Creep and Creep Failures. David N.

French, Sc. D.President of David N. French, Inc., Metallurgists, Northborough, MA July 1991 Category: Operations Summary: The following article is a part of National Board Classic Series and it was published in the National Board BULLETIN. (4 printed pages) What is creep? The end of useful service life of the high-temperature components in a boiler (the superheater and reheater tubes and headers, for example) is usually a failure by a creep or stress-rupture mechanism. However, regardless of the cause, the failure will exhibit the characteristics of a creep or stress rupture. Figure 1. At elevated temperatures and stresses, much less than the high-temperature yield stress, metals undergo permanent plastic deformation called creep.

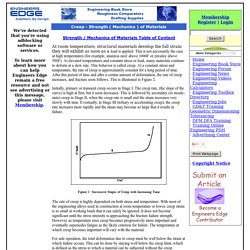

An initial steep rate that is at least partly of elastic origin, from point "0" to point "A" in Figure 1. The first two stages will not leave any microstructural evidence of creep damage. Creep failures are characterized by: Creep & Stress Rupture. Creep - Strength (Mechanics) of Materials. At room temperature, structural materials develop the full strain they will exhibit as soon as a load is applied.

This is not necessarily the case at high temperatures (for example, stainless steel above 1000F or zircaloy above 500F). At elevated temperatures and constant stress or load, many materials continue to deform at a slow rate. This behavior is called creep. At a constant stress and temperature, the rate of creep is approximately constant for a long period of time. After this period of time and after a certain amount of deformation, the rate of creep increases, and fracture soon follows. Initially, primary or transient creep occurs in Stage I. The rate of creep is highly dependent on both stress and temperature. For safe operation, the total deformation due to creep must be well below the strain at which failure occurs. We've detected that you're using adblocking software or services. MaterialsCreep. Materials Science in the Candy Store, and other Polymer Science Activities and Understandings for the High School. Science Science is the study of the how, what and why something happens.

It presupposes that there is some need to answer a question through both observing phenomena and manipulating variables. Science has no morals, instead it works from the standpoint of amorality, having no judgements to make, only conclusions based on presuppositions and then testing out variables under strict controls, sometimes just to "see" what occurs. Polymer science is the study and manipulation of molecules that are repetitions of smaller particles - the "mer" or unit, and "poly" meaning many.

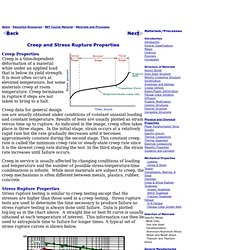

Thus, if we think of polystyrene, it is a combination of many styrene units combined together. Research by scientists have led to many new products for the consumer, however, the pure or basic research scientist is usually only interested in the reactions or experiments done. Materials Science Engineering Engineering, by its very nature, is the art of taking the scientific discoveries to the consumer. Module Overview. Creep & Stress Rupture. Creep and Stress Rupture Properties Creep Properties Creep is a time-dependent deformation of a material while under an applied load that is below its yield strength.

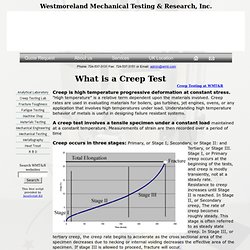

It is most often occurs at elevated temperature, but some materials creep at room temperature. Creep terminates in rupture if steps are not taken to bring to a halt. Creep data for general design use are usually obtained under conditions of constant uniaxial loading and constant temperature. Results of tests are usually plotted as strain versus time up to rupture. What is a Creep Test? Creep is high temperature progressive deformation at constant stress.

"High temperature" is a relative term dependent upon the materials involved. Creep rates are used in evaluating materials for boilers, gas turbines, jet engines, ovens, or any application that involves high temperatures under load. Understanding high temperature behavior of metals is useful in designing failure resistant systems. A creep test involves a tensile specimen under a constant load maintained at a constant temperature. Measurements of strain are then recorded over a period of time Creep occurs in three stages: Primary, or Stage I; Secondary, or Stage II: and. Radiohead - Creep. Creep and creep testing - Job knowledge 81. Job Knowledge The use of metals at high temperatures introduces the possibility of failure in service by a mechanism known as creep.

As the name suggests this is a slow failure mechanism that may occur in a material exposed for a protracted length of time to a load below its elastic limit (see Connect article No. 69), the material increasing in length in the direction of the applied stress. At ambient temperature with most materials this deformation is so slow that it is not significant, although the effect of low temperature creep can be seen in the lead on church roofs and in medieval glazing, where both materials have slumped under the force of gravity. For most purposes such movements are of little or no importance.

Increasing the temperature, however, increases the rate of deformation at the applied load and it is vitally important to know the speed of deformation at a given load and temperature if components are to be safely designed for high temperature service.