Blended Caulk, Paste, Putty, RF Absorber, Gap Fillers. Advanced Polymer & Caulk Systems Flight qualified system capable of accepting various filler types Internally developed system can be formulated to adjust pot life, time to cure/sand 2 part system provided in “SEM” type kits ARC Technologies will custom formulate alternative systems based on specific requirementsLearn More Spray Systems Custom blends Loading options available In house capability Limitless large and small size capacity On site installation available for large structuresLearn More.

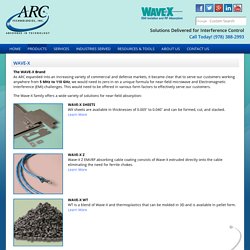

Electromagnetic Interference (EMI) Shielding. The WAVE-X Brand As ARC expanded into an increasing variety of commercial and defense markets, it became clear that to serve our customers working anywhere from 5 MHz to 110 GHz, we would need to zero in on a unique formula for near-field microwave and Electromagnetic Interference (EMI) challenges.

This would need to be offered in various form factors to effectively serve our customers. The Wave-X family offers a wide variety of solutions for near-field absorption: WAVE-X SHEETS WX sheets are available in thicknesses of 0.005″ to 0.040″ and can be formed, cut, and stacked.Learn More WAVE-X Z Wave-X Z EMI/RF absorbing cable coating consists of Wave-X extruded directly onto the cable eliminating the need for ferrite chokes.Learn More. Blended Caulk, Paste, Putty, RF Absorber, Gap Fillers. Portable Devices. At ARC Technologies we specialize in products to help assist RF and EMI problems in your portable device.

With our state of the art fillers we can target your problem and solve your customer specific needs; with multiple products on a wide range of MHz. Maximum Board PerformanceControl SAR Energy EmissionsNegate Chip Cross-TalkPass Compliance and Immunity TestStray Radiating Signal Control Applications:Surface Mount Small footprint on circuit boardPrevents cross talk between componentsQuiets noisy components Wireless WiFiInfrastructureHandsets/Tablets. Composite Machining, Extrusion Tooling, Thermoplastic & Foam Machining. CNC Machining, or computer numerical control machining, utilizes tools that can be computer controlled such as lathes, mills, routers and grinders.

At ARC Technologies, Inc. we offer the following types of CNC machining services. Honeycomb machining ARC Technologies, Inc. can machine a wide variety of honeycomb from something as simple as facing sheets to a desired thickness or complex pyramidal shapes. Our machining envelope for honeycomb is 60”x120” x 16” We can hold tolerances on Honeycomb in the cell direction to +/-.005” and with/across the ribbon direction + .030”/-.060” Electromagnetic Interference (EMI) Shielding. Automotive. The advances in the automotive industry today require components to have more power and energy than ever, and we can get your technology up to speed.

Automotive systems designers encounter unique problems with the development and deployment of high frequency radar systems in vehicles. Chief among these are: Cavity resonances within metal enclosuresCoupling between transmit and receive antennasReflections cause by adjacent metal structure on the vehicleFocus of the antenna pattern Resolution of these problems can be a complex task that may include circuit and antenna layout, enclosure design compromises, range and pattern concessions and placement within the vehicle. A sensible solution is the selection of high frequency radar absorbing materials suitable for the automotive environment. Material selection is critical to the resolution of radar resonance and interference issues. We offer the following products in the automotive industry: Focused Beam Testing (Permittivity & Permeability)

At ARC Technologies, Inc., we have the unique ability to customize.

Standard products may have electromagnetic interference issues caused by radio frequency that cannot be remedied with ordinary solutions.We have engineers with extensive experience in materials testing and characterization from an electromagnetic perspective. We are subject matter experts when it comes to testing permittivity and permeability. ARC’s experience with electromagnetic theory allows them to complete quality electrical testing in a timely manner. Electrical Characterization of Materials. Electromagnetic Interference (EMI) Shielding. ARC Technologies blends thermoplastics with fillers to create the solution to your problem.

