- 3D printing. (12) #258 Configurable Cases for your Projects (Arduino, ESP32, ESP8266) 5 best 3D printer filaments for outdoor use. One of the hallmarks of modern 3D printing is how these machines once known only for rapid prototyping, have become able to produce functional as well as ornate objects for simple everyday use.

But while the average PLA print from an FDM machine or a standard resin print from an SLA machine, would last an impressively long time inside the house, taking things outside into the open tends to be a little more complicated. In this article we will take a look at some of the best 3D printing materials available and the best filaments that have what it takes to withstand the harsh environment of the great outdoors. Best 3D printing materials for outdoor use This list is sorted with the most suitable material appearing first. However, ASA and PETG can be number one or number two interchangeably depending on the printer being used. #rcairplane. How to Build RC 3D Printed ASK14 Glider - Planeprint. Artilugios impresos en 3D. Jellybean3D. ADDING a 3-Wire Laser to a CR-10S 3D Printer : 18 Steps (with Pictures) - Instructables. The 5V PWM is the tricky bit.

Find this MOSFET in the pic above. Grab your multi-meter and test this pin CAREFULLY. On the CR10 screen, set your PART FAN to 0, 128, and 255. Your multimeter should show voltages of 0, 2.5V, and 5V respectively. NinjaFlex material is the leading flexible filament in the 3D printing industry. Flex filaments — HackSpace magazine. Printing flexible filament provides certain challenges.

The inherent stretchiness of the material makes them less suitable for Bowden tube extruders compared to direct drive. You can get them to work with Bowden machines, but particularly as you go down the Shore hardness scale, you’ll have to be very careful with your settings. Flex filaments are also very prone to stringing, and you may find that this is something that you just have to live with, and not something that you can solve with slicer settings. As the prints are flexible, any thin parts are prone to flexing as you try to print on top of them, so taller structures have to be stiff enough to stay still when printing. Keeping the speed slow can help with this, but you may find that certain designs that are printable with stiffer plastics just don’t work with flex.

Depending on the infill percentage and the hardness, flex filaments can be easy to bend, or fairly stiff Hardness is measured on the Shore hardness scale. How to Turn Your 3D Printer into a Plotter in One Hour. Teach Your 3D Printer How to Draw and Write on Paper with Pens, Color Pencils, Crayons and More!

🖍 Building a plotter was on my list for a long time. Making PCB with 3D Printer and permanent marker. There are a lot of ways to create your own PCB’s at home.

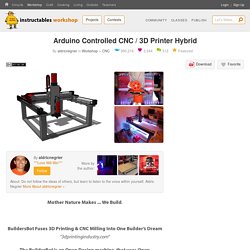

I have used the toner transfer method for a while, but it’s a pain to use the ironing iron and then dissolve the paper and so on. Some of the methods are: – Toner transfer and etching – Isolation routing with CNC – Draw with a permanent marker directly on to the copper clad and etch – UV light, photoresist PCB copper clad, transparency and etching. Arduino Controlled CNC / 3D Printer Hybrid : 20 Steps (with Pictures) - Instructables. Repetier or Marlin Firmware for Arduino Mega implement G2 an G3 circular interpolation so they are good to use for CNC and 3D Printing.

However they have limitations regarding pure CNC instructions such as pecking an other GCode's. Download and install Arduino IDE Here: Download and Repetier Firmware here: Configuring the Repetier Firmware for CNC functionality: After installing Arduino IDE, open it and use it to open the Repetier Firmware you have just download (repetier.ino file). - Arduino IDE Tools Tab: How to build a simple, cheap enclosure for your 3D printer - Prusa Printers. Maybe you have already seen some of those fancy enclosures people build for their printers.

How do they work? And do they work? Today, we will shed some light on this matter! Plus, we are going to dive into patent wars and explain why not all printers come with an enclosure. To top things off, we will even give you a full guide with information on how to build an enclosure for your own printer.

Stable printing environment – Drafts can negatively impact your print. However, if you’re not printing with ABS or other high-temperature filaments that suffer from warping, you won’t see much of a difference. How to use a parametric file – Serge Payen. Tutorial: how to use a parametric 3D model with the software OpenSCAD, in order to obtain a custom-made object.

