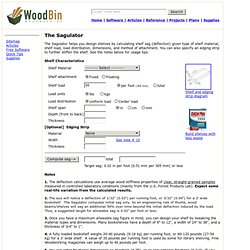

How to Build these Woodworking Projects, Lots of good Ideas! Vintage Projects and Building Plans. KoolBIrd. Woodworking for engineers. The Sagulator - Shelf Sag Calculator. The Sagulator helps you design shelves by calculating shelf sag (deflection) given type of shelf material, shelf load, load distribution, dimensions, and method of attachment.

You can also specify an edging strip to further stiffen the shelf. See the notes below for usage tips. Notes 1. The deflection calculations use average wood stiffness properties of clear, straight-grained samples measured in controlled laboratory conditions (mainly from the U.S. 2. 3. 4. 5. 6. 7. 8. 9. 10. Tips for Managing Shelf Sag If shelf span is reduced by one-fifth, stiffness is roughly doubled (deflection is halved). Credits and References The Sagulator employs established engineering formulas for calculating beam deflection. Special thanks to Steve Stephenson for providing initial formulas and Jeff Bratt for his very helpful input (including the spiffy shelf diagram), and derivation of formulae for handling an edging strip.

Making a Small Wooden Box #1: Getting Started - by Don. I blogged a couple of weeks ago about what I should charge for a small box I was asked to make.

I thought that those of you who haven’t delved into the wonderful world of box making might like to journey along with me as I make this commissioned box. I was given the outside dimension for the box, as the owner intends to place it in a chest of drawers, so it must fit the size constraints of the drawer. The box will be 95mm high x 360mm wide x 240mm deep (approximately 3.75” x 14” x 9.5”). I have selected a wood I’ve had in my stock for some time. I’m not absolutely certain, but I believe it to be Northern Queensland Lacy Oak. The joinery will be miters with splines. Below I’ve milled the box walls to approximately 1/2” thickness, cut the pieces to length and mitered the ends.

Here I’m clamping the Victoria Ash trim to the lid frames. After the glue has dried, I plane with a small Stanley adjustable mouth block plane and finish with a scraper. -- CanuckDon "I just love small wooden boxes! " Do-It-101.com, Carpentry for Boys Table of Contents. Table of Contents A Typical Work Bench.

Acute. Sharp, to the point. Adjuster. A tool which measures distances and relative spaces. Finger Joint Jewelry Box - Jeff Greef Woodworking. Jeff Greef Woodworking Cut out list- Finger Joint Jewelry Box 2- 1/2 x 3 5/8 x 12 lower front and rear 2- 1/2 x 3 5/8 x 8 lower sides 2- 1/2 x 1 7/8 x 12 lid front and rear 2- 1/2 x 1 7/8 x 8 lid sides 2- 1/2 x 7 1/4 x 11 1/4 top and bottom 2- 1/8 x 1 3/8 x 7 1/4 lower dividers 2- 1/2 x 7/8 x 10 1/2 shelf front and rear 2- 1/2 x 7/8 x 5 1/2 shelf sides 1- 1/8 x 5 1/2 x 10 1/2 shelf bottom 4- 1/8 x 7/8 x 4 3/4 shelf dividers 2- 1/8 x 7/8 x 7 5/8 shelf dividers 1- 1/2 x 2 x 4 1/2 ring insert 2- 1/4 x 1/2 x 1 shelf hinge spacers 2- 1/4 x 3/8 x 3 1/2 levers Feet, at whatever chosen configuration 1/8" dowels, 1/4" dowels Resources For Building A Finger Joint Jewelry Box Lathes | Clamps | Drill Bits | Drill Presses | Glue | Miter Gauges | Routers | Router Bits | Router Tables | Table Saws The first step on this project, after cutting out all your parts according to the list, is to cut all the finger joints.

Router Workshop: boxjoints. Use a 1/2” 14 degree dovetail bit in a table mounted router.

Bolt the 3/8” spacer fence over the table with a 1/2” space between the fence and the bit. This space is measured from the bottom of the dovetail profile, not the tip. Set the height of the bit at approximately 5/16 so the slot will fit over the spacer fence. It will be necessary to drill another hole for the dovetail bit operation (predrilled in the Router Workshop Table Top). Remove the bolt in the end of the spacer fence closest to the operator. Again, check your fit by clamping two pieces of 3/8" thick material together (make sure the bottoms are flush) and cutting dovetails in one end.

Once the fit is correct, you are now ready to cut dovetail splices. Lift the groove over the spacer fence and cut the next groove. Downloadable wooden toy plans and woodworking projects. Woodworks Library.