International Waterless Printing Association - Home. Climatecalc.eu. About Intergraf. Silgan. (주)일석. (주)삼원특수지 - 자연을 담은 종이, 환경을 가꾸는 디자人. Innovative Packaging Solutions. SVELON® - ACTEGA. The Innovation Power Source. How are plastics made? Forty years ago, anything made of plastic was considered "cheap.

" Plastic. Household items made of various types of plastic IUPAC definition Generic term used in the case of polymeric material that may contain other substances to improve performance and/or reduce costs.

Bioplastic. Bioplastics are plastics derived from renewable biomass sources, such as vegetable fats and oils, corn starch, pea starch[1] or microbiota.[2] Common plastics, such as fossil-fuel plastics, are derived from petroleum; these plastics rely more on fossil fuels and produce more greenhouse gas.

Some, but not all, bioplastics are designed to biodegrade. Biodegradable bioplastics can break down in either anaerobic or aerobic environments, depending on how they are manufactured. There is a variety of materials that bioplastics can be composed of, including: starches, cellulose, or other biopolymers. Some common applications of bioplastics are packaging materials, dining utensils, food packaging, and insulation.[3] IUPAC definition. (사)한국바이오소재패키징협회. 한국바이오플라스틱협회. (USA) Biopreffered. 社団法人日本有機資源協会. 日本バイオプラスチック協会(Japan BioPlastics Association:JBPA) Home - VINÇOTTE - OK compost - Global Solutions Provider. Polylactic acid. Poly(lactic acid) or polylactide (PLA) is a thermoplastic aliphatic polyester derived from renewable resources, such as corn starch (in the United States), tapioca roots, chips or starch (mostly in Asia), or sugarcane (in the rest of the world).

In 2010, PLA had the second highest consumption volume of any bioplastic of the world.[3] The name "poly(lactic acid)" does not comply with IUPAC standard nomenclature, and is potentially ambiguous or confusing, because PLA is not a polyacid (polyelectrolyte), but rather a polyester.[4] Production[edit] There are several industrial routes to usable (i.e. high molecular weight) PLA. 네이버 백과사전. 에틸렌의 중합으로 생기는 사슬 모양의 고분자 화합물이다.

중합법에 따라 여러 가지가 생성되는데, 밀도에 따라 저밀도 폴리에틸렌과 고밀도 폴리에틸렌으로 구별된다. 저밀도 폴리에틸렌은 각종 병이나 냉장고의 제빙용 상자 등의 원료로 쓰인다. 폴리에틸렌의 종류 석유의 원유를 분류(分溜)하여 나프타 부분(100∼200℃ 유출부분)을 분리시키고, 이것을 분해시켜 약 25% 에틸렌을 분취(分取)한다. 이 에틸렌을 중합시켜서 다음과 같은 식을 가지는 폴리에틸렌을 만든다(때로는 가지가 있는 경우도 있다). 중합방법에 따라 여러 종류의 폴리에틸렌이 생기는데, [표]와 같이 밀도에 따라서 대별할 수 있다. 현재는 A류에 해당하는 저밀도 폴리에틸렌(연질 폴리에틸렌)과 C류에 해당하는 고밀도 폴리에틸렌(경질 폴리에틸렌)이 주요 제품인데, 저밀도 폴리에틸렌이 많이 제조된다. 밀도 0.91 정도이며, 가지가 있기 때문에 분자 배열이 충분하지 않고 결정화된 부분이 65% 정도이기 때문에 말랑말랑해져서 잘 늘어나며, 인장강도는 약간 작지만 내충격성은 크다. 고밀도 폴리에틸렌은 이른바 치글러나타촉매(사염화타이타늄과 삼에틸알루미늄으로 이루어지는 착염촉매)를 사용하여 약 70℃, 10atm에서 에틸렌을 중합시킨다. 이밖에 중압중합법(中壓重合法)으로 만들어지는 중압 폴리에틸렌이 있는데, 중압중합법에는 필립스법과 스탠더드법이 있다. 또 초고압법이라고 하여 3,000atm을 사용하는 방법도 있는데, 이들은 모두 고밀도 폴리에틸렌을 생산한다. 폴리에틸렌. 위키백과, 우리 모두의 백과사전.

Polyethylene. 폴리에틸렌[ polyethylene (PE)]의 성질 요약은 여기를! The Plastics Distributor and Fabricator Magazine - plastics industry news. Thermoforming Process. Thermoforming describes the process of heating a thermoplastic sheet to its softening point, stretching it over or into a single-sided mold, and holding it in place while it cools and solidifies into the desired shape.

The thermoplastic sheet is clamped into a holding device and heated by an oven using either convection or radiant heat until it is softened. Casting Mold. There is more than one type of casting mold that is used in metal casting.

Each of these different types of molds is used by one or more methods of metal casting. This combination of molds and methods allows for a variety of casting sizes, quantities and properties. Graphite mold Aluminum centrifugal casting often uses graphite molds and cores. The process also uses rapid cooling resulting in a casting with qualities not reproduced by other methods.Sand mold This type of casting mold is created of pressed dry or green sand that is contained in a flask or box. PostList. Resin identification code. Sorted household plastic waiting to be hauled away for reprocessing.

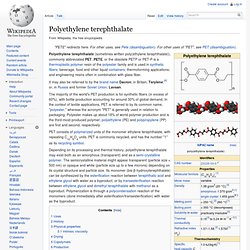

Polyethylene terephthalate. Polyethylene terephthalate (sometimes written poly(ethylene terephthalate)), commonly abbreviated PET, PETE, or the obsolete PETP or PET-P is a thermoplastic polymer resin of the polyester family and is used in synthetic fibers; beverage, food and other liquid containers; thermoforming applications; and engineering resins often in combination with glass fiber.

It may also be referred to by the brand name Dacron; in Britain, Terylene;[4] or, in Russia and former Soviet Union, Lavsan. The majority of the world's PET production is for synthetic fibers (in excess of 60%), with bottle production accounting for around 30% of global demand. In the context of textile applications, PET is referred to by its common name, "polyester," whereas the acronym "PET" is generally used in relation to packaging. Dimethyl terephthalate CAS (120-61-6) sc-239783. DB. GrainPro, Inc. Safe Storage Systems - Storing the Future. Paper.

Different typologies of paper Paper is a thin material produced by pressing together moist fibers, typically cellulose pulp derived from wood, rags or grasses, and drying them into flexible sheets.

Paper is a versatile material with many uses. [덕천판지]Global Print & Packs. Book papers, specialty papers, engineered paper products home. Package testing. Military shipping container being drop tested. KCL : 한국건설생활환경시험연구원. 포장재질.포장방법검사 검사신청. ASTM-D3078 - ASTM International (ASTM) - Medical Package Testing. Overview: The ASTM-D3078 is the standard test method for determination of gross leaks in flexible packaging containing a headspace gas by bubble emission. The test is conducted by submerging the test specimen in the immersion fluid within the confines of a vacuum chamber. If bubbles or seepage of fluid within specimen attributable to a leak are observed, then the specimen fails the test. Apparatus & Materials: Tailim Packaging. Samhwa.co. Glasslock.co.