Download OpenSCAD Introduction. How to Smooth Your PLA Prints to a Mirror Finish - Step-by-Step. Need to make your prints look super smooth?

Or perhaps you just want rid of those layer lines to make your print look more 'factory finished'? Make 3d Printed Topo Maps of Anywhere : 7 Steps (with Pictures) - Instructables. So hopefully by this point you have a downloaded and un-zipped GeoTIFF file.

Some of you may recognize that a TIFF file is a standard raster image file format. So it should come as no surprise that you can actually open this file with Photoshop or a similar program and look at it. It is a greyscale image where the darker areas represent lower elevations and the lighter areas represent higher points. The OpenRC F1 Build Guide - Daniel Norée. This is the build guide for the OpenR/C Formula 1 car. It´s the third generation 3D printed OpenR/C car and this time around focus is on simplicity! You can print everything in PLA except the tires which are done in in a soft TPE such as NinjaFlex! Of course you can print it in any material you like but for those that want to print a car but only have PLA at hand, this is the project for you! This guide explains how to assemble the OpenRC F1 car.

30 Great 3D Printing Projects for Spring 2020. Anet A8 $4 Bed Leveling by VegasGuy. – OE2BLT ⨳ 40-20-10m EFHW Coil 3D Model. I was building multiband end fed antenna for 40-20-10m as per instructions on the Nonstop Systems web page Multiband End Fed by Frank N4SPP. I needed to build the loading coil, but the problem was that all materials were too heavy, they were putting excentric load on the fibre glass rod and I did not like the way how the antenna wire was connecting to the coil. How to Build a 3D Printer (The Ultimate Guide) Plotter : 6 Steps (with Pictures) - Instructables. I will be showing you two ways by which you can do this. Choose the method according to your convenience. DesigningProjectBox. Geeetech Prusa I3 Pro W 3D Printer building instruction. B1nQnnj KtS. Building a Stepper Motor Tester — Kronos Robotics. Download, Edit and Print Your Own Parts From McMaster-Carr : 7 Steps (with Pictures) - Instructables. The Creative Science Centre - by Dr Jonathan P. Hare.

A few years ago RS components gave me a Rep Rap Ormerod 3D printer (kit) and I have had a lot of fun exploring it to create a range of science based projects.Some of these are shown on this page and in the articles (PDF's etc.). The printer is now quite old (but still works ok) ... there is now a huge range of 3D printers available.video on 3D printing by RS Components ... I am in the video :-) CNC Machine With Camera and LED Backlight. (16) thang010146. ✂︎ HOME. Cable-Driven Robots May Lift European Industry - Futuris. Analog 3D printer - GIF - HomemadeTools.net. Modular DIY CNC Machine: 11 Steps. Since I live in an apartment and didn't have many tools when starting this project, I chose components based on their availability off the shelf or through online vendors. The project could probably be cheaper by cutting the extrusions yourself, using different suppliers, or different material completely, but I found this to be the easiest option.

Frame: The aluminum extrusions all come from 8020.net, which provides services for cutting and tapping of all extrusions. This means a chop saw for cutting metal isn't necessary since everything is already ordered to length. The T-slot extrusions are also fairly standard which means the hardware for them is easy to find and not proprietary to one single vendor.

Carriages and Drivetrain: The X and Y axes move using carriages which reduce friction and make it easy for attaching the extrusions, motors, and other electronics. For the Z-axis, I found it easiest to just design a carriage that would slide using the T-slots in the extrusions. 3D Printer News & 3D Printing News. Apr 4, 2017 | By Benedict. Meet 3 Robots That Could Be Changing the Construction Industry. OpenBuilds. Hybrid Virtual Environment 3D by Systèmes Hybridlab. Forum - Index. Pinterest. EWaste 60$ 3DPrinter: 11 Steps (with Pictures) Although the downloaded Marlin firmware already has a standard calibration for the axis resolution, you will have to go through this step if you want a precise printer. Here you will tell the firmware the steps per millimeter that your machine actually needs. This value depends on the steps per revolution of your motor and on the size of the thread in the driving rod of your axes.

