Injection molding meets 3D printing in this 300 piece 3D printed injection molding machine. Mar 31, 2016 | By Kira Additive manufacturing or Injection Molding?

It’s a debate that has been going on for years, particularly since 3D printing became known as Fourth Industrial Revolution, promising to displace the cost, time, and material waste associated with traditional scale-production techniques. What has become apparent over the years, however, is that 3D printing and injection molding don’t necessarily have to compete—they can co-exist, and even complement one another. Whereas 3D printing is best used for rapid prototyping or last-minute, low-volume production, injection molding is the industry standard for high-volume manufacturing at unmatched speeds.

Each has their strengths and weaknesses, which are sure to be improved on as technology advances, however at the moment, it seems that there is room even with a single business for both, whether they are used to create common household goods or aerospace-ready parts. Posted in 3D Printing Application Maybe you also like: inShare78. Soda Locker Vending Machine Made with 3D Printed Parts. High school student builds a soda locker vending machine from Arduino and 3D printed parts.

And bags himself a prom date in the process. With books losing ground to tablets and computers, the humble school locker sure ain’t what it used to be. So why not retrofit the space to house a personal vending machine? High school student and maker Blake Hawkins has done exactly that. This custom setup can sell two types of soda to students in need of a caffienne buzz. As Hawkins explains on his Instructables project page: “A little less than a year ago, on the way back from lunch to U.S History class, I looked at one of the lockers and thought ‘how cool would it be to have a vending machine fit entirely inside of a locker?’ See the soda locker vending machine in action in the video below: Soda Locker Vending Machine is a Hit With the Kids The cylindrical device was modelled in Autodesk 360 Fusion and fabricated for Hawkins by MakeXYZ, a third-party 3D printing service. Could not resolve host: urls.api.twitter.com Stuck for ideas for what to 3D print?

Bored of pointless 3D printer projects? Here is a list of cool things to 3D print which are genuinely useful. Don’t miss: 34 Best Sites for Free STL Files and 3D Printer Files/Models Like us, you’re tremendously excited by the possibilities of 3D printing. Fight the tide of mediocrity! Don’t have access to a 3D printer? Cool Things to 3D Print #1: Sliding Door Bolt Obviously, this sliding door bolt will not protect you against breaking and entering. Cool Things to 3D Print #2: Monster Mouth Headphone Holder If you like to use a large pair of headphones at your desk, then this “monster mouth” could be just what you need. Cool Things to 3D Print #3: Out of Office Desk Sign Rushing off to a meeting?

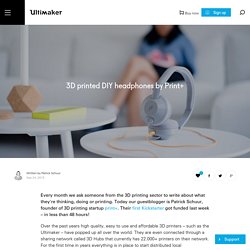

40 Cool Things to 3D Print Which Are Actually Useful. 3D printed DIY headphones by Print+ Every month we ask someone from the 3D printing sector to write about what they're thinking, doing or printing.

Today our guestblogger is Patrick Schuur, founder of 3D printing startup print+. Their first Kickstarter got funded last week – in less than 48 hours! Over the past years high quality, easy to use and affordable 3D printers – such as the Ultimaker – have popped up all over the world. They are even connected through a sharing network called 3D Hubs that currently has 22.000+ printers on their network. For the first time in years everything is in place to start distributed local manufacturing of consumer goods.

The first product print+ has developed is a DIY headphone kit. The concept is easy: print+ sends people a kit with all the essential electronics and non-printable parts, all people have to do is print the parts and assemble the product. All people have to do is print the parts and assemble the product. The headphone is only the beginning for print+.