For a custom ring flange, all we need is the OD, ID, thickness, bolt pattern, and grade of material. Get us that information and we can quote for as few as ONE piece – yes, there’s no minimum quantity even on customs (though large quantities will of course receive discounts due to set up costs being distributed more widely). Here’s a base flange template which many of our customers have used for reference/guidance. Discover the World’s Top Designers & Creative Professionals.

A blind flange is a solid steel piece with n… 5 Qualities of Excellent Pipe Flanges. Pipe flanges offer a reliable way to connect pipe systems with various valves, equipment, and other components of virtually any processing system, flanges are the second most used joining method after welding.

Pipe flange is an essential part of any pipeline system and needs to be high-quality to meet the demanding environment these forged components live in. Pipe flanges come with excellent qualities. Here are 5 of them: Customizable Pipe flanges are customizable as per the needs. Available in different sizes and shapes Pipe flanges are helpful in many industries in different ways. Durable Flanges are used under some of the most difficult conditions, like gases, high-pressure liquids, high-temperature with these being highly corrosive at times, pipe flanges must be durable.

Lightweight Heavy pipe flanges could indeed make transport difficult. 5 Qualities of Excellent Pipe Flanges. Purpose of the Flange Bolt Rules in ASME VIII and ASME III: texasflange — LiveJournal. ASME VIII Div.1 Appendix 2 and ASME III Div.1 Appendix XI provide “Rules for Bolted Flange Connections” with ring-type gaskets.

It is one of the rules applicable to the calculation of the minimum required bolt area. The two force components Wm1 and Wm2 The rules are intended to provide bolts with sufficient pre-tension in achieving two objectives: Providing a compressive force Wm2 needs to seat the gasket during the initial assembly of the flange joint. Counter a pressure-induced force Wm1 that tends to pry open the flange in operation. How to Remove Exhaust Flange Bolts Easily. Although not in our supply chain, we have had a few questions regarding other types of flange bolting and installation.

Here is a basic guide to exhaust flange assembly. Exhaust flanges consist of a pair of metal sections that join your exhaust pipe together. They are helpful in conjunction with an exhaust set of bolts and gaskets. The usual options of exhaust flanges are the 3 bolt or 2 bolt types. Usually, m10 with the 2 bolt option is helpful, and an m8 bolt for the 3 bolt. Slip On Pipe Flange. Slip on flanges are a popular type of pipe flange designed to accept pipe into the bore/center of the flange for welding around both the Outer Diameter (OD) of the pipe and on the interior side of the connection.

You may recognize them: The slip-on flange is a simple and excellent alternative to a weld neck as it does not have a weld bevel, and therefore allows the pipe to be adjusted in length relative to its position of the flange. The bore of the slip on will give ample amount of space for the matching pipe. This allows for enough working space for the welder and fabricator to make the connection. This flange type is extremely common in lower pressure applications. Slip on flanges are more commonly found in lower pressure assemblies and become less utilized when a higher stress service calls for a superior connection to the piping assembly. Pinterest. Weld Neck Flanges vs Slip On Flanges - Download - 4shared - texas flange. Texas Flange (texasflange)

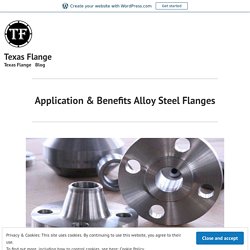

Application & Benefits Alloy Steel Flanges – Texas Flange. The formation of alloy steel can happen by adding metals and non-metals to carbon steel.

Corrosion resistance ability, strength, and durability are some of the features of Alloy steel flanges that customers appreciate. Alloy steel flanges are useful in steel pipelines. Weld neck flanges are included in some of them that can perform well under harsh conditions of high pressure, high temperature, or sub-zero temperature. Steel alloy flanges include chromium, molybdenum, copper, and many other pure metals. The flanges provide long life, outstanding finish, and high strength with the help of these metals. The manufactured flanges help customers with functionality and additional advantages to meet their demands and requirements.

