NEMA Motor. A NEMA 17 stepper motor.

The US-based National Electrical Manufacturers Association creates standards that are developed by the manufacturers through a voluntary consensus to provide descriptions of how things should be. NEMA ICS 16-2001 (Motion/Position Control Motors, Controls, and Feedback Devices) describes stepper motors and is the NEMA standard usually referred to when talking about the NEMA standard in the context of RepRap, stepper motors and 3D printers. In section 4.3.1.1 of that standard, NEMA chose to label stepper motors (e.g.

Pololu stepper driver board. Pololu stepper driver board Release status: working Please note: Pololu stepper driver boards has 0.05 ohm sense resistors instead of StepStick 0.2 ohm.

Pin Bed. Last Updated: 12th February 2012 My laser cutter came with a honeycombed panel which can be used to support sheet materials for cutting.

However, the mesh area is only 170x190mm and the nature of the honeycomb means that the beam frequently hits the edges of the mesh (which can lead to scorch marks on the underside of the material being cut). The honeycomb cells also tended to trap vapours and small bits of material that fall out of the work piece. Removing the top and bottom edges of the frame improved things as a) it allowed longer sheets to be placed on it and b) the slight gap this created under the top edge allowed (prior to my replacing the installed fan with head mounted fume extraction), vapours to be sucked out from below. Weistekengineering. Adventures in DIY Engineering: 40 Watt Chinese CO2 Laser Upgrade with RAMPS & Arudino. 3/31/2015 - Updates made in the Firmware and Inkscape plugin section below.

Thanks go to Turnkey Tyranny for the many improvements and fixes he's contributed. Also, I would like to note, there are many variations on the Laser supplies. Please be very aware whether yours is an ACTIVE LOW or ACTIVE HIGH enable signal. The firmware below is ACTIVE LOW. Introduction: I've wanted to start playing with Laser Cutter/Engravers for quite a while. Please excuse the picture quality, when I get some time I'll try to take better ones. Whats Needed: Build Thread Cheap 40W Ebay engraver/cutter (K40) upgrade thread - Page 4. Home made laser power meter. Identifying Unknown Plastics. This is a piece of free-burning ABS tubing showing characteristic flame color and smoke.

The burn test, as it’s known, correlates a plastic sample’s composition with a set of observable properties including… whether or not the material will freely burn in air when a gas ignition flame is removed,the color of the flame, the smell, the presence or absence of molten drips, andthe color and properties of any smoke, esp. the reactivity of smoke with wet litmus paper.

Though useful, the burn test should be used with caution of the toxicity of many plastic combustion products, and need not be a first resort when confronted with a sample of unknown polymer. To risk stating the obvious, the first step in identifying a piece of plastic should be to look for a label. Since 1988, the SPI resin identification coding system (Wikipedia) has been widely adopted by plastics manufacturers to label their products for post-consumer recycling. Laser Cutter Materials - ATXHackerspace. There are a wide range of materials that the Blue Laser Cutter can cut, etch or mark - but some simply don't work (eg metals) and some are extremely hazardous to either humans or the machine itself (eg PVC and ABS).

It is therefore imperative that you check these lists before attempting to cut materials that you have not worked with before. It is not always obvious which materials will work - for example: Polycarbonate/Lexan produces flames and lethal chlorine gas which will rapidly corrode this $40,000 machine into uselessness and which is extremely hazardous to the health of people nearby. Yet Acrylic - which looks, smells, feels and tastes just like Lexan - cuts smoothly and cleanly and is one of the best materials to use with the laser! So check and double-check what you're cutting. Where to Find Materials There is a fairly good supply of materials at the hackerspace, which you can pay for in the store. Where to find materials to feed the laser.

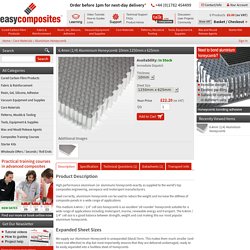

Safe Materials Cutting. 6.4mm (1/4) 3000 Alloy Aluminium Honeycomb to Buy Online - Easy Composites. Product Description High performance aluminium (or aluminum) honeycomb exactly as supplied to the world's top composites engineering, aerospace and motorsport manufacturers.

Used correctly, aluminium honeycomb can be used to reduce the weight and increase the stiffness of composite panels in a wide range of applications: This medium 6.4mm / 1/4" cell size honeycomb is an excellent 'all rounder' honeycomb suitable for a wide range of applications including motorsport, marine, renewable energy and transport. The 6.4mm / 1/4" cell size is a good balance between strength, weight and cost making this our most popular aluminium honeycomb. Expanded Sheet Sizes We supply our Aluminium Honeycomb in unexpanded (block) form. The sheets are available to buy 'off the shelf' in blocks which will expand to a full sheet size of 2500mm x 1250mm or to a smaller sheet size of 1250mm x 652mm. CO2 laser cutter. 03/05/13: See here for a measurement of the output power using a thermal technique 19/11/13: I discovered I can do laser wire stripping!

Introduction I had been considering buying a laser cutter/engraver for several months, mainly attracted by the possibility of engraving designs into wooden boxes, ceramic tiles, glass etc. Any of the "Western" models were far too expensive (e.g. £17,000 for a Trotec engraver) so I therefore settled on a Chinese model, which are readily available on EBay. I initially contacted HPC Laser (www.hpclaser.co.uk) who are a UK distributor of Chinese machines. The machine is an SG40A Desktop Laser Engraver, made by Signstech International (aka "Strong Signs Digitech"). I have put more specific details and specs of the machine, including hi-resolution photos of the insides of the machine, on this page. Safety. Laser Cutter. Gallery For a while I'd been noticing how cheap lasercutters had become on Ebay.

I'd considered putting one on my list of 'things to look at when I next fancied a new toy', but was initially discouraged by some mixed opinions I'd read. My only immediate application would be for making SMD paste stencils, but I'm sure I could find other uses... Eventually I succumbed to temptation.

Amongst the various Ebay sellers selling them, it was obvious by looking at other items they were selling that many (especially the Hong Kong ones) were just box-shifters, also selling all sorts of random stuff. As expected, documentation (including video on CD supplied) was as appalling as we've come to expect from Chinese suppliers. Buying a Laser Cutter from China (Part One)… 2012 UPDATE: Check out the new laser cutter I built from scratch here -> New 24×18″ CO2 Laser Since building the CNC router last year I’ve become increasingly interested in adding a laser cutting/engraving head.

Sam's Laser FAQ - Carbon Dioxide Lasers.