By doing that we make sure that the movement of the machine actually corresponds to the distances in the g-code. Apollo-NG - picoPrint 3D Printer. Every Hackerspace or FabLab needs manufacturing capabilities in order to dramatically increase the edge of research and development possibilities. Embodied Computation: Exploring Roboforming for the Mass-Customization of Architectural Components by Alex Fischer. 3D Printer - Working Area 40x40x40cm - All. Frame materials:

Mechanical Engineering: Lead Screw and Nut Assemblies. Using OpenDesk.CC to Create CNC Furniture. My local makerspace, the Columbus Idea Foundry, has a ShopBot CNC router capable of handling 4×8’ sheets of plywood. When I discovered Opendesk’s web site with its downloadable plans for desks, tables, chairs and other furniture, I began to have ideas.

So when my daughter mentioned that she could use a kitchen table, that was all I needed to hear. I decided to create a table using the Opendesk “Meeting Table” design. By skipping the central hole (intended for cables), I’d have a perfectly functional kitchen table. Start the Project. I can watch this all day - GIF on Imgur. Laser Cutting An Enclosure To Compare To 3D Printing and Milling. There’s always a next step, a new opportunity to learn. For me, that’s the best part of being a maker. 1. Introduction — FlatCAM 8 documentation. A Raspberry Pi controlled mini CNC Laser engraver [last update Jan 18,2014] I recently made a mini CNC laser engraver using two DVD drives salvaged from old computers and <$10 extra parts bought on eBay.

Branch Technology. 131106 01 emmelmann tu hamburg. It’s Time For Direct Metal 3D-Printing. It’s tough times for 3D-printing. Stratasys got burned on Makerbot, trustful backers got burned on the Peachy Printer meltdown, I burned my finger on a brand new hotend just yesterday, and that’s only the more recent events. University of Oslo Master’s Student Creates Amazing Open Source 5-Axis 3D Printer. Space Frame Joint for Complex Structures - do it yourself.

3D Printing. Make Your Own 3D Printer Filament by Building Your Own Filament Extruder. Arduino Laser Engraver Wood Design! A DIY Bluetooth stylus that lets you wirelessly draw in 3D. Make your own Arduino-powered laser engraver at home. Students Invent A New Method Of 3-D Printing, Using UV Light. CNC Cutting/Routing Bits. HOW TO BUILD YOUR VERY OWN 8×8 LED MATRIX. Workshops. Benchtop DIY router plans. Mini CNC router, complete plans and instructions. Current & Future Projects. OpenBuilds. LASER - PLASMA BUILDS. OpenBuilds. Watch the Life-Like Motion of a Wooden Hummingbird Automaton. CNC Projects. A Simple CAD-CAM for 3 Axis Milling Machines. Drag Knife for CNC routerDonek Tools. Google Translate. Cnc project. Collections. Hypothetical workshop. 3d Printer, 3D Printing and 3doodler. Using Acetone to Smooth 3D Prints. Quite Amazing: Interesting way to build axis for 3D printers and cnc mills.

Stratum Networks Delta Robot. 3d printer, 3d printing and electronics. E3D Unveils Most Affordable 3D Printer Hotend Yet, The E3D Lite6 — Priced Under $32. 117 Pins on cnc router, 3d printer and 3d printing. Flux 3D: A cheap, modular 3D scanner, printer and laser engraver. Untitled. CNC Machine Kits. Q & A: Taking Dimensions From Photos.

Make your own cell phone charging power bank with 3-D printer, controller board, and lithium battery, 5V input, 5V output for charging 4.2V lithium ion and lithim polymer cells. 3D Printing Umbilical Cord Clamps in Haiti. DIY Filament Extruder. 3D Printing Andy Warhol. 3-D scanning, with your smartphone. Making Math 3D - Getting Smart by Megan Mead - 3D printing, edchat, EdTech, mathchat, Mathematics. Discov3ry Extruder Add-on – 3D Print in Sugar, Silicon, Ceramic & More For Under $350. 3D Printing - Marriott Library - The University of Utah. What Is 4-D Printing? [Video]