Builders: Boot-strappable Open Laser Cutter. Hi folks, I thought I'd take a second to make a quick post about a bootstrappable open laser cutter design that I've been working on.

I know I haven't posted relating to the Open Selective Laser Sintering (SLS) Project much after the Reciprocating Laser Cutter. Much of my lack of work on the project was due to our local hackerspace moving over the course of several months (when I had to help construct the new space), before quickly having to finish my PhD and begin a postdoc. I love having access to a laser cutter. One can construct rather large items fairly quickly, and the materials available (like acrylic) mean that not only will one's creations be structurally sound, but they'll often look wonderful too.

When the laser arrived, I ended up realizing just how big the tube is. Home Built CNC Laser Build Log. Home Built 40W CNC Laser Project Overview Note: This design has been superceded by the 2.x Laser.

There is a blog post on it, information on the wiki and a lot of discussion on the forum. Laser Cutter DIY - Tetalab. Pendant 2 jours, nous avons assemblé les pièces que Lionel avait apporté, et les parties de scanners qui se trouvaient dans le container, afin de monter un laser cutter DIY basé sur le design de Groover: Pocket Laser Engraver Pour ce projet, nous avons: 1 Arduino Duemilanove2 structure de scanner récupérée au fil des mois2 controlleurs moteur EasyDriver, disponibles chez Sparkfun1 Power ScrewShield Snootlab (ou autre proto-board pour le cablage)1 diode laser IR récupérée dans un graveur DVD1 laser de chez DealExtreme, dans lequel mettre la diode laser IR, qui contient une lentille et le driver de la diode (courant constant) Le plotter est composé de 2 structure de scanner sur lesquelles on a laissé les moteurs (ainsi tout est déjà aligné et bien stable).

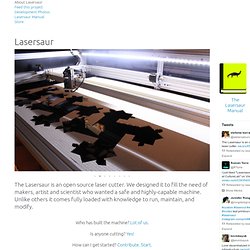

L'axe X est le scanner du bas, nous avons choisi le scanner le plus stable pour cet axe (un gros scanner Agfa) et rajouté des pieds afin de niveler la structure horizontalement. Une fois connecté à l'arduino, vous pouvez: Lasersaur. Lasersaur The Lasersaur is an open source laser cutter.

We designed it to fill the need of makers, artist and scientist who wanted a safe and highly-capable machine. Unlike others it comes fully loaded with knowledge to run, maintain, and modify. Since its conception, Nortd Labs and the Lasersaur community has generated knowledge to develop a comprehensive system. We have specifically focused on laser cutting, software, and making the building process repeatable. How can you Contribute? Unlike software, hardware RD is costly even when living off of Ramen. Short on cash? $32 Beta Access: Support the project and get full access to design documents, community (mailing list), and software before the project goes fully open source.

$(any) Project Support: Simply want to support the project? We Accept Bitcoin! Credits Mad props to reprap.org, www.cnczone.com, arduino.cc, grbl, buildlog.org, and their giants' shoulders. Lasersaur: Open Source Laser Cutter by nortd » Updates. The good news is, we are now onto v0.3 of the Lasersaur system!

Check out the video! (and for ongoing build documentation) There is still some waiting for parts (specifically limit switch mounts, laser tube mounts, paneling etc) until what we hope will be the final testing before we can finalize the alpha kits! The goal is for the kits to be shipped to backers by mid-March and have the community up and running sometime around then as well.

The time then, is near! Now, some details and versions updates: First and most exciting perhaps is the actual laser has arrived! We decided to do our initial testing with a 40W tube, it will cut enough to tell whats working and not, but isn’t strong enough to burn down to our neighbors below. As you can see, it sort of looks like a transparent missile, so we are going to give China cred for that one: Also, in order to speed up testing we went ahead and ordered a water chiller. We also updated the idler shafts. Next you can see the new v0.3 drive shaft. Voir le sujet - lasersaur projet opensource de construction d'un lasercutter. Sam's Laser FAQ - Home-Built Nitrogen (N2) Laser. Back to Home-Built Nitrogen (N2) Laser Sub-Table of Contents .

Other Examples of Home-Built N2 Lasers Well, this one probably wasn't actually built at a home but close enough. :) The following is from a paper by Bruno Godard entitled: "A Very Simple High Power Large Efficiency N2 Laser", May 1973. The copy I have is from the "Laboratoires De Marcoussis, Centre De Recherches De La Compagnie Generale d'Electricit, Departement Recherches Physiques de Base, Section Sources d'Ondes Cohrentes", 91460 - Marcoussis France.

Thanks to Jon Singer ( jon@joss.com ) for locating this paper. Note that I don't know of anyone duplicating these results. Notable physical features of this design include: A parabolic shape for the primary capacitor electrode (the one with the spark gap) to create a linear excitation of the laser channel that moves with the speed of light. A longer cavity than that of the SciAm laser (almost double).

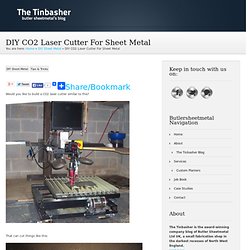

(From: Jon Singer, of the Joss Research Institute.) Overall - M. Power supply - L. CNCzone.com-Machinist Community Forums - Welcome Page. DIY CO2 Laser Cutter For Sheet Metal. Would you like to build a CO2 laser cutter similar to this?

That can cut things like this: Instructables has an exceptional step-by-step guide as to how to go about it. As the introduction states: The general idea of this CO2 laser system is that a beam is directed down to a part for cutting. The part sits on a computer controlled platform which moves the piece around the stationary laser beam.

There are pictures a plenty, videos of it in action, a block diagram pdf and seven extensive pages of instructions on how to build one. Well, the site is called Instructables.