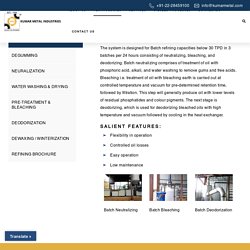

Fat Modification - Kumar Metal Industries. Oil Refining - Kumar Metal Industries. Deodorization Process This process is used to remove volatile matters and free fatty acids at high temperature and high vacuum to give stability and shelf life of edible refined oil.

Stripping:The hot oil enters the Packed Column, which is filled with special structured packing so that the oil is distributed into a thin film and is evenly agitated by stripping steam flowing counter currently from the bottom of the column. As a result, free fatty acids and other remaining volatile impurities in the oil are evaporated and removed with steam.

The residence time in the column is only a few minutes. The bulk of the free fatty acids along with aldehydes, ketones, etc. in the oil are quickly stripped off before any heat induced permanent damage has been done. Speciality Extraction - Kumar Metal Industries. The extraction plant has flexibility to process several different raw materials (Herbal plant material and spices) to produce aqueous and solvent extracts.

To retain flexibility and ensure quality most of the process equipment will be having stainless steel contact parts. Raw materials such as Tulsi, Ginger grass, lemon grass, cardamom, cinnamon Ginger, Turmeric, Chilli, Annato seed, Black pepper, nut-mug, etc can be processed. Preparation : To remove foreign impurities and to disintegrate into suitable size to facilitate extraction of active ingredients. Extraction : Aqueous extraction : By steam/water distillation for extracting essential oil water soluble extract separation of product and water.Solvent extraction : By using various type of solvents depending on raw material to be processed for extracting active ingredients.Solvent recovery : Extracted meal (spent raw material, extraction) and miscella containing active ingredient.

Solvent Extraction - Kumar Metal Industries. Process The solvent extraction process involves extracting maximum oil from prepared raw material.

This is accomplished by spraying hexane in different concentration on the moving extractor bed in a counter current manner. The Desolventiser Toaster ensures removal of hexane and minimises urease activity in the de-oiled cake with the help of controlled toasting. The consumed hexane is recovered in the distillation section which then gets recirculated back in plant. The extracted oil is pumped to storage tanks for further processing. Mechanical Extraction - Kumar Metal Industries.

Oil from Screw Press comes to Vibro Separator, where the core particles are separated by vibration.

Then the oil is pumped for final where plate type filters are used to remove the fine particles. The Vibro Separator is a separating machine which includes a vertical type special motor to facilitate three dimensional motions; composed, circular and elliptic in horizontal, vertical & inclinational faces. This Vibro Separator achieves superb performance as the feed (Crude Oil) is dispersed from the centre equally; hence all parts of screen cloth are fully utilized. Salient Features: Low maintenance costReduced down timeLonger screen lifeHigher separation efficiencyDust free noiseless processing Filter Press. Oilseed Preparation - Kumar Metal Industries. Seeds are thoroughly cleaned in a seed cleaner to filter impurities like dust, leaves, stems, etc.

They are then passed through a de-stoner to remove stones and sand. This removal of unwanted material reduces the down time and increases the life of machines. Cleaning is done in the multi deck seed cleaner. The Cleaner is composed of various sizes screen designed to segregate the different fractions. The aspiration system along with cleaner is used to remove light particles and loose hulls. Made of steel with sieve boat of laminated wood. CSR - Kumar Metal Industries. Quality Policy - Kumar Metal Industries. Worldwide Installations - Kumar Metal Industries. Manufacturing Infrastructure - Kumar Metal Industries. Kumar’s manufacturing and fabrication units span across 22,762 sq. meters, house over 400 skilled technicians, quality control personnel, dedicated workmen and the latest precision European machinery.

Our fabrication facilities are capable of manufacturing high pressure vessels and are equipped with certified x-ray qualified welders. For hard facing and critical wear and tear parts our highly trained TIG / MIG welders take over. Crucial to every part of the process, our quality department checks the project at every stage ensuring our clients always get superior quality products. Our equipment has a reputation of being robust in construction, superior in quality, versatile in nature and operationally profitable. Also, our vastly experienced personnel provide training to customers; operating staff. Crown - Kumar Advantage - Kumar Metal Industries.

Since 2003, Kumar Metal Industries is in Joint Venture and Technical Collaboration with world leaders in oil extraction and refining plants, Crown Iron Works Company USA and Europa Crown UK to manufacture Solvent extraction and edible oil refining plants incorporating Crown Technology.

Today’s agricultural industry presents a challenge. It has two very specific needs: high-capacity oilseed processing equipment and low operating costs. As a world-leading designer and manufacturer of oilseed processing equipment, Crown meets the needs of the agricultural industry and beyond—every day. As the largest supplier of oilseed preparation, extraction, refining, oleochemical/ biodiesel and specialty technology and equipment in North America, leading processing companies across the globe rely on the engineering capabilities of Crown Iron Works Company. Our Company - Kumar Metal Industries. Oil Refining - Kumar Metal Industries.

Deodorization Process This process is used to remove volatile matters and free fatty acids at high temperature and high vacuum to give stability and shelf life of edible refined oil.

Stripping:The hot oil enters the Packed Column, which is filled with special structured packing so that the oil is distributed into a thin film and is evenly agitated by stripping steam flowing counter currently from the bottom of the column. Mechanical Extraction - Kumar Metal Industries. Home - Kumar Metal Industries.