Home - 6ixSigma.org. Six Sigma Coaching Institute. Statistics: Properties of the Normal Curve - CliffsNotes. Six Sigma History" Motorola claims that its people invented Six Sigma, but the principles behind the methodology date back to 1809.

That's when Carl Gauss, a German mathematician, published "Theoria Motus Corporum Arithmeticae. " In this book, Gauss introduced the concept of the bell curve, a shape that can often represent the variation that occurs in a controlled process. Before we dive into the statistics of the bell curve, let's talk a moment about variation. Variation is defined as deviation from expectation. Every process and activity has inherent variation. When data is collected from a typical process and plotted on an x-y axis, the nature of the variation starts to become clear. If you were to plot the data in a bar chart that depicts the frequency of occurrence for each employee start time, you would end up with the chart below. The histogram provides a visual representation of your variation. Now let's look at a bell curve without any underlying data. Biography: Dr. Mikel Harry. Read Dr.

Mikel Harry’s responses to common questions about Six Sigma. His biography is below: Ph.D., Arizona State University, 1984 M.A., Ball State University, 1981 B.S., Ball State University, 1973. Six Sigma - The Evolution of Six Sigma. Before, January 15, 1987, Six Sigma was solely a statistical term.

Since then, the Six Sigma crusade, which began at Motorola, has spread to other companies who are continually striving for excellence. While it is progressing, it has extended and evolved from a problem-solving technique to a quality strategy and ultimately into a sophisticated quality philosophy. However, this unique philosophy only became well known after GE’s Jack Welch made it a central focus of his business strategy in 1995. Today, Six Sigma is the fastest growing business management system in industry . To elaborate the evolution of Six Sigma, one Six Sigma authority has to be introduced: Mikel Harry, who is called the “godfather” of Six Sigma and is acknowledged as the leading authority on theory and practice.

In 1984, after Harry was awarded a doctorate from Arizona State University, he joined Motorola where he worked with Bill Smith, a veteran engineer who was in Mikel Harry's words, “the father of Six Sigma”. Six Sigma History - Page 1. Six Sigma - What is Six Sigma - History and Development of the Six Sigma Strategy< Six Sigma Process Improvement Throughout the history of business, there have been many systems used for process improvement.

Process improvement is the methods used to increase overall … What is Six Sigma? Every business and industry relies on strategic management to help fulfill a business’ goals and objectives. Strategic management oversees a company’s … Six Sigma Calculation And Calculators. Six Sigma Calculator: Six sigma metrics comprises of the different types of measurements that are applied in six sigma methodology.

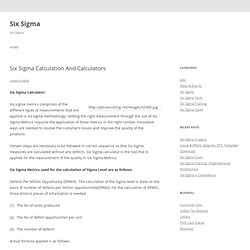

Getting the right measurement through the use of Six Sigma Metrics requires the application of these metrics in the right context. Innovative ways are needed to resolve the customer’s issues and improve the quality of the products. Certain steps are necessary to be followed in correct sequence so that Six Sigma measures are calculated without any defects. Process Sigma Level and DPMO calculator. Enter your Defects per One Million Opportunities (DPMO) to compute Sigma level.

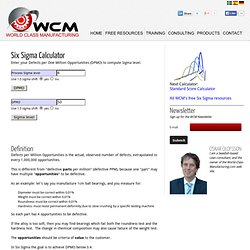

Definition Defects per Million Opportunities is the actual, observed number of defects, extrapolated to every 1,000,000 opportunities. This is different from "defective parts per million" (defective PPM), because one "part" may have multiple "opportunities" to be defective. As an example: let's say you manufacture 1cm ball bearings, and you measure for: Diameter must be correct within 0.01% Weight must be correct within 0.01% Roundness must be correct within 0.01% Hardness: must resist permanent deformity due to slow crushing by a specific testing machine So each part has 4 opportunities to be defective. If the alloy is too soft, then you may find bearings which fail both the roundness test and the hardness test. The opportunities should be criteria of value to the customer.

iSixSigma. Six Sigma. The common Six Sigma symbol Six Sigma is a set of techniques and tools for process improvement.

It was developed by Motorola in 1986.[1][2] Jack Welch made it central to his business strategy at General Electric in 1995.[3] Today, it is used in many industrial sectors.[4] Six Sigma seeks to improve the quality of process outputs by identifying and removing the causes of defects (errors) and minimizing variability in manufacturing and business processes. It uses a set of quality management methods, mainly empirical, statistical methods, and creates a special infrastructure of people within the organization ("Champions", "Black Belts", "Green Belts", "Yellow Belts", etc.) who are experts in these methods. Each Six Sigma project carried out within an organization follows a defined sequence of steps and has quantified value targets, for example: reduce process cycle time, reduce pollution, reduce costs, increase customer satisfaction, and increase profits.

Doctrine[edit] Methodologies[edit] Inc. - Motorola University.