The high-grade flanges have various features like anti-slip flooring, weather-resistant, anti-corrosive, dimensionally stable, longer service life, rust-free, lightweight size, high reliability, and much more. Like this: Like Loading... Weld Neck Flanges vs Slip On Flanges. Texas Flange. Advantage Of Stainless Steel Super Duplex Flanges. What Is The Scope And Purpose Of Installing Flange Guards - Download - 4shared - texas flange. Specification and Types of Carbon Steel Flanges. The manufacturing of carbon steel pipes happens by using various techniques that produce a pipe with various characteristics.

The carbon content present in the carbon steel pipe can be up to 2.1 percent of the weight of the total alloys. An increase in the carbon percentage in the alloy helps to increase the tensile strength and hardness of the metal. The black carbon steel jacketed pipe would lose its ductile properties, even with a rise in the percentage of carbon. About Carbon Steel Flanges. Contact Us - Texas Flange. Stainless Steel Flanges - Download - 4shared - texas flange. Installing Flange Guards and its importance: texasflange — LiveJournal. Flange guards act as protective shields that are useful in preventing the leakage of the various harmful chemicals from the joints of the flanges, valves, pipelines, etc.

The chemical industries work at risk each day. Many pharmaceuticals and chemical industries work with different types like caustics, chlorine, alkaline, acid, or other harmful chemicals that are highly reactive with natural substances. It may also cause damage to the machine and man and may result in explosions. When Do We Use Slip-On Flange, A Weld Neck Flange Or A Lap Joint Flange. There are few types of flanges, but the most used types by ASME B16.5 are weld neck, slip-on, and lap joint flange. Weld Neck Flange These are easy to recognize at the long tapered hub. It goes gradually over to the thickness of the wall from a fitting or pipe. The long tapered hub provides an essential reinforcement for use in several applications that involve elevated, sub-zero temperatures or high pressure.

The smooth transition from fitting or pipe wall thickness to flange thickness gets affected by the taper and is extremely beneficial under the conditions of repeated bending caused by the line expansion or other variable forces. Pin on Infographics and Banners. What Is The Scope And Purpose Of Installing Flange Guards? How to Avoid Corrosion on Flanges. Flanges can go through two types of corrosion in their lifetime: Crevice and Pitting. Pitting Corrosion occurs on the face of the flange and often appears in groups or clusters. This kind of corrosion causes small pits or cavities to form on the surface of the material. Pitting corrosion is best prevented by proper alloy selection. A very high rate of Crevice Corrosion occurs when there is a build-up of concentrated substance between two adjoining flanges. It is the type of corrosion that can be very damaging as it is not easy to inspect the areas where it is occurring.

Cad / 3D Flange Drawings - Texas Flange. Hydraulic Flanges and Components: texasflange — LiveJournal. Square flanges are made of stainless steel or steel and are useful in a wide range of systems with standard pipes in oil fields, pipe projects, offshore environments, water systems, and more. They are frequently useful in hydraulic systems to connect pipes to components or make strong pipe-to-pipe connections.

As you might expect based on the name of the part, these flanges feature a square shape. Why Choose Lap Joint Flanges or Rolled Angle Rings – Texas Flange. Rolled Angle rings are famously known as Vanstone Rolled Angle rings or Vanstone rings. They offer comparable benefits to lap joint stub ends with installation requirements and similar designs. However, the subtle difference will often make one preferable over the other in most cases. It is essential to note that Rolled Angle Rings are not the ones you can register for fittings. You can install butt-weld rolled angle rings which are similar to the lap joint stub ends.

Benefits and Features of Stainless Steel Super Duplex Flanges. Duplex is a Fe-Ni-Cr alloy that has a two-phase ferritic-austenitic stainless-steel microstructure when it is at room temperature. Combining austenitic grades and ferritic comes with an advantage. Weld Neck Flanges vs Slip On Flanges. High Yield Flanges - Download - 4shared - texas flange. Main Features Of Pipe Flanges: texasflange — LiveJournal. Pipe flanges offer a reliable way to connect pipe systems with various valves, equipment, and other components of virtually any processing system, flanges are the second most used joining method after welding. Pipe flange is an essential part of any pipeline system and needs to be high-quality to meet the demanding environment these forged components live in. Why Do Hydraulic Lines Use Square Flanges? – Texas Flange.

