Homemade Gears. Everything in the following webpage sections is what I have developed/learned through trial and error processes.

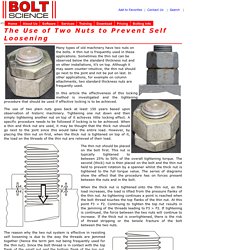

I'm sure that there are probably more correct ways to do this, but these may require expensive metal machining equipment. The following is what I have developed with my homemade equipment and lots of trial and error. Safety The remainder of this webpage describes processes that involved cutting and shaping metal. Eye protection was mandatory during all processes described on this webpage. Cutting The Gear Blank The gear blank requires cutting to a circumference that will contain an integral number of gear teeth. Indexing The Blank Before hobbing, the gear blank requires indexing. The threaded rod could grip into the masking tape and turn the unindexed gear blank. Gear Hobbing Below are three photos showing the hobbing process using a M12 tap (left and middle) and a M12 rod containing slits cut with a metal file (right). The Use of Two Nuts to Prevent Self Loosening of Fasteners. Many types of old machinery have two nuts on the bolts.

A thin nut is frequently used in these applications. Sometimes the thin nut can be observed below the standard thickness nut and on other installations, it’s on top. Although it may seem counter-intuitive, the thin nut should go next to the joint and not be put on last. In other applications, for example on column attachments, two standard thickness nuts are frequently used.

In this article the effectiveness of this locking method is investigated and the tightening procedure that should be used if effective locking is to be achieved. The use of two plain nuts goes back at least 150 years based upon observation of historic machinery. Homemade small dust collector: The blower. Shop vacs make convenient mobile dust collectors, but they are very loud and consume so much power that you often have to run them on a separate circuit.

Most shop vacs actually consume more power, and are louder than larger dust collection units like the one in the background of this photo. BuildYourIdea.com. Marble adding machine. Illustrating How Mechanical Assemblies Work. Qi - How to Make (Almost) Anything. Shape memory alloys (SMAs) are metals that change shape when heated up.

They are wonderful actuators in that they are light, silent and can be "turned on" by simply running current through. The shape that they change to can also be set, though this process is a bit more tricky. Flexinol is a particular brand of nitinol, which is an SMA made of nickel and titanium, and is pre-set to contract about 10% of its original length when heated. The Flexinol that I used is from robotshop.com, which provides a useful chart of different wire properties here. The general trends are: All wires take about 1 second to heat up and contractHigher diameter wires have more pulling force than lower diameter wiresHigher diameter wires have longer off times (it takes longer for the wire to return to its original, un-contracted shape)Higher-diameter wires have lower resistance and draw more power.

In order from top to bottom, the clips on the left are: How crowned pulleys keep a flat belt tracking. Before V-belts were invented, machinery was usually powered through flat canvas belts running on crowned pulleys.

These flat belts stayed centered on pulleys without any guides or flanges. The key to keeping them tracking centered on the pulleys is the use of "crowned pulleys". A crowned pulley is a pulley that has a slight hump in the middle, tapering off ever so slightly towards either edge. How a crowned pulley keeps the belt tracking on it is a mystery to most people, so I thought I'd write a small article explaining how it actually works. The key to understanding flat belt tracking on a crowned pulley is to look at how a belt flexes when pulled more on one edge than another. I'm pulling the rubber band in the photo on just the right edge. To better demonstrate the principle, I built a jig from lego, using a rubber band and an exaggerated crowned wooden pulley.

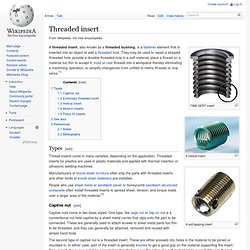

Poser une fenêtre aluminium en vidéo - Castorama. Woodworking machinery. Threaded insert. TIME-SERT insert A helical insert A self-tapping insert Types[edit] Thread inserts come in many varieties, depending on the application.

Threaded inserts for plastics are used in plastic materials and applied with thermal insertion or ultrasonic welding machines. Manufacturers of knock-down furniture often ship the parts with threaded inserts and other kinds of knock-down fasteners pre-installed. People who use sheet metal or sandwich panel or honeycomb sandwich-structured composite often install threaded inserts to spread shear, tension, and torque loads over a larger area of the material.[2] Captive nut[edit] Captive nuts come in two basic styles. The second type of captive nut is a threaded insert. Threaded inserts are commonly used in plastic casings, housing, and parts to create a metal thread (typically: Brass or Stainless Steel) to allow for screws to be used in the assembly of many consumer electronics and consumer products. Externally threaded insert[edit] Helical insert[edit] How It's Made: Optical Lenses. Extruder to Recycle Plastic Milk Bottles.

RCV - How it Works. Wood Shop tricks.