Joint Israeli-US fund invests $4.8 million in clean energy. Technology.

(Illustrative). (photo credit: INGIMAGE) A public fund – supported by the Energy Ministry, the US Depart- ment of Energy, and the Israel Innovation Authority – announced on Sunday that it would finance five joint clean energy projects to the tune of $4.8 million. Landfill gas generator. 7kW Biomass Electric Generator.

Electricity Generation - Ministry of National Infrastructures, Energy and Water Resources. Israel. In August 2015, we acquired 100% of the shares of OPC-Hadera from Hadera Paper, a large paper and paper product manufacturer in Israel.

The consideration for the transaction was NIS 60 million(approximately US$16 million). Inhabitat - Green Design, Innovation, Architecture, Green Building. BioMax® — SynTech Bioenergy. SynTech Bioenergy. Cogeneration. Cogeneration or combined heat and power (CHP) is the use of a heat engine[1] or power station to generate electricity and useful heat at the same time.

Trigeneration or combined cooling, heat and power (CCHP) refers to the simultaneous generation of electricity and useful heating and cooling from the combustion of a fuel or a solar heat collector. Cogeneration is more thermally efficient use of fuel than electricity generation alone. In separate production of electricity some energy must be rejected as waste heat, but in cogeneration this thermal energy is put to good use. Combined heat and power (CHP) plants recover otherwise wasted thermal energy for heating.

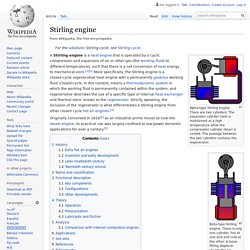

This is also called combined heat and power district heating (CHPDH). The supply of high-temperature heat first drives a gas or steam turbine-powered generator. Cogeneration was practiced in some of the earliest installations of electrical generation. Overview[edit] A cogeneration plant in Metz, France. Types of plants[edit] Stirling engine. Alpha-type Stirling engine.

There are two cylinders. The expansion cylinder (red) is maintained at a high temperature while the compression cylinder (blue) is cooled. The passage between the two cylinders contains the regenerator. Beta-type Stirling engine. There is only one cylinder, hot at one end and cold at the other. Home JENZ GmbH, Technology to process biomass, Mobile Chippers, Stationary Chippers, Chipper trucks, Biomass processors, special machines. Our conceptSustainability means to increase the energy and resources productivity by the efficient use of raw materials and to produce innovative and high-quality machines for the recycling of biomass in an environmentally friendly way.

Kogenerzia pdf. Towards energy self-sufficiency at a wastewater treatment plant - Cogeneration & On-Site Power Production. Wastewater treatment plants are a classic application for CHP, as the fuel, power and heat loads are all present.

Here, Ed Ritchie reports from one plant which has also added solar PV, on-site wind and hydro power to reach the point where it supplies all its energy requirements. The Gresham Waste-water Treatment Plant in Oregon, US, missed an important anniversary in January 2011. That was when the utility had expected its six-year old CHP system to have paid back its cost and to start turning a profit. There was no celebration, but no disappointment either, because the system actually hit that break-even date about 19 months earlier, in May of 2009. But this is more than a financial success story. Wood waste gasification plant to generate 10 MW in UK « Recycling « Waste Management World. Birmingham Bio-Power has awarded a £47.8 million contract for the design, build and maintenance of a new 10.3 MW biomass gasification facility in Tyseley, Birmingham.

Site preparation work will begin immediately with completion scheduled for early 2016. The plant will be supplied with approximately 67,000 tonnes of class A-C recovered wood waste secured under a long-term sustainable contract with a local supplier. Over its 20 year lifespan, the facility is expected to reduce greenhouse emissions by an estimated 2.1 million tonnes and save 1.3 million tonnes of waste wood, otherwise destined for landfill.

Gasification Plant Turns Wood Waste to Energy. Falcon Waste Development Land Company, part of the Larkfleet Group, and React Energy have submitted a planning application to build an energy recovery facility in Clay Cross, Derbyshire, UK.

The two companies are partners in Clay Cross Biomass Limited. The company has been established specifically to develop the Clay Cross Energy Recovery Facility, which will produce heat and electrical power by gasification of waste wood from construction and demolition, commercial and industrial sources. When running at full capacity the plant will be able to generate around 12MW of electrical power. Some of this will be required for operating the facility but about 10MW will be exported to the electric grid network. In addition to electricity, the plant will produce up to 10MW of thermal energy in the form of hot water or steam. CEN TC 343 - ERFO. The work of CEN TC 343 is based on the work done on a mandate of the European Commission.

The mandate is on producing all necessary standards on solid recovered fuels (SRF). 407430. Besides Pelletizing Equipment, What Factors Affect Pellet Strength. Besides pelletizing equipment, there are factors influence your pellet strength and durability.

In order to improve your pellet quality and the working efficiency of your pelletizing equipment, it’s better to learn about the factors, such as moisture content, particle size, preheating condition, chemical composition of raw materials, binders, and/ or lubricants, and other processing factors concerning the pelletizing equipment. Moisture Content Moisture content is always one of the most influencing factors on pellets strength and durability. The right amount of moisture functions as a agent during the process of pelletization which will influence the pellet strength and durability by spreading the lignin which will form a natural “glue” that holds the pellet together as it cools down.

Winwerksipd. Cogeneration is integral to the operation of modern facilities such as the UC San Diego campus, where a 30-megawatt system is used to provide 85% of annual electricity consumption. UC San Diego’s system received an EPA Energy Star CHP award as a result of its positive impacts to the environment by drastically lowering emissions and greatly improving energy savings. According to statements provided by UC San Diego, implementing cogeneration has resulted in $8 million per year worth of energy savings, and has also bolstered the self-reliance of the campus and decreased its vulnerability to power outages and congestion of the electrical grid.

UC San Diego’s system has a net operating efficiency of 66%, and requires 26% less fuel than a typical system involving purchased electricity and onsite thermal generation. The financial returns from UCSD’s cogeneration plant are astounding, and are compounded by decreased carbon emissions. טלמניע - Telemenia - A Global Power Provider. חב' ''טלמניע'' תקים עבור קבוצת רימון 2 תחנות כוח בישראל בטכנולוגיית קוגנרציה בהספק של 5 מגה ואט ובהספק שך 2.5 מגה ואט.

קוגנרציה - משרד התשתיות הלאומיות, האנרגיה והמים. Redivivus Homepage. WB 0216 Digimag by Café Racer Magazine - issuu. Towards energy self-sufficiency at a wastewater treatment plant.