Redutores. Fuso. Pololu Micro Serial Servo Controller (assembled) Discontinuation notice: This product has been replaced by our newer Maestro USB servo controllers, which are better in almost every way.

These older servo controllers are now only available by large-volume special order. Please contact us for more information. The Pololu micro serial servo controller (SSC) is a very compact solution for controlling up to eight radio control (RC) servos from a computer or microcontroller. The controller measures just 0.91" x 0.91", yet it is one of the most full-featured servo controllers available. Each servo speed and range can be controlled independently, the baud rate is detected automatically over a 1200-38400 bps range, and multiple units can be daisy-chained on one serial line to control up to 128 servos. The micro serial servo controller is available in two configurations: fully assembled with all connector pins, as shown in the main product pictures, and as a partial kit. This servo controller supports two separate communication protocols.

Kenshi — Brushless / Stepper / Servo Motors and Custom Assemblies. An unparalleled approach to motor design and manufacturing What distinguishes Shinano Kenshi Corporation isn’t one attribute over another, but the total approach to motor design and manufacturing. We meet every job, every opportunity, and every challenge with a total solutions methodology. That approach, combined with SKC technology and engineering skills, allows us to develop and build a complete solution – allowing our customers to focus on what they do best. The resources and people to meet any challenge With modern and highly capitalized facilities in Asia, Europe, and North America, we meet challenges other companies can’t even consider.

Pittman. Action Technology. Carter Motor Company - Manufacturers of High Quality Universal, Shunt, PMDC, 3.25" PMDC, 2.5" PMDC, 56 Frame, Gearmotors, Converters, and Tachometers. Série TH - Taco Gerador 0 - 10 V ou 4 ... 20 mA. Pololu High-Power Motor Driver 18v15. This discrete MOSFET H-bridge motor driver enables bidirectional control of one high-power DC brushed motor.

The little 1.3×0.8-inch board supports a wide 5.5 to 30 V voltage range and is efficient enough to deliver a continuous 15 A without a heat sink. Overview The Pololu high-power motor driver is a discrete MOSFET H-bridge designed to drive large DC brushed motors. The H-bridge is made up of one N-channel MOSFET per leg, and most of the board’s performance is determined by these MOSFETs (the rest of the board contains the circuitry to take user inputs and control the MOSFETs).

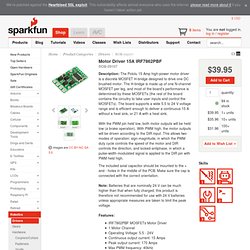

The MOSFET datasheet is available under the “Resources” tab. Note: batteries that are nominally 24 V can be much higher than that when fully charged; this product is therefore not recommended for use with 24 V batteries unless appropriate measures are taken to limit the peak voltage. Using the Motor Driver. Electronics - Motor Driver 15A IRF7862PBF. Description: The Pololu 15 Amp high-power motor driver is a discrete MOSFET H-bridge designed to drive one DC brushed motor.

The H-bridge is made up of one N-channel MOSFET per leg, and most of the board’s performance is determined by these MOSFETs (the rest of the board contains the circuitry to take user inputs and control the MOSFETs). The board supports a wide 5.5 to 24 V voltage range and is efficient enough to deliver a continuous 15 A without a heat sink, or 21 A with a heat sink. With the PWM pin held low, both motor outputs will be held low (a brake operation).

With PWM high, the motor outputs will be driven according to the DIR input. This allows two modes of operation: sign-magnitude, in which the PWM duty cycle controls the speed of the motor and DIR controls the direction, and locked-antiphase, in which a pulse-width-modulated signal is applied to the DIR pin with PWM held high. The included axial capacitor should be mounted to the + and - holes in the middle of the PCB.