Designer 3D Prints Amazing Hand-Crank Fan in One Piece. One of the most intriguing aspects of following the 3D printing space is that I have the opportunity to see all sorts of new, incredible creations come about which previously could not even be imagined possible with 3D printing just a couple years ago.

The 3D printing space is evolving, and it’s happening at a rapid pace. With all of the new types of hardware, software, and materials being introduced on a daily basis, it makes you wonder just how hot this industry will be in the coming years. One designer, named Rob Drummond, fortunately has a way to cools things off if they become too hot. “A few years ago, I was interested in pushing the limits of my experience and knowledge of SLS printing,” Drummond tells 3DPrint.com. Autodesk Begins Taking Orders for Their Ember 3D Printer.

HP’s bold plan to become the first mainstream 3D printing company. HP’s vision to merge the digital and physical worlds — “Blended Reality” — could help it become the world’s first mainstream 3D printing company.

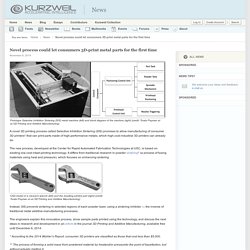

(Evan Agostini/AP) It’s a problem faced by every market leader: What do you do when your core products are showing signs of being disrupted by new technologies and nimbler competitors? You can either let someone else disrupt you, or you can disrupt your own business model. HP has apparently chosen the latter option, rolling out two innovative new products as part of a strategic vision (“Blended Reality”) to transform the company into the first mainstream 3D printing company. “Blended Reality” describes the new ecosystem that HP is creating to blend together the physical and digital worlds. Novel process could let consumers 3D-print metal parts for the first time. Prototype Selective Inhibition Sintering (SIS) metal machine (left) and block diagram of the machine (right) (credit: Torabi Payman et al./3D Printing and Additive Manufacturing) A novel 3D printing process called Selective Inhibition Sintering (SIS) promises to allow manufacturing of consumer 3D printers* that can print parts made of high-performance metals, which high-cost industrial 3D printers can already do.

The new process, developed at the Center for Rapid Automated Fabrication Technologies at USC, is based on existing low-cost inkjet printing technology. It differs from traditional research in powder sintering* (a process of fusing materials using heat and pressure), which focuses on enhancing sintering. FABtotum Personal Fabricator. We also believe in the future of personal fabrication as an inspiration for an international, open and cooperative society.

As an Open Source project, FABtotum needs the help of the very people that can understand the consequences of technologically-improved social cooperation, just like any crowdfunding supporter. Funds will be used to start-up the production process and R&D for product and production engineering, allowing us to ship FABtotum in approximately 8 months.

Known risks are:Higher production prices due to few units sold, increasing the number of components we have to preorder, reducing our resources. System integrations (especially software/electronics) might require more time than expected. Delivery: digital delivery on your Indiegogo account email. International delivery included. Coupon delivery: digital delivery on your indiegogo account email. Please note: All Coupon codes are not cumulative and will expire if not redeemed before October 1, 2014 -I’m a backer. The Zeus Is A 3D Printer, Scanner, And Teleportation Machine All In One. The future, as they say, is already here, but it’s just not very evenly distributed.

To wit: the Zeus, a 3D printer that can scan and copy objects and, using the Internet, “fax” objects to other printers. That’s right – it’s the first 3D all-in-one. Created by AIO Robotics, the $2,499 printer has a build area of 8 by 6 by 5.7 inches and can scan objects up to five inches high. Smallest, Most Precise 3D Printing Pen Yet Nearing Entry to Market. Typically, if you want to sketch out a design, it just sits there on paper.

However, a new product is about to hit the market that will bring doodles and drawings to life: a 3D printer pen. A Kickstarter campaign is currently ongoing to bring the LIX 3D pen to the market this fall. The LIX 3D pen isn’t an entirely novel idea, but 3D printer pens are relatively new. They basically work like little hot glue guns that warm up colored plastic sticks and extrude them out. While the plastic is coming out, the user just moves the pen to create a particular design.

Image credit: LIX Last spring, 3Doodle became the first 3D pen offered to the public and is still currently fulfilling orders from its wildly successful Kickstarter campaign. In comparison, the LIX 3D pen weighs 40 grams (1.4 ounces) and is 164 mm long by 12 mm wide. The fashion industry can also put this pen to work, as the plastic can be integrated into clothing or be used to make accessories and jewelry.

Home Metal 3D Printer: The Mini Metal Maker. New giant 3D printer can build a house in 24 hours. Scientists claim to have developed a revolutionary new giant 3D concrete printer that can build a 2,500-square-foot house in just 24 hours.

The 3D printer, developed by Professor Behrokh Khoshnevis from the University of Southern California, could be used to build a whole house, layer by layer, in a single day. The giant robot replaces construction workers with a nozzle on a gantry, which squirts out concrete and can quickly build a home based on a computer pattern, MSN News reported. It is "basically scaling up 3D printing to the scale of building," said Khoshnevis. 'Contour Crafting' is a layered fabrication technology and has great potential for automating the construction of whole structures as well as sub-components, according to the project website.