Koneistus Ohjeita T 10. MAKRO OHJELMOINNIN KOULUTUSMATERIAALI FANUC OHJAUKSELLE. Flat Metal Doesn't Always Mean Stress Relieved Metal - Fabricating and Metalworking. Whether it's coming from a service center or an upstream process, most sheet or plate will contain residual stress, as shown in left sample, compared to same material (on right) after processing in a parts leveler.

The servo-hydraulic leveler adjusts its force instantly to compensate for the varying cross section of parts with large cutouts and perforations, or shapes such as triangles and circles. Comparison of leveled and unleveled sheet metal after robotic welding. A free-standing servo-hydraulic leveler integrates easily into fab shop workflow to supply stress-free parts for bending, assembly or welding. Transforming the Way Material is Cut - Fabricating and Metalworking. A review of some of the newest laser cutting systems, laser marking equipment, and related accessories and services now on the market.

The Laser Next from Prima Power offers the best dynamic performance of any 3D laser on the market, with 208 m/minute trajectory speed and 2.1 g acceleration. The JENOPTIK-VOTAN BIM laser machine is primarily used in the automotive industry to cut highly complex 3D car body parts and structural parts as well as hydroformed tubes, e.g. for exhaust systems, precisely and quickly. Manufacturers can also benefit greatly from its dynamic capability laser cut contours and functional holes in white goods, tanks and containers. As a highly productive, universal machine, the TruLaser 5030 fiber from TRUMPF is able to process complex contours and thin sheets while keeping the cost per part to a minimum.

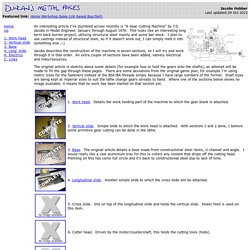

Machining. Jakobs gear hobbing machine. Työstöarvot. Jacobs Gear Hobber. An interesting article I've stumbled across recently is "A Gear Cutting Machine" by T.D.

Jacobs in Model Engineer, January through August 1976. This looks like an interesting long term back burner project, utilising structural steel mainly and some bar stock. CNC Programming Basics, Tutorials & Example Codes - Helman CNC.