ARC Technologies can manufacture thermoplastics to be used in a cast, molded, extruded, or pellet form. In the binder ARC Technologies can compound different fillers, typically: carbon, ferrite or iron particles to achieve the desired absorption or conductivity to solve the problem. By combining a binder that is in the form which meets the product requirements and with the fillers that also meet the electrical and magnetic properties, a complete solution can be met. Why Thermoplastics Are Effective The thermoplastic solution is very effective in solving the key issues of the problem. Parts can be molded to snap over the IC’s, or extruded to wrap and cover a product or cable, or sold as pellets so the end customer can mold/extrude their own product.

Electromagnetic Interference (EMI) Shielding. ARC offers the most sophisticated, light weight, high strength, structures in the Electromagnetic Interference (EMI) control industry.

Our knowledge, advanced manufacturing techniques, and commitment to added value result in unique solutions for a wide variety of applications. RF & Electromagnetic Interference (EMI) Shielding. At ARC Technologies, we have the ability to develop innovative solutions to address today’s interference problems in our Research and Development Labs as well as produce these solutions cost effectively on our manufacturing floor.

We have developed many different product form factors using our specialty fillers that absorb microwave and RF waves to allow your application to work properly. Product Overview Our latest product is the Hot Melt Absorber. Developed by our R&D team, this product gives the customer a very simple and fast way to apply absorber in their own facility, to a surface that requires noise suppression, for example a PCB. With any heat gun that reaches 300 degrees Fahrenheit, the customer can apply this product.

•HM1000 – Lightweight Dielectric Absorber HM1000 is ideal for applications that require a high frequency absorber above 10 GHz. Electromagnetic Interference (EMI) Shielding. Focused Beam Testing (Permittivity & Permeability) Lossy Foams & Multilayer Foam Absorber. LOSSY FLEXIBLE FOAM Ideal for suppression of electromagnetic energy Easily cut, wrapped and appliedLearn More MULTILAYER FOAM Broadband absorption from 500 MHZ to 40 GHz Controls surface currents Conductive ground plane available 70° to +270°F (-56.7° to +132.2°C)Learn More.

History. When Daniel P. Healey, Jr. established ARC Technologies in 1988, his vision was clear, focus on the customer’s needs and create a truly superior microwave absorber and composite materials company. Through Dan’s vision, ARC Technologies has dedicated itself to: UNDERSTANDING OUR CUSTOMER’S NEEDSDELIVERING QUALITY PRODUCTS ON-TIMEENGINEERING INNOVATIVE SOLUTIONS Today, ARC Technologies has over 200,000 square ft. of research, design, manufacturing, and office space in Amesbury, MA. ARC Technologies comprises of five focus factories that are responsible for each of ARC Technologies major product lines: MAGRAM/Dielectric MaterialsCompositesAdvanced MaterialsWave-XThermoplastic.

Composites, Elastomers And Thermoplastics Machining. Electromagnetic Interference (EMI) Shielding. Magnetic Microwave Absorber. DD SERIES Highly flexible; excellent environmental properties; UL94-V0 rated -60° to 375°F (-50° to 190°C)Learn More. Electromagnetic Interference (EMI) Shielding. Mechanical Testing. At Arc, our custom testing procedures, as well as product offerings, allow for one-stop-shopping. There’s no need to choose products and then send them away for testing; we can do both! This means reduced development time for customers that are having prototypes and development pieces built.

Electrical Testing. Electroless Plating and Conductive Products. Metal Plating As industry leaders, ARC Technologies Inc. is always striving to be on the forefront in EMI Shielding and Absorbing products. As part of those efforts, we are proud to offer ultra-high capacity Electroless Copper plating and our innovative AC2ES film plating lines. Download our Plating Capabilities Brochure here. Electroless Plating – Copper: Staying ahead of today’s technologies, ARC Technologies Inc. has installed an ultra-high capacity electroless copper plating line. Electromagnetic Interference (EMI) Shielding.