Werkstattprojekt Linienhof. 150791-3250-plasma-table-build-2. CNC Plasma. Since we will be working primarily with 1/4 inch steel on a 74ft boat, we selected a Hypertherm Powermax1000 with a 50 ft umbilical between the machine and the hand torch; part number 083179.

The price was just over $2,400 with shipping from www.bakersgas.com in early 2008. We don't need 50 ft of umbilical for the CNC table, but it will come in very handy when working out on the boat. Plasma torches require lots of dry air, or they will not cut cleanly and they will burn up the expensive consumables faster. We already had 5 HP compressor capable the required of 6.7 cfm at 90 psi, however we added a low cost "3-in-1 Refrigerated Air Dryer" unit from Harbor Freight for $300. China Kugelumlaufspindel - Seite 2. Dimensionierung Kugelumlaufspindel. Estlcam.de 2D / 3D CAM Software und CNC Steuerung... Help for buyers of a CNC machine work center for stone. CNC Fräsmaschine, Fräse, Portalfräse, CNC router, milling -NEU-

Hinweis: Ihr Gebot ist bindend.

Wenn Sie auf Gebot bestätigen klicken und Höchstbietender sind, gehen Sie einen rechtsverbindlichen Vertrag mit dem Verkäufer ein. Die vollständige Artikelbeschreibung finden Sie unten. Bieten Gebot überprüfen und bestätigen. Router Bits and EndMills: Pictures, Descriptions, and Uses. CAD & CNC. MadVac CNC - home made 4'x8' cnc precision gantry router.

The design objectives for MadVac CNC: General purpose 4 axis (two Z axis) production machine capable of 2D and 3D routing of material within 7" x 52" x 99" envelope Milling wood, plywood, plastics, all grades of aluminum and softer metals 3D mold making Repeatability and precision of movement to 0.0005" and better Heavy, relatively rigid structure Easily accessible open table Small footprint base Modular design for disassembly, moving and reassembly Repeatable and accurate assembly Upgradeable to servo motors Compact Y gantry with Z and W axis both of which can work in 52" x 99" envelope Mobile controller console that can move to any point around the machine Complete mechanical, electronics, software system under $16,000.

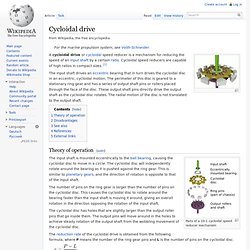

A few random thoughts and reflections about the project: The research, design and planning of every component, materials and aspect of this machine took about one full year and the construction itself started in Jan 2004 and was 95% finished in July 2004. DIY CNC CO2 Laser Site. Cycloidal drive. A cycloidal drive or cycloidal speed reducer is a mechanism for reducing the speed of an input shaft by a certain ratio.

Cycloidal speed reducers are capable of high ratios in compact sizes. [1] Theory of operation[edit] Parts of a 10:1 cycloidal speed reducer mechanism The input shaft is mounted eccentrically to the ball bearing, causing the cycloidal disc to move in a circle. The cycloidal disc will independently rotate around the bearing as it is pushed against the ring gear. Startseite - SK-CNC - individuelle CNC-Portalfräsmaschinen. CNC 2050mm verfahrweg Antriebsfrage? Hack a Day — Fresh hacks every day. How-to Video: Adjusting Pre-load on Low Profile Redi-Rail. Index. Untitled. William L's Scratch Built CNC Machine Here is a scratch built machine (from the plans or book) that exhibits great workmanship, but more importantly, how some of the construction of the CNC machine was done.

William L. used sound techniques to make sure the machine would be constructed as intended, knowing that some of the machine would have various size differences within the sub assemblies that would make some of the measurements within the plans not work. Contraptor. CNC Plasma Table Idea Notebook. Boring head. Betrachtungen zur Leistung von Schrittmotoren « SCHRITTMOTOR-BLOG DIPL.-ING. THORSTEN OSTERMANN SCHRITTMOTOR-BLOG DIPL.-ING. THORSTEN OSTERMANN. Da mich immer wieder Anfragen zur Auslegung von Netzteilen für Schrittmotor-Steuerungen erreichen, habe ich vor einigen Jahren angefangen, mich etwas intensiver mit dem Thema auseinander zu setzen.

Eine Anfrage bei verschiedenen Herstellern von Schrittmotoren, wie denn die Leistungsaufnahme von Schrittmotor und –Endstufe zu berechnen sei, stieß überwiegend auf Achselzucken. Die einzigen Aussagen zum Thema waren, dass so etwas normalerweise nicht berechnet, sondern in der jeweiligen Anwendung gemessen würde. Das mag für Serienanwendungen sicherlich die einfachste Lösung sein.

Für den Sondermaschinenbauer, der nur eine Anlage baut, ist diese Herangehensweise aber nicht befriedigend. Und selbst für die Serienanwendung ergibt sich der Nachteil, dass man zunächst den Aufbau eines Prototypen abwarten muss. Eine häufig getroffene Annahme von meinen Kunden zur Netzteilauslegung sieht etwa so aus: Strom pro Phase * 2 Phasen pro Motor * Anzahl der Motoren = Gesamtstrom. Schritt. How To Decrease Noise on Your Stepper Motor Driver. Die Seite rund um die eigene CNC Fräse. Fachbegriffe. Kostenfreie CAD Bauteilebibliothek mit 2D Zeichnungen und 3D Modelle. 10Werkzeughalter.pdf. Zwei kleine Universalfrässpindeln. CNC Mill Servo Spindle Conversion. One of the last major modifications to my mill that I have wanted to make is replacing the 3 phase spindle motor, vfd, and vari-speed drive with a servo motor.

Several years ago I had picked up a 3.5kw Mitsubishi MR-J2S series servo motor when one popped up on ebay for a couple hundred bucks. The plan was I would use that motor to replace the 2kw servo motor in the 10EE with this once I found a drive for it and then move the 2kw motor to the mill. Well, in the two years that it took for the correct drive to show up on ebay I got that injection molding press and used the 5kw motor and drive in there to replace the 2kw in the lathe. Meine Eigenbau Portalfräse aus Holz. CNC Projects. Success! Mini Machining Center under Mach3 control - Video link. Photointeruptors come in a lot of different flavors, some costing under US$ 1.00Some have lenses over the LED and some do not.

Some have wires attached and some have only bare pins. Some have polycarb housings and some use much cheaper plastic. Some are rated for vibration and some not . . etc. etc. In order, I have had lots of false signals from stray light and dust with the un-lensed parts, pins break off very easily on the parts with bare pins sticking out (in fairness, these are meant to be mounted on a PCB, not have wires hanging off them), plastic housings that dissolve seemingly in anything except distilled water, and finally, some just litterally fall apart. The 4th axis was the 'acid test' that killed a number of these parts, some of which were actually working fine as homing switches.

After the above experience with various recommended products, I have settled on the following rather expensive unit US$ 7.25 approx. Technologies content from Machine Design. Backlash, a clearance between mating gear teeth, is built into speed reducers to let the gears mesh without binding and to provide space for a film of lubricating oil between the teeth.

This prevents overheating and tooth damage. On the other hand, the same clearance causes lost motion between reducer input and output shafts, making it difficult to achieve accurate positioning in equipment such as instruments, machine tools, and robots. For these applications, there are three basic ways to reduce or eliminate backlash: precision gears, modified gears, and special designs that use components other than gears. 4th Axis for the IH CNC Mill. Servo Motors and Spindle Motors. Peters CNCECKE - User Davide.