Joints for Delta Printer. Delta Math / Inverse Kinematic The predicted nozzle position is given by the software (slicer, G-code) in Cartesian coordinates (X, Y, Z).

The firmware has to calculate the position of the 3 vertical carriages so that the nozzle moves to the predicted position. Delta robot kinematics - Tutorials. The delta robot consists of two platforms: the upper one (1) with three motors (3) mounted on it, and smaller one (8) with an end effector (9).

The platforms are connected through three arms with parallelograms, the parallelograms restrain the orientation of the lower platform to be parallel to the working surface (table, conveyor belt and so on). The motors (3) set the position of the arms (4) and, thereby, the XYZ-position of the end effector, while the fourth motor (11) is used for rotation of the end effector. You can find more detailed description of delta robot design in the corresponding Wikipedia article. The core advantage of delta robots is speed. When typical robot arm has to move not only payload, but also all servos in each joint, the only moving part of delta robot is its frame, which is usually made of lightweight composite materials. To be more formal, let's look at the kinematic scheme of delta robot. First tests and Calibration - Repetier Firmware. I originally wrote this post, and geared it toward the firmware I was using at the time, Marlin.

I then tried to edit the post and added Repetier firmware (FW will be use for firmware for the rest of the post) notes. User feedback says it would be better to have one for , and one for Repetier FW. Open your host software and configure your port. Arduino creates a com (communications) port and that's what you'll want to use. You can leave the port and the baud at auto and let the software auto-detect these. In addition, you need to tell Repetier-host to home to X=0, Y=0, and Z=MAX (click the Printer Shape photo to zoom in). Click the Connect button and it should turn green. Check end stops Before you click home, (the 12V power should be off or you can click the "Turn Motors Off button or send M84 gcode command) manually move your effector down until all three max end stops are not touching. Bouwverslag van de Hephaestus Rostock 3D printer - Deel 2 - FiXeL's blogje - Tweakblogs - Tweakers.

Michiels Blog - Tweakers. Bouwverslag van de Hephaestus Rostock 3D printer - FiXeL's blogje - Tweakblogs - Tweakers. 42BYGHW811 NEMA-17 Bipolar 48mm Stepper , from Phidgets for €16.44. Torque Conversions: Convert Newton Meters to Newton Centimeters nm to n-cm, Convert to Dyne-centimeter, Convert to Kilogram meter, Kg-m, Convert to Kilogram Centimeters, Kg-cm, Convert to Gram centimeter, g-cm, Convert to ounce-inch, oz-in, Convert to foo.

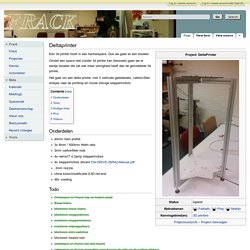

Stepper motor,Stepping gearmotor wholesale,Stepping motor supplier,Drives. Welcome to ReprapWorld.com. Delta Robot 3D Printer. Rat Rig Online Store. Mechanisch. Deltaprinter - Frack - Hackerspace Friesland. Een 3d printer hoort in een hackerspace.

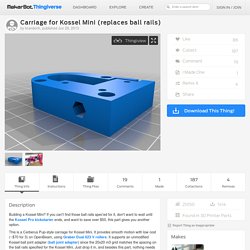

Dus we gaan er een bouwen Omdat een space niet zonder 3d printer kan (heuswel) gaan we er eentje bouwen die net wat meer stevigheid heeft dan de gemiddelde 3d printer. Het gaat om een delta printer, met 3 verticale geleiderails, carbon-fiber stokjes naar de printkop en mooie stevige steppermotors. Onderdelen. Jcrocholl (Johann C. Rocholl) Carriage for Kossel Mini (replaces ball rails) by brandonh. Required Parts (per carriage): 7x m3 nuts 3x m3 nyloc nuts - regular m3 will do too, in a pinch. 1x m3x16mm screw 5x m3x25mm screw 1x m3x40mm screw (for tensioner) 1x m3 washer 3x Graber Dual 623 V rollers I purchased all of the fasteners from MrMetric.com, and splurged on stainless socket head cap screws.

The list is fairly long, but aside from printing, getting these rolling won't take much time. Print at low-to-moderate infill. 30% with 3 perimeters is plenty rigid for me, but you could always go higher. I've done 0.4mm layers with a 0.5mm nozzle with good results. Deltabot Google group post with more info and pictures. OpenSCAD source and latest mods are available on the GitHub repo. Lineage: Steve Graber made the original design for Cerberus-Pup.

Helium Frog Delta Robot. This page is a development stub.

Please enhance this page by adding information, cad files, nice big images, and well structured data! Helium Frog Delta Robot Release status: unknown Introduction. Delta movement calculator. OpenSource 3D Printing - Deel 2 - Elektronica. Open Source 3D printing - Deel 2 Dit is het tweede deel van het topic, link naar het vorige deel.

Introductie Welkom in het open source 3D printing topic, de plek voor al je vragen, opmerkingen discussies en nieuwtjes op het gebied van 3D printen met open source printers. Onder open source printers verstaan we alle niet-closed source commerciele printers zoals alle RepRap printers, Ultimaker, Rostock ect. Minder bekend zijn we hier met Stratasys ect. The Helium Frog Delta Robot. Back to Helium Frog Blog CAD Models Details Other Robots20/10/2010This page is dedicated to the development of the Helium Frog Delta Robot.

The design is mostly complete and if you would like to help with the development please feel free. Some basic .stl models are available here to get you started. I will try to post the latest designs soon. Check the blog page for the latest progress. If you would like to see it working, check out the video on youtube by clicking the link below.

E3D-v6. V6 Video Check our our short and informative video introducing you to V6.

Print the Widest Range of Materials Possible. Building on our signature high temperature performance that allows you to print high temperature materials we've now focussed on adding increased functionality with soft and flexible filaments. Airtripper Bowden Extruder BSP Edition by Airtripper. Full documentation for the extruder is here: Extruder Filament Drive Gear Review & Benchmark Airtripper Direct Drive Bowden Extruder BSP Edition Designed for 1.75mm Filament and Nema 17 Stepper Motor This is the latest edition of the airtripper extruder series with many improvement tweaks and now is sporting a BSP fitting filament out feed socket.

3D Printing with Delta Printers. Rostock Delta 3D printer build. Rostock ! Hello and welcome to the Rostock build, it's take a while to get this one documented, I blame that on having way too much fun with my printers and development at the moment, I'll try to be a little quicker on future projects. The Rostock 3D printer was originally developed by Johann C. Rocholl and is now quite well established in RepRap terms, it's over a year old and has had many different spin-off's and variants by other users and developers.

Even Johann has a new design (Kossel Wiki here) based on the openbeam Aluminium construction.I rather liked the simplicity of the original design, and while I thought about making an aluminium T-slot design around the time SeeMeCNC were doing their very impressive development, I settled on just a few small changes for my Rostock build. The Rostock has a Delta configuration (Stewart platform) rather than the more common Cartesian coordinate system used by most other RepRap's. They should be tight and still rotate freely, but not spin. Rostock.