Felted Signal Processing. Softcircuitsaturdays.com. Neoprene pressure sensor matrix. Four separate pressure sensors not only give feedback about where I’m pressing, but also how hard.

>> Pressure Sensor Matrix Instructable The sensitivity is ideal for finger pressure. Though it is not linear, it is stable. Very sensitive to light touch and then it takes a lot of pressure to reach the minimum resistance. The inside looks just like the fabric pressure sensors, except each stitch is connected to a separate conductive fabric tab. The downside is that separate tabs and connections to these tabs take up a lot of space, especially if you want to achieve a tight matrix of sensors. The Instructable covers two slightly different versions of the pressure sensor matrix. Videos. Felted Crochet Stretch Sensor. Sensors come in many forms, you can buy them already manufactured, or make them yourself.

The latter is my favorite for many reasons. This sensor is meant to be integrated in to wearable technology projects as an alternative to buying manufactured sensors which are made of rubber, metals, plastics and ceramics. My experience with a manufactured stretch sensor hasn't been good. It is one made of rubber with crimped metal hooks at each end. It broke easily and did not hold any properties found in materials that a wearable tech piece would mainly be constructed of; fabrics, thread and so forth. I've been experimenting with different ways of making soft sensors, particularly ones that utilize felting techniques. This sensor is crocheted in a tube, it can be crocheted in a strip and other shapes.

This technique is a starting point and meant to be ran with. Electronic Crafts. Crocheted Stretch Sensor — Soft Circuit. Zipper Slider. By using high-resistance conductive thread instead of conductive fabric, you can make a slider (potentiometer) with zippers.

Unlike zipper switch, this sensor gives analog values instead of “ON/OFF”. Resistive thread 66 Yarn 22+3ply 110 PET (4k ohm/20cm) is stitched on one side of the zipper using sewing machine. The thread is used as a top thread on the machine. To achieve the good connection to the zipper head, I had to go over the stitch many times with sewing machine. The Lame Life Saver stitch is applied on the other side of the zipper. the end of the both stitches are connected to conductive fabric where you measure the resistance between. Related Work Joo Youn Paek posted a really nice report of her construction of an analog zipper sensor using resistors sewn in series with multiple contacts back to the zipper: >> She used this technique in the Zipper Orchestra project: >>

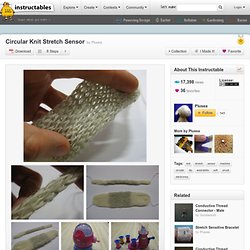

Circular Knit Stretch Sensor. Use a circular knitting machine to knit a stretch sensor with regular and conductive yarns in five minutes!

The values of the sensor range from roughly 2.5 Mega Ohm when relaxed, to 1 Kilo Ohm when fully stretched. The stretch sensing is actually due to the structure of the conductive yarn which is made up of lots of short steel fibers mixed with polyester. Even without knitting the yarn into a structure you can use it as a stretch sensor by simply pulling it taught or relaxing it.

But the yarn is not very strong and easy to tear. The knit structure allows you to accumulate more yarn and thus more resistance in less length and also by combining the conductive yarn with regular yarn you can gauge the sensitivity of the sensor by choosing a thicker or thinner yarn - thicker yarn gets more in the way of the conductive yarn making extra contact through the knitted loop structure. Buy a circular knit stretch sensor on Etsy: narrow >> wide >> Leah buechley - LilyPad Arduino - build - accelerometer shirt. DIY smart materials.