How To Open A Can Without A Can Opener. Quick & Easy Homestead Uses For Plastic Bottles (PET) In the not too distant past, you would buy milk, sodas, etc. in glass bottles which you would return to the store to be sterilized and used again.

Now, with our disposable culture, plastic bottles have replaced this system and have consequently become one of the many banes of the landfills. We need to rectify this wasteful and eco-nomically expensive practice. The current popular solution to the problem is recycling. However, recycling requires additional energy to process the material into something usable, not to mention the fact that the process itself can have harmful side effects.

Oil Press. By Jeff Cox -- from Organic Gardening, April 1979, Rodale Press IN 2,500 SQUARE FEET, a family of four can grow each year enough sunflower seed to produce three gallons of homemade vegetable oil suitable for salads or cooking and 20 pounds of nutritious, dehulled seed -- with enough broken seeds left over to feed a winter's worth of birds.The problem, heretofore, with sunflower seeds was the difficulty of dehulling them at home, and the lack of a device for expressing oil from the seeds.

About six months ago, we decided to change all that. The job was to find out who makes a sunflower seed dehuller or to devise one if none were manufactured. And to either locate a home-scale oilseed press or devise one. No mean task.Our researches took us from North Dakota -- hub of commercial sunflower activity in the nation -- to a search of the files in the U.S. Patent Office, with stops in between. Tools Required 1. DIY Crampons Give Feet Traction In Ice & Snow.

How To Sharpen Tools: The Family Handyman. Sharpening your tools Years ago, I drove by a storefront with a hand-painted plywood sign.

It read “Tool Sharpening.” Curious, I gathered a boxful of dull old handsaws and circular saw blades in my garage and carried them up to the store with the hope of getting them sharpened. An Easier Way To Chop Wood: Leveraxe Vipukirves 3. An Ax to Grind: A Practical Ax Manual, 9923-2823-MTDC, Getting the Hang of It (continued) Sharpening "Putting your nose to the grindstone" implies tedious, repetitious, and unending work. You will find that sharpening a dull or abused ax is indeed tedious and repetitious, but to do it right you have to do it slowly (Figure 62). Along the way, you'll learn the value of patience, and appreciate the differences in steel tempering and ax quality as you sharpen different axes. Wildflower Seed Processor / Leaf Shredder. Honey Extractor. Got Bee's?

Country Living Grain Mill Review. Rating: 6.8/ 10 (33 votes cast) Country Living Hand Grain Mill is one of the must have appliances for hand grain milling. Buy Country Living Hand Grain Mill on Amazon.com If you are looking for a short-term mill, the Countr Living Grain Mill shouldn’t be your choice because it has been designed to last a lifetime. It is a grain mill that can be passed down from one generation to another in near-perfect condition as if it was bought directly from the manufacturer. This explains the reason why the manufacturer is so confident in the grain mill to provide a Lifetime limited warranty. It features double industrial sealed bearings, carbon steel grinding plates, stainless steel shaft, and has a solid I-beam construction made of cast aircraft aluminum. Some of the Notable features include: How To Build A Cider Press - DIY.

Related Content Cider Press Plans Want fresh cider?

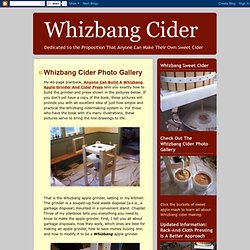

Make your own cider press using these free plans. Click on the corresponding thumbnails in the Image Gallery (accessible on Page 1 of this article) for referenced figures and diagrams. Whizbang Cider: Whizbang Cider Photo Gallery. My 46-page planbook, Anyone Can Build A Whizbang Apple Grinder And Cider Press tells you exactly how to build the grinder and press shown in the pictures below.

If you don't yet have a copy of the book, these pictures will provide you with an excellent idea of just how simple and practical the Whizbang cidermaking system is. For those who have the book with it's many illustrations, these pictures serve to bring the line drawings to life. Dust Goggles: How To Make Your Own. How to make Dust Goggles Tim Elverston design and process © This somewhat instructional page was made by Tim Elverston .

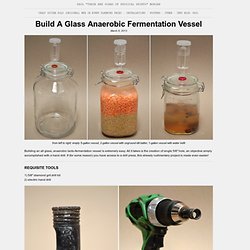

This is our studio blog and this is our main gig, repairing kites. DIY Anaerobic Glass Fermentation Vessel. Build A Glass Anaerobic Fermentation Vessel March 6, 2013 from left to right: empty 5-gallon vessel, 2-gallon vessel with unground idli batter, 1-gallon vessel with water kefir Building an all glass, anaerobic lacto-fermentation vessel is extremely easy.

All it takes is the creation of single 5/8″ hole, an objective simply accomplished with a hand drill. Handy Farm Devices And How To Make Them. Machete Or Knife Handle Made From Old Tires. Old Sewing Machine Maintenance. According to the old Singer parts lists, that big spokey wheel on the end of your vintage Singer is the balance wheel.

1,000's Of Homemade Tools. Antique Farm Tools - Introduction (home-page) How To Clean A Rusty Table Saw. How to Resurface A Very Rusty Tablesaw.