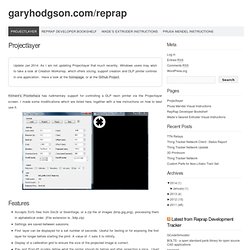

Getting Started! Reprap » Projectlayer. Projectlayer Update Jan 2014: As I am not updating Projectlayer that much recently, Windows users may wish to take a look at Creation Workshop, which offers slicing, support creation and DLP printer controls in one application.

Have a look at the homepage, or at the Github Project. Kliment’s Pronterface has rudimentary support for controlling a DLP resin printer via the Projectlayer screen. I made some modifications which are listed here, together with a few instructions on how to best use it. Features Accepts SVG files from Slic3r or Skeinforge, or a zip file of images (bmp,jpg,png), processing them in alphabetical order. Downloads Additional Python Dependencies pycairo Controls Overview A help option is available in the dialog to say what each control does.

Buttons Load: Opens a file dialog to choose an SVG file created from Slic3r or Skeinforge, or a zip file of bitmap images (with extension: .3dlp.zip).Present: Starts the presentation of the slices.Pause: Pauses the presentation. Settings. mUVe 1 3D Printer. The mUVe 1 3D printer is bridging the gap between the hobbyist maker and the high-price resin printers that are currently out of their reach.

The mUVe 1 uses a standard 405nm UV laser diode and a 3 axis CNC system to bring all of your high-resolution 3D models to life. When we set out to design a 3D printer we needed it to be as open and upgradable as possible, but it still had to offer great features at a great price. The mUVe 1 is completely open, we share everything, the designs, the software, all of it! On top of it all we still manage to do it for less money than anyone else, and it’s extremely energy efficient with only 25 watts of power consumption on average. Please read on below to see why the mUVe 1 should be your next 3D printer. 2 NEW KITS! -Aluminum Case Complete Kits available for those who want to get printing right away and want a sleek and durable case to house their machine. 3d Printer DLP. Software is responsible for the all of the calculations and controls of a 3D printer.

A STL file is an input for the software. This 3D model must be sliced into 2D images according to the given layer height. These images will be projected on a photo sensitive resin in order to cure it. The software is also responsible for controlling the motors for the motion. It is better to divide these tasks, so that each task can be done with different software. Software. 3dlp-host-software - A Complete STL slicing, host software, and firmware solution for DIY DLP-based 3D Printing. 3D Printing. Well, it's been a while - I haven't updated the 3DLP Host Software since I came out with the first Alpha version back in May.

This past weekend I started working on a complete revamp of the software - and when I say revamp, I mean that by the time I'm done, nearly every line will be replaced with better, more robust code. Planned features for the next release of the software include: 3D STL importer/viewer, 3D realtime slicer, re-written Arduino firmware, a new, cleaner GUI, slice previewing, and a manual printer control dialog. I'm also working on an efficient automatic support generation algorithm that I plan on implementing in later releases. P13552 / Home. Team Members Current Project Summary One of the goals this team had upon starting this project was to not restrict themselves based on what the previous teams had done.

They started by exploring a variety of new and different ideas including a different curing set-up, a different shearing device and a different photopolymer. The biggest problem faced by last year’s team was that when the projector cures through an optical medium onto the build platform, the resin sticks to both the optical medium and the build platform.

3D Printing Made Easy. MiiCraft - A pico projector based home built DLP 3D printer. The Peachy Printer - The First $100 3D Printer & Scanner! by Rinnovated Design. Below is a detailed video explaining how the Peachy Printer works through explanation and demonstration!

The peachy printer is a Photolithographic printer. That means it uses a controlled beam of light to cure light sensitive resin into hard objects. The peachy moves a laser beam along the X and Y axes to create the shape of the object, while using a drip system to control the level of the resin on the Z axis which determines the height of the object. 3DPrint - DIY: Autres projets / Electronique / Divers. 3D Printer. Construction d'une imprimante 3D - Le blog de richard 68.

Mercredi le 14 Décembre 2011 Réaliser des petits objets en 3D c'est possible, pour ce faire il nous faut un vidéoprojecteur, une plateforme élévatrice et une résine que l'on polymérise aux rayons UV.

La première chose à réaliser c'est la plateforme élévatrice. Le socle est une grosse plaque d'aluminium de 2 cm d'épaisseur, la stabilité doit être excellente. Le miroir optique incliné à 45º n'est pas encore fixé sur son support, mais il le sera prochainement. Voici une vue sous un autre angle, tout le châssis est fait en médium de 10 mm, la cuvette est en plexiglas . Sur cette photo on peut voir le micro manipulateur, en tournant la molette graduée au 1/10 mm le plateau de la cuvette peut descendre de 20 mm.

Dimanche 15 Janvier 2012 La petite plate-forme élévatrice a été confectionnée pour des tests rapides de polymérisation de la résine. Le micromanipulateur n'autorise seulement que des déplacements de plateau de 20 mm. Lundi 16 Janvier 2012 Voici la pièce qui rattrape le jeu. ChemShapes.