Why Use Lime Instead Of Cement. Insulated Earthbag Foundations. Note: If you’re new to earthbag building, first read the introductory Step-by-Step Earthbag Building and How to Build an Earthbag Roundhouse .

This Instructable includes complete step-by-step instructions on how to make an insulated earthbag foundation. You can use the same process to make insulated foundations for any type of structure – straw bale, earthbag, cordwood, etc. Yurts or gers are very efficient and practical in harsh, cold climates, as evidenced by centuries of use in Mongolia. Benefits of yurts include affordability, rapid construction, ease of construction, wind resistance, great looks and portability (ability to take your home with you if you ever move). You may even save on taxes since some jurisdictions do not consider yurts permanent homes. Native American House Construction & Wigwams. Jordi Canosa: Strawbale, Cob, Or Earth Beauty.

Cordwood Building. Loghomeology - Building & Care Of Log Homes. Sourcing Round Wood Timbers From the Forest. It’s been several months since I’ve written.

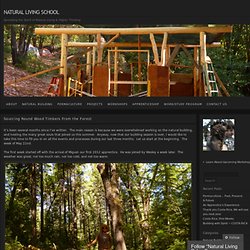

The main reason is because we were overwhelmed working on the natural building, and hosting the many great souls that joined us this summer. Anyway, now that our building season is over, I would like to take this time to fill you in on all the events and processes during our last three months. Let us start at the beginning. The week of May 22nd. The first week started off with the arrival of Miguel, our first 2012 apprentice. Miguel after debarking one large cedar tree The main task during our first weeks was to source the lumber for the timber framing, so the timbers would have 60 days to dry before we put them up. Debarking Cedars, Oaks, & Madrones.

After we cut the timbers, the next task was to debark them.

We had a small window to accomplish this. Most conifers have lots of moisture under their bark at the end of spring. After the last rain, your clock starts ticking. In most parts of the northwest, you will be able to debark relatively easy until mid June and if your lucky mid July at the latest. Debarking a Cedar after spring rains is fast and easy. Building Or Making. July 03, 2013 06:59 AM Category: Building or Making Take a look at a simple way to turn timber into lumber ... in episode 5 of The Farm Hand’s Companions Show right here, or read the post that follows belowThere are two basic ways that lumber can be made: sawing or splitting.

But successful lumber splitting requires long, straight-grained timber with a minimum of knots that tend to interrupt the split. This was easier done in the last century with the abundance of so much old growth pine that had populated the woods of the area where I live. It could still be done today with the relatively more knotty timber; but hatchet, broadaxe, or adze trimming would take more of my time and labor. I may yet attempt it in future outbuildings (maybe something not so large), but for the new pole-barn style workshop I’ve recently begun, I've chosen to saw the lumber. I felled the trees back in February before the sap started rising. How To Split Lengths Of Untreated Round Wood. There’s always a sense of adventure when ordering untreated, un-processed fresh from the wood timber.

I needed some untreated chestnut fencing posts (chestnut doesn’t rot easily so lasts longer in the ground than any other UK wood apart from oak) and after several weeks of trying to track down a local supply (it felt like I was trying to buy something illicit) I found some being sold from a wood about three miles away. Absolutely perfect! Totally local! Practically zero carbon emissions. Just what I wanted. You’ll need three or four heavy metal wedges – at least one of which should be smaller than the others. Some wood splits more easily than other wood.

To split the wood in half you need to find the centre of the rings at the end of the wood. Once you have hit it in far enough you will notice that the wood starts to crack in the centre of the ring and also on the top of the wood. Bash this in and the split will continue beyond the wedge and along the wood.

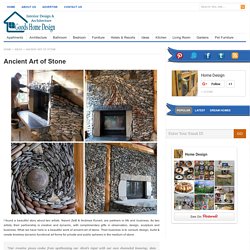

Straw-Bale Building. A Tiny House Built From Slip-Straw In Asheville, USA. Building With Hyper-wattle. Ancient Art Of Stone. I found a beautiful story about two artists.

Naomi Zettl & Andreas Kunert, are partners in life and business. As two artists, their partnership is creative and dynamic, with complimentary gifts in observation, design, sculpture and business. What we have here is a beautiful work of ancient art of stone. Their business is to consult, design, build & create timeless dynamic functional art forms for private and public spheres in the medium of stone. How To Build A Stone Foundation. When I decided to build a forest cabin back in 2009, I knew almost nothing about building. Over the next three years I learned a lot about construction, including how to create attractive, long lasting stone foundations for almost no money.

If you’re putting up a building and think you’d like to set it on something more beautiful than cinderblocks or Sonotubes, this blog might just provide the inspiration you need. Choose and Prepare a Location. Hypertufa Pots (Perlite, Peat Moss, Cement) .I’m so excited to be here at Remodelaholic guest posting again!

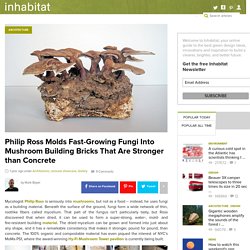

Thank you Cassity for having me! Please come and visit me at my blog, 33 Shades of Green. You’ll find me cooking, crafting, decorating, and trying out all sorts of creative projects. BioMason. Mushroom Bricks Stronger than Concrete. Mycologist Philip Ross is seriously into mushrooms, but not as a food -- instead, he uses fungi as a building material.

Beneath the surface of the ground, fungi form a wide network of thin, rootlike fibers called mycelium. That part of the fungus isn't particularly tasty, but Ross discovered that when dried, it can be used to form a super-strong, water-, mold- and fire-resistant building material.