Square flanges are made of stainless steel or steel and are useful in a wide range of systems with standard pipes in oil fields, pipe projects, offshore environments, water systems, and more. Pin on Infographics. Weld Neck Flanges vs Slip On Flanges. What are the Uses of Alloy 20 Pipe. Alloy 20 is a chromium-iron-nickel-based, austenitic alloy that comes with excellent corrosion resistance in chemical environments.

It contains sulfuric acid and many aggressive media well. The alloy is stabilized with niobium that helps it to resist intergranular corrosion. Alloy 20 can help provide potential cost savings compared to the higher nickel-based alloys as it outperforms standard stainless steel. Flange Basics - Texas Flange. Weld Neck Flanges vs. Slip On Flanges – Texas Flange. What are the Uses of Alloy 20 Pipe. How to Use a Spectacle Blind Flange?: texasflange — LiveJournal. What Is The Scope And Purpose Of Installing Flange Guards - Download - 4shared - texas flange. This is the most common grade of s…

8 Materials for Constructing Flanges. When it comes to flanges, the purpose is simple – they help to reinforce the ring, collar, rim, or ridge on an object like pipe, beam, column, and so on. Tips To Stepping Into Flanges : texasflange — LiveJournal. Texasflange's profile on ThemeForest. How to Order Custom Flanges? A flange industry must focus on specific flanges like ASME, ANSI, AWWA, and industry-standard flanges that specialize in customer order flanges. With a wide range of systems, shops, and industries dependent upon high-performance flanges, custom pipe flanges are essential to get the job done correctly.

Modified and custom flanges for specialty projects may offer the performance expectations, inspection requirements, same quality. They may also offer material, specific sizes, or fit for a unique application. What are the Different Types of Titanium Flanges? Tips to Select the Right Flange Gasket. What Are Different Grades of Carbon Steel Flanges? Texas Flange. What Are The Different Types Of Titanium Flanges - Download - 4shared - texas flange. Stepping Into Flanges. How To Make Best Choice Of Carbon Steel Fittings: texasflange — LiveJournal. We offer higher-yield variants of carbo… 8 Materials For Constructing Flanges. Difference Between ANSI and ASME. Texas Flange's TED Recommendations. Boiler Code Flanges - Texas Flange. Purpose of the Flange Bolt Rules in ASME VIII and ASME III. Things to Know Before Buying Flanges. Texas Flange (@texasflange)

Learn About Types of Pipe Flanges: texasflange — LiveJournal. Pointers to the Make Best Choice of Carbon Steel Fittings. ANSI B16.1 Industry Standard Archives - Texas Flange. Pin on Flanges. 8 Materials for Constructing Flanges. Texas flange (texasflange) How To Choose The Right Pipe Flanges: texasflange — LiveJournal. Effect of Temperature on Bolted Flange Assemblies. The Benefits and Uses of Stainless Steel Flanges. ANSI B16.47 Note - Texas Flange. Tips to Select the Right Flange Gasket – Texas Flange. ANSI B16.47 Series B Flanges - Texas Flange. Understanding Lap Joint Flanges : texasflange — LiveJournal. 8 Materials for Constructing Flanges. Tips To Use Steel Pipe Flange For The First Time.

Socket Weld Flanges. Effect of Temperature on Bolted Flange Assemblies. How Are Flange Bolts Tightened. How to Find the Right Flange Dimensions: texasflange — LiveJournal. Texasflanges's Profile. Tips To Use Steel Pipe Flange For The First Time. DOMESTIC & IMPORT - Texas Flange. Use of ASME B16.5 Standards for Flange Pressure Ratings. ANSI B16.47 Series A Flanges - Texas Flange. Guide To Select Various Types of Flanges : texasflange — LiveJournal. Texas Flange. Guidelines for Selection of Various Types of Flanges. Stainless Steel Flanges. Guidelines for Selection of Various Types of Flanges. Finding the Right Pipe Flange for Your Project. Tips To Use Steel Pipe Flange For The First Time. ANSI B16.5 – ½” – 24” Forged Flanges Weight Chart - Texas Flange.

Mistakes You Don’t Want To Make With Flange Fittings. About – Texas Flanges – Medium. Blind Flange - Download - 4shared - texas flange.