METO Systems

METO Systems provides assistance with equipment installation, machinery start up, and operator training. We provide ongoing and preventative maintenance support.

METO SYSTEMS AT PACK EXPO Las Vegas – September 25 – 27, 2017. Drum Handling Equipment a Wise Investment for Safety and Efficiency - METO Systems. Large, heavy drums can be cumbersome and even hazardous to maneuver.

Having the proper drum handling equipment can mean fewer accidents and a safer work environment for your employees. In this article we will discuss METO Systems’ drum handling equipment along with some of their benefits. ISPE DVC 2020 Exhibitor Page Now Live! - METO Systems. Best in Class Pharmaceutical and Nutraceutical Handling Equipment - METO Systems. The OSD Pharmaceutical, the Nutraceutical, and Fine Chemicals & API industries all have one thing in common: the need to protect the purity of the materials being handled and processed.

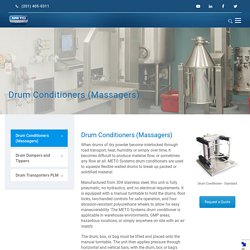

METO Systems recognizes that equipment provided to these industries must be constructed to a consistent standard to minimize the risks involved in production. We have built a long and trusted reputation for equipment compliance, providing DQ, IQ, OQ and PQ documentation required for process validation. We produce products that can handle everything from fine powders and particulates, such as those produced during milling, to granulated compounds and large collections of pressed tablets. These industries have the most precise requirements and manufacturing guidelines in terms of quality. As a result, it is critical that pharmaceutical and nutraceutical manufacturing equipment comply with good manufacturing practice (GMP). All of our equipment continues to be designed for a lifetime of reliable service. Drum Mower With Conditioner. When drums of dry powder become interlocked through road transport, heat, humidity or simply over time, it becomes difficult to produce material flow, or sometimes any flow at all.

Powered mobile and permanently mounted equipment - METO Systems. METO Systems Specializes in Powered Mobile and Permanently Mounted Equipment for use in All Regulated Manufacturing Industries.

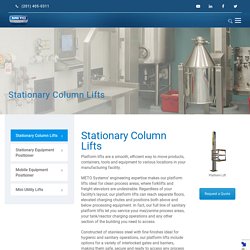

For more than 50 years, METO Systems has been a leading supplier of process and material handling equipment for a variety of highly regulated industries, including all aspects of the consumer health industries, fine chemicals, power generation (battery), and food. Material handling equipment provided to these industries must be constructed to a consistently high standard of GMP, to minimize the risks involved with production demands We have built a long and trusted reputation for equipment compliance, providing DQ, IQ, OQ and PQ documentation, FAT and SAT testing requirements and a full complement of after-sales support including start-up and operator training. We understand the needs of a qualified facility operating under strict manufacturing guideline and regulations. In conclusion, our equipment continues to be designed for a lifetime of reliable service. Drum Handling Equipment. Blender Machine Online. Stationary Column Lifts. Platform lifts are a smooth, efficient way to move products, containers, tools and equipment to various locations in your manufacturing facility.

METO Systems’ engineering expertise makes our platform lifts ideal for clean process areas, where forklifts and freight elevators are undesirable. Regardless of your facility’s layout, our platform lifts can reach separate floors, elevated charging chutes and positions both above and below processing equipment. In fact, our full line of sanitary platform lifts let you service your mezzanine process areas, your tank/reactor charging operations and any other section of the building you need to access.

Stationary Equipment Positioner. METO Systems offers a variety of options for our equipment positioners.

Choose between pneumatic, electric drives and pneumatic, electric, basic, semi-automatic and full PLC automation controls. You can also add an integrated system that allows for communication with plant control systems. Another option includes manual or powered swivel rotations of the lift column to help ease positioning of the elevated load. These versatile columns can rotate through a 360-degree arc and are capable of supporting multiple destinations—all without sacrificing precision. We can customize our equipment positioners to accommodate integrated weighing operations and XP rated areas, and configure lift attachments to the requirements of your specific application.

If moving equipment to a precise location is a frequent need for your production or manufacturing operation, METO Systems equipment positioners can make your life a whole lot easier. Powered Mobile Straddle Stacker PMSS. Tight spaces are no match for METO Systems’ straddle stackers.

With adjustable spread outrigger legs, this stacker is perfect for working in process suites, airlocks and other small spaces. This versatile, powerful and compact stacker has a short turning radius, making it the ideal choice for narrow aisles, process suites, airlocks, or where space is at a premium. Ideal for special lift requirements inside clean process areas. Can easily lift and move up to 3000 lbs/1361 kg. Part of METO Systems’ Powered Mobile Series, the straddle stacker is fabricated from 304L stainless-steel and designed for use in cleanroom applications. The auto-reverse belly switch and up/down buttons with proportional speed control make these stackers simple to operate.

If you’re looking for the operational efficiency only a straddle stacker can provide, consider a METO Systems unit that will reward you with increased productivity and lower costs. Powered Mobile Pallet Jack PMMJ. The efficiency and ease-of-use of the METO Systems’ powered pallet truck makes it the ideal solution for transporting bins throughout your sanitary manufacturing process.

This versatile, powerful and compact stacker has a short turning radius, making it the ideal choice for narrow aisles, process suites, air locks, or where space is at a premium. Part of METO Systems’ Powered Mobile Series, the powered pallet truck is fabricated from 304L stainless steel and is designed for use in clean room applications. Ideal for special lift requirements inside clean process areas. Can easily lift and move up to 3000 lbs/1361 kg. Container Transports. Transporting large product containers through your facility is not always simple.

Many bins or bowls are fitted with their own wheels or carts while others require a separate mode of transportation. Large sacks, for instance, are typically moved around on pallets or in suspension frames and therefore have very unique transport requirements. METO Systems offers a number of options for bin transports, ranging from simple stainless steel pallet jacks to powered pallet jacks and counterbalanced stackers. We even offer powered utility tugs that can move heavy carts and work with your existing mobile equipment. Our lift trucks are EE-rated and include an electric code switch that allows for up to 99 individual access codes, as well as a “last-user ID” function to make startup easy.

Buy Bulk Bags Column Lifts. METO Systems’ stainless-steel container positioners are designed to be safe, easy-to-use and reliable.

They are Industry standard for the transfer of powders/pellets/tablets from either an IBC, FIBC or similar. Many process applications call for lifting containers and then positioning them over a receiving port, stacking position, or a wash nozzle; or for placing them onto a special discharge station. Meto Bin Positioners are capable of reliable and consistent precision docking. METO Systems offers a variety of positioner types—from small column lifts to fully integrated lifts—to meet your specific needs.

What To Look For In A Powered Mobile equipment. Looking for a piece of machinery that can move bins with ease, in the most safe and constructive manner possible? Look no further than our selection of METO powered mobile equipment, which include our powered pallet jack, powered mobile straddle stacker, and powered mobile counterbalanced stacker. When it comes to equipment, you want machinery that is durable, yet easy to operate and maneuver about the factory. The METO powered pallet truck is fabricated from 304L stainless steel and is designed for use in clean room applications, thanks to its short turning radius.

Ideal for special lift requirements inside clean process areas, it can easily move up to 3.000 lbs/1.361g. Container Blending. Choosing The Best Lifting Equipment: 5 Pieces of Advice You Should Follow - METO Systems. Choosing the right lifting equipment for your business may be puzzling at first, as there are many providers and pieces to choose from. If you are scratching your head, wondering where to begin, allow us to provide you with some pertinent insight. Before making a purchase of any kind, you should list your expectations for use and capability, as well as any issues you need solved. Let’s say that simply lifting and dumping has proven to be an insufficient production-approach for your company. You may need a method of accurately positioning your product as it flows from the drum.

Find Us At Pharmaceutical Technology! - METO Systems. COVID-19 - METO Systems Declared Essential - METO Systems. Dear Friends and Colleagues, COVID-19 is exerting enormous pressure on our way of life, especially on our care givers, hospital workers and first respondents. We at METO Systems want to sincerely, thank and acknowledge our domestic and international pharmaceutical clients. Their employees are working under great pressure to not only continue their vital operations, but to help innovate solutions and fight this global pandemic. METO Systems has a history of supporting this vital part of our economy with essential equipment, on site services and spare parts. We are committed to remaining in business during these difficult times and equally committed to facing the many challenges of today. Our facility at Franklin Lakes NJ has received an exclusion from the shut down due to our role in the pharmaceutical supply chain.

Our manufacturing facility will remain fully manned. This means we are open for business as usual. Stationary Column lifts. Stationary Equipment Positioner. Telescoping Mobile Drum Inverter. Drum Transporters PLM. Mini Utility Lifts. Affordable Drum Tilter. Drum Inverters. Column Bowl Lifts. Most stainless steel bowl inverters—including those used with mixers, granulators or fluid bed dryers—do not provide a bottom discharge outlet. This means fine powders, wet powders, liquids and anything else that’s been mixed will require scooping, dumping or inverting for product removal.

METO Systems inverters are available with discharge cones that can accommodate either manual or automated clamping. In fact, we offer a full line of bowl inverters and tippers to help keep your product flowing. Even in the event of a power outage, our fail-safe lift mechanisms will hold the platform in place without drift. Drum Dumpers and Tippers. Drum dumpers, tilters and tippers are used in a variety of ways during industrial production.

They are ideal for charging coaters; filling hoppers, reactors and other process vessels; dispensing applications; and discharging powders, granules, pellets and tablets. A patented tilt profile system, and tampered custom chutes allow for ease in charging tablet coaters with vertical charging ports; filling hoppers, reactors and general applications. Regardless of the unit you choose, METO Systems’ dumpers, tilters and tippers include stainless steel construction with an upgradable finish; non-marking, white polyolefin wheels; powered floor-locking devices; and mounted, push-button controls. Tippers are used to position the drum downward, so the product can be easily discharged through a bung in the head of the drum. Stainless steel tippers are typically used when drums contain liquid.

Tilters are used to position the drum at an angle to control the discharge of material (usually powders). FIBC Docking System. Drum Mower With Conditioner. Container Transports. Container Blending. Standard Laboratory Blender. METO Systems’ stainless-steel lab scale blender mimics the full-size blender but sized for up to 5 ft. containers. The unit has a fixed height and will blend round or square containers. The base is fitted with full locking swivel casters and floor leveling locks to allow safe blending. Powered Mobile Pallet Jack PMMJ. METO SYSTEMS AT INTERPHEX NY, April 2-4 2019 - METO Systems. METO SYSTEMS returns to Franklin Lakes, NJ - METO Systems. METO will be attending the ISPE-CaSA Meeting (Carolina-South Atlantic Chapter) - METO Systems. Considerations When Purchasing Material Handling Equipment - METO Systems. Over the course of five decades, we have satisfied clients from various industries, such as Pharmaceuticals, Food Industry, Nutraceutical, and Fine Chemicals, by providing them with state-of-the-art equipment necessary to most efficiently run their business.

Of course, no two companies are the same, but there are a few common questions that all clients should be asking themselves before they make a purchase with us. What should a material handling equipment be capable of? When it comes to Material Handling Equipment, you want something that is uniquely suited for your business and performs as safely and smoothly as possible. You want equipment that will get the job done, within the least amount of time possible. You don’t want complex machinery that requires much effort on your end because, let’s face it, you already have too many tasks to attend to. What factors should you consider when purchasing a material handling equipment? Nutraceutical - METO Systems. The manufacturing of nutraceutical products can fall between food and pharmaceutical requirements depending on the specific guidelines for the product being manufactured.

Fine Chemicals & API - METO Systems. Active pharmaceutical ingredients, dangerous or volatile compounds, high-purity exotic products all require specialized manufacturing facilities and partners who understand the challenges of working with these materials. METO Systems has the experience to recommend and manufacture products that are suitable for even the most specialized application. METO Systems recognizes the need to protect the purity of the materials being handled and processed. Industrial Material Handling